A method for thermal regeneration of waste rubber

A waste rubber, thermal regeneration technology, applied in the preparation of liquid hydrocarbon mixture, treatment of hydrocarbon oil, petroleum industry, etc., can solve the environmental pollution of incoming and outgoing materials, the high price of environmentally friendly softeners, and the lack of regenerated rubber hydrocarbon composition products Evaluation plan and other issues to achieve the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

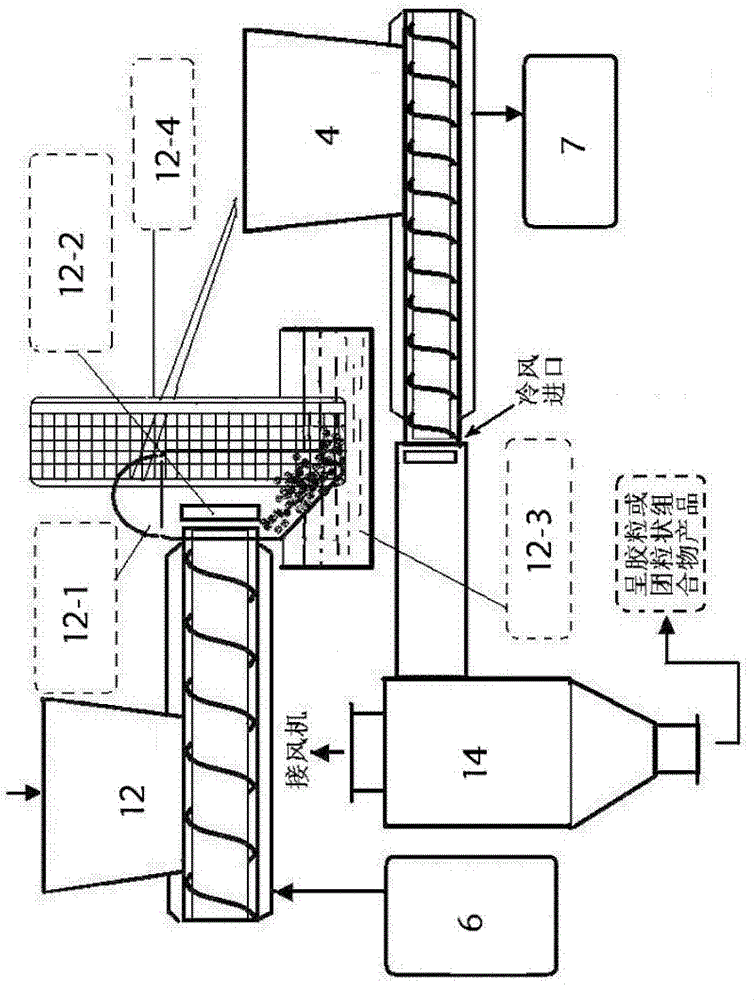

Image

Examples

Embodiment 1

[0169](1-1) Preparation: Take 100 parts by weight (hereinafter referred to as "parts") of the rubber coarse powder of the tire top part of the waste tires that have been removed from the fibers and steel wire impurities, and can be operated in a closed manner. The materials are introduced into a closed stirring heating tank one by one, and some formulation auxiliaries such as softeners that meet environmental protection requirements are added first, and some formulation auxiliaries are added first. The composition is: 150 parts of softeners, specifically including: environmental protection 15 parts of type rubber filler oil, 67 parts of No. 30 motor oil, 10 parts of paraffin wax, 28 parts of stearic acid; 3 parts of antioxidant, the variety used: 2,6-di-tert-butyl-p-cresol; 13 parts of water. The softener can be pre-heated and mixed, and then metered by a pump. The order of feeding waste rubber coarse powder and formulation auxiliaries can be reversed, especially if water is a...

Embodiment 2

[0176] (2-1) Preparation: Take 100 parts of the 20-40 mesh sieve waste tire rubber coarse powder that has been removed from fibers and steel wire impurities, introduce it into a closed stirring heating tank, and first add a softener that meets environmental protection requirements and other formulation auxiliaries, the first part of the formulation auxiliaries is added, which is composed of: 32 parts of softener, specifically including: 10 parts of environmentally friendly rubber filler oil, 16 parts of No. 40 engine oil, 4 parts of paraffin wax, 2 parts of stearic acid parts; 3 parts of antioxidant, the variety used: 2,6-di-tert-butyl-p-cresol; 13 parts of water. The feeding sequence of the waste rubber coarse powder and formulation auxiliaries can be reversed. The environmental softening agent in the formulation auxiliary, the weight ratio of waste rubber coarse powder to it is 100 / 32. After the charging is completed, close the charging door, open the intake and exhaust val...

Embodiment 3

[0182] (3-1) Preparation: 100 parts of the crude rubber granules of waste butyl water tires with a size of about 5 meshes are introduced into a closed stirring heating tank, and some formulation auxiliaries such as softeners that meet environmental protection requirements are added first. Said first adding part of the formulation auxiliary, which consists of: 55.5 parts of softener, specifically including: 26 parts of environmentally friendly rubber filler oil, 10 parts of paraffin wax, 6.5 parts of microcrystalline wax, 13 parts of stearic acid; 13 parts of water. The feeding sequence of the waste rubber coarse powder and formulation auxiliaries can be reversed. The environmental softening agent in the formulation auxiliary, the weight ratio of waste rubber coarse powder to it is 100 / 55.5. After the charging is completed, close the charging door, open the intake and exhaust valves, first fill with nitrogen to drive out the oxygen-containing air brought into the tank from the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength at break | aaaaa | aaaaa |

| tensile strength at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com