Method for preparing thermally stable slowly digestible starch

A slow-digestible starch, thermostability technology, applied in food preparation, food science, fermentation and other directions, can solve the problems of difficult application, slow-digestible starch does not have thermostability, slow digestibility and other problems, to improve insulin activity, It has the effect of thermostability, anti-enzyme activity and insulin activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] 1kg of starch raw material, add 50kg of water to make a 2% starch solution. In the enzymolysis pot, add pullulanase (enzyme amount 1U / g, calculated as starch) at 50°C and pH 5.0, stir, and enzymolyze for 4 hours; add 20g of tea polyphenols and mix; heat to Inactivate the enzyme at 100°C for 15 minutes, then cool to room temperature. The enzymolysis solution is homogenized by a high-pressure homogenizer at 20 MPa, and then introduced into a spray dryer (inlet air temperature 160°C, outlet air temperature 100°C) and dried into powder. Packaging, that is to get the finished product.

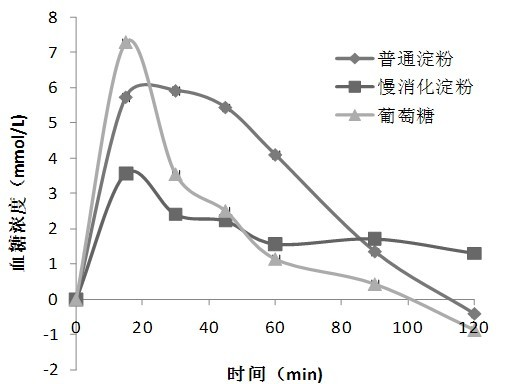

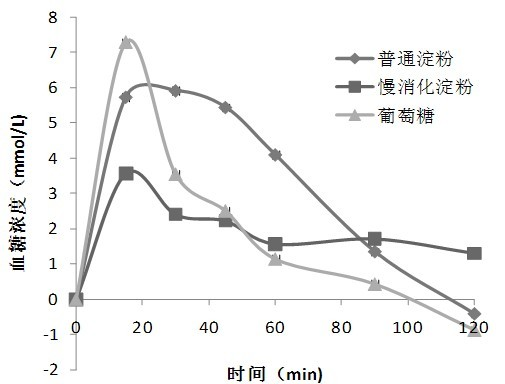

[0013] The content of amylose in the slow-digesting starch product prepared by the present invention is greater than 40%; the digestibility of the slow-digesting starch product is measured in vitro by the Englyst method, and obtained figure 1 digestion curve, figure 1 It can be seen that compared with starch raw materials, slowly digestible starch products have a lower digestibility (less ...

Embodiment 2

[0016] Add 1kg of starch raw material to 30kg of water to make about 3% starch solution. In the enzymolysis pot, add pullulanase (enzyme amount 2U / g) at 50°C and pH 5.0, stir, and enzymolyze for 8 hours; add 50g of tea polyphenols and mix; heat to 100°C to inactivate the enzyme 15min, cooled to room temperature. The enzymolysis solution is homogenized by a high-pressure homogenizer at 20 MPa, and then introduced into a spray dryer (inlet air temperature 180°C, outlet air temperature 90°C) and dried into powder. Packaging, that is to get the finished product.

Embodiment 3

[0018] Add 1kg of starch raw material to 20kg of water to prepare a 5% starch solution. In the enzymatic hydrolysis pot, add pullulanase (enzyme amount 5U / g) at 50°C and pH 5.0, stir, and enzymatically hydrolyze for 10 hours; add 80g of tea polyphenols and mix; heat to 100°C to inactivate the enzyme 15min, cooled to room temperature. The enzymolysis solution is homogenized by a high-pressure homogenizer at 20 MPa, and then introduced into a spray dryer (inlet air temperature 200°C, outlet air temperature 80°C) and dried into powder. Packaging, that is to get the finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com