Polycarboxylic-acid copolymer dispersant and preparation method thereof

A technology of copolymer and polycarboxylic acid, applied in the field of superplasticizer, new polycarboxylate high-performance water reducer and its preparation, can solve problems such as poor slump retention performance, and achieve good concrete slump and The effect of fluidity, high concrete water reduction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

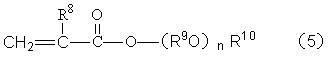

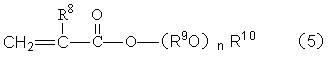

Method used

Image

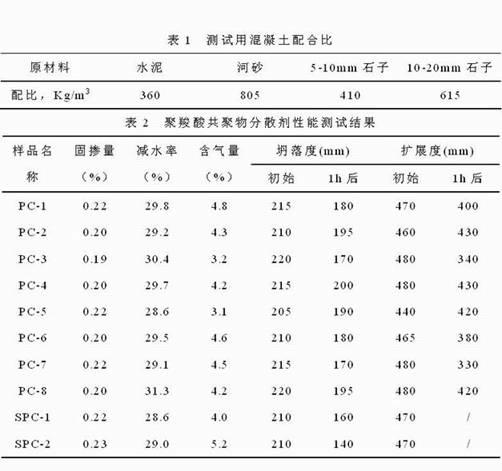

Examples

Synthetic example 1

[0052] Put 132.0g of 3-allyloxy-1,2-propanediol and 2.0g of catalyst sodium methoxide into a 2L reactor, replace the reactor with nitrogen, stir and raise the temperature to 105°C~115°C, vacuumize to remove water and Methanol, the vacuum pressure is above negative 0.09MPa, and the vacuum time is 30 minutes. After stopping vacuuming, add a small amount of ethylene oxide from the top of the reactor until the pressure of the reactor rises to about 0.10MPa; The speed is to keep the pressure in the reactor between 0.30MPa and 0.40MPa, and the reaction temperature is maintained at 105°C to 115°C by adjusting the cooling water, and the cumulative weight of ethylene oxide added is 1760g. After all the ethylene oxide is added, continue the heat preservation reaction at 105°C to 115°C for more than 30 minutes until the pressure in the reactor no longer drops, then cool down to 50°C to 60°C and discharge to obtain unsaturated polyether monomer, record for A-1.

Synthetic example 2

[0054] Put 73.0g of 3-(2-methallyloxy)-1,2-propanediol and 1.0g of catalyst sodium methoxide into a 2L reactor, replace the reactor with nitrogen, and stir to raise the temperature to 130℃~140℃ , vacuumize to remove water and methanol, the vacuum pressure reaches minus 0.09MPa, and the vacuum time is 30 minutes. After stopping vacuuming, add a small amount of ethylene oxide from the top of the reactor until the pressure of the reactor rises to about 0.10MPa; The speed is to keep the pressure in the reactor between 0.30MPa and 0.40MPa, and the reaction temperature is maintained at 130°C to 140°C by adjusting the cooling water, and the cumulative weight of ethylene oxide added is 1760g. After all the ethylene oxide is added, continue the heat preservation reaction at 130°C to 140°C for more than 30 minutes until the pressure in the reactor no longer drops, then cool down to 50°C to 60°C and discharge to obtain unsaturated polyether monomer, record for A-2.

Synthetic example 3

[0056] Put 73.0g of 3-(2-methallyloxy)-1,2-propanediol and 2.0g of catalyst sodium amide into a 2L reactor, replace the reactor with nitrogen, and stir to raise the temperature to 140℃~150℃ , Vacuum out water and ammonia, the vacuum pressure reaches minus 0.09MPa or more, and the vacuum time is 30 minutes. After stopping vacuuming, add a small amount of mixture of ethylene oxide and propylene oxide from the top of the reactor (the molar ratio of ethylene oxide and propylene oxide is 95:5), until the pressure of the reactor rises to about 0.10MPa; After the pressure of the kettle falls back, continue to feed the mixture of ethylene oxide and propylene oxide at a slow speed (the mass ratio of ethylene oxide and propylene oxide is 95:5), and the speed of feeding the epoxy mixture is to keep the reaction The pressure in the kettle is between 0.30MPa and 0.40MPa, and the reaction temperature is maintained at 140°C to 150°C by adjusting the cooling water, and the cumulative weight o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Nominal particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com