Method for preparing polycarbonate with continuous two-phase interface phosgene method

A polycarbonate and phase interface technology, which is applied in the field of continuous two-phase interface phosgene preparation of polycarbonate, can solve the problems of large consumption of phosgene and lye, complicated process, and increased difficulty of the preparation process, so as to reduce unit consumption , Simplify the process control steps, reduce the effect of phosgene alkaline hydrolysis rate and the amount of lye added

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

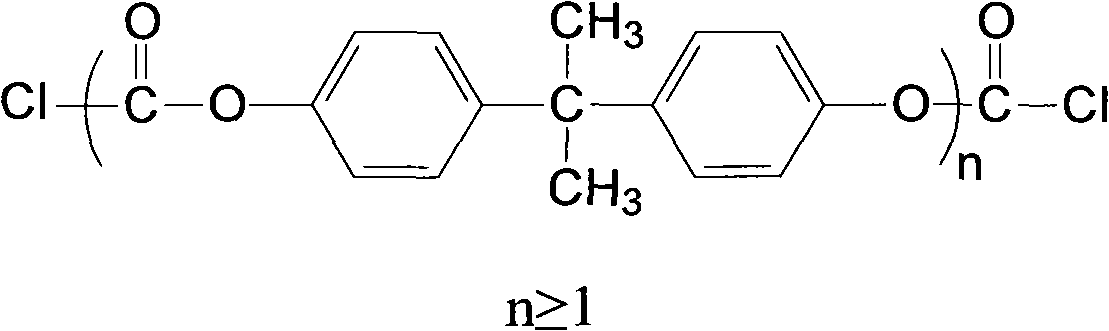

Image

Examples

Embodiment 1

[0049] Add 1,801g of bisphenol A, 9,558g of water, and 660g of sodium hydroxide to a mixing tank, mix and dissolve to form a sodium phenoxide brine phase; add 850g of liquid phosgene and 13,203g of dichloromethane to another mixing tank, and mix to form an organic phase. The sodium phenolate brine phase and the organic phase, which accounted for 99% of the total amount of the bisphenol A sodium brine phase, were injected into the photochemical reactor composed of a static mixer at a flow rate of 397g / min and 468g / min, and entered after staying for 1.5min. Also in the coupling reactor that is made of static mixer, in the reactor, inject the sodium phenate brine phase of remainder, concentration simultaneously and be the end-capping agent of 5wt%, described end-capping agent is p-tert-butylphenol Dichloromethane solution, concentration are the catalyzer of 1.5wt%, and described catalyzer is the dichloromethane solution of triethylamine and the sodium hydroxide solution that conce...

Embodiment 2

[0051] Add 1,802g of bisphenol A, 9,560g of water, and 660g of sodium hydroxide to a mixing tank, mix and dissolve to form a sodium phenoxide brine phase; add 850g of liquid phosgene and 13,205g of dichloromethane to another mixing tank, and mix to form an organic phase. The sodium phenolate brine phase and the organic phase, which account for 99.5% of the total amount of the bisphenol A sodium brine phase, are injected into the photochemical reactor composed of a static mixer at a flow rate of 399g / min and 468g / min, and enter after staying for 1.5min. In the coupling reactor that is also constituted by a static mixer, inject the remaining amount of sodium phenolate salt phase, 5% mass fraction of end-capping agent p-tert-butylphenol / dichloromethane solution, 1.5% mass fraction into the reactor simultaneously. Fractions of catalyst triethylamine / dichloromethane solution and 30% mass fraction of sodium hydroxide solution, the flow rates of the four are 2g / min, 12.8g / min, 7g / min,...

Embodiment 3

[0053]Add 1,802g of bisphenol A, 9,559g of water, and 660g of sodium hydroxide to a mixing tank, mix and dissolve to form a sodium phenoxide brine phase; add 849g of liquid phosgene and 13,202g of dichloromethane to another mixing tank, and mix to form an organic phase. The sodium phenolate brine phase and the organic phase, which accounted for 95% of the total amount of the bisphenol A sodium brine phase, were injected into the photochemical reactor composed of a static mixer at a flow rate of 381g / min and 468g / min, and entered after staying for 1.5min. In the coupling reactor that is also constituted by a static mixer, inject the remaining amount of sodium phenolate salt phase, 5% mass fraction of end-capping agent p-tert-butylphenol / dichloromethane solution, 1.5% mass fraction into the reactor simultaneously. Fractions of catalyst triethylamine / dichloromethane solution and 30% mass fraction of sodium hydroxide solution, the flow rates of the four are 20g / min, 12.8g / min, 7g / m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Weight average molecular weight | aaaaa | aaaaa |

| Weight average molecular weight | aaaaa | aaaaa |

| Weight average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com