Resist coating and developing apparatus and method

A development device and development method technology, applied in photography, photoplate making process coating equipment, optics, etc., can solve the problems of deterioration of integrated circuit characteristics, large line width roughness, and failure to work normally

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Hereinafter, embodiments of the present invention will be described with reference to the drawings, but the present invention is not limited to the illustrated embodiments. In all the drawings, the same or corresponding reference signs are assigned to the same or corresponding components or components, and repeated explanations are omitted.

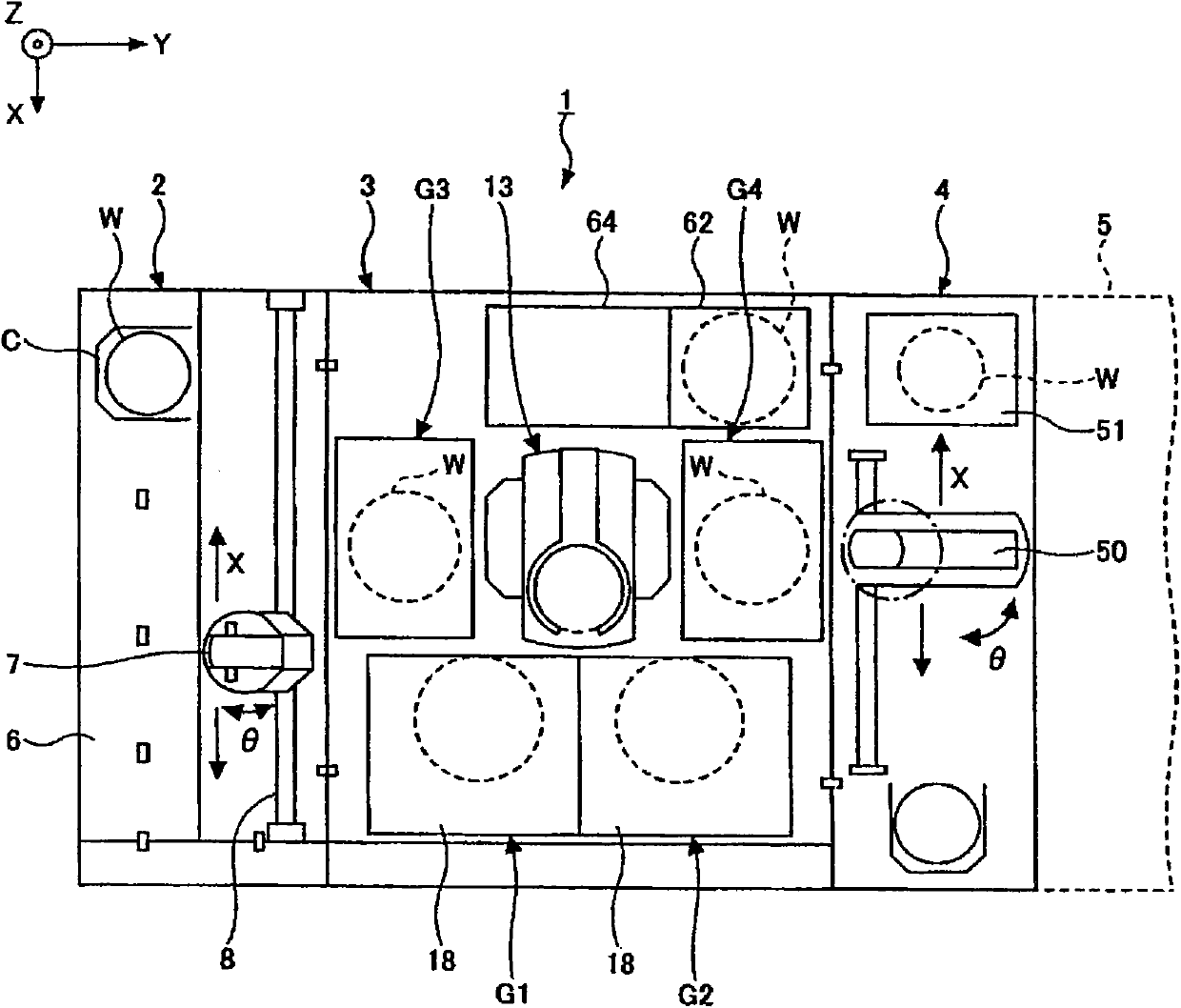

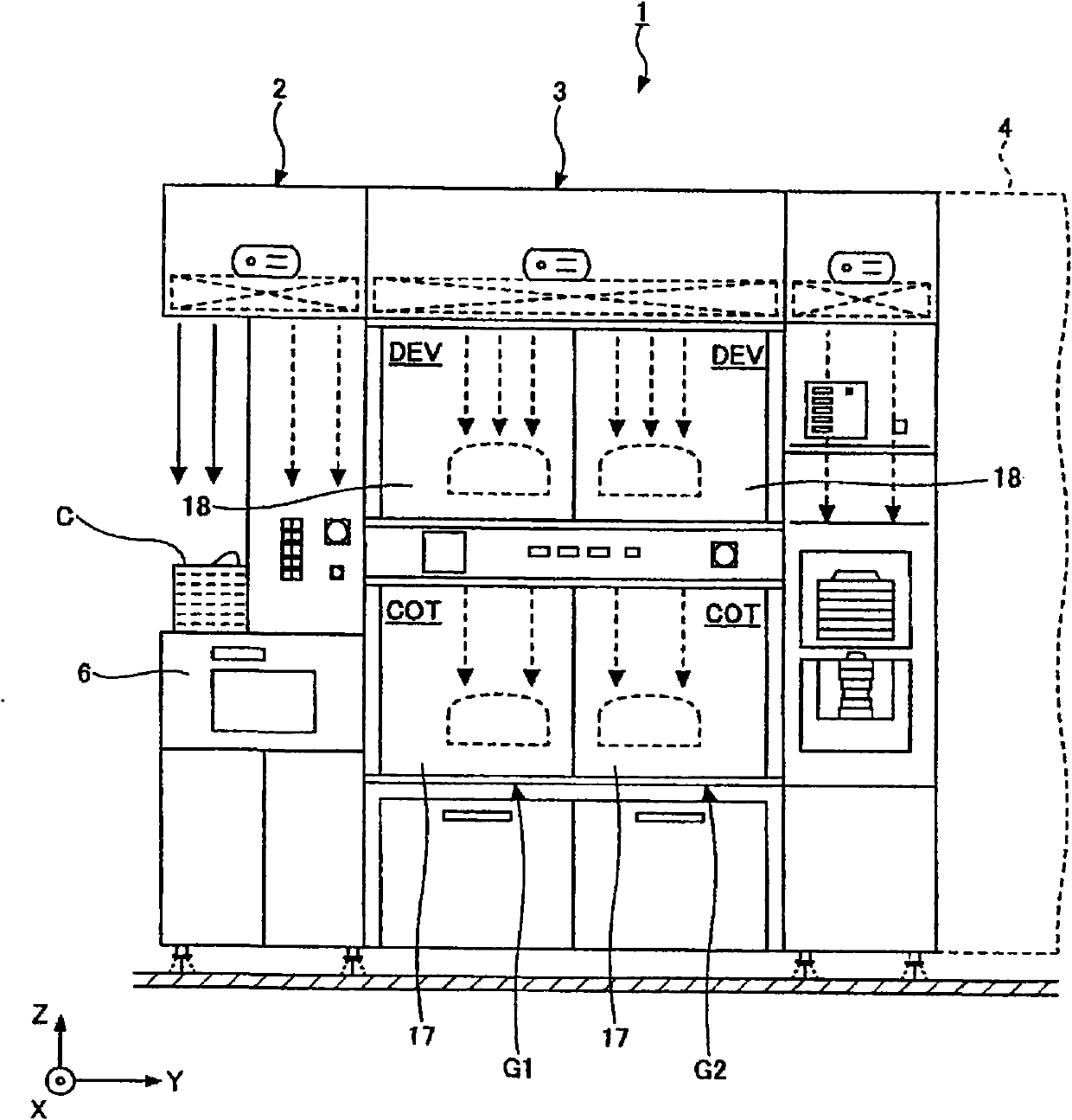

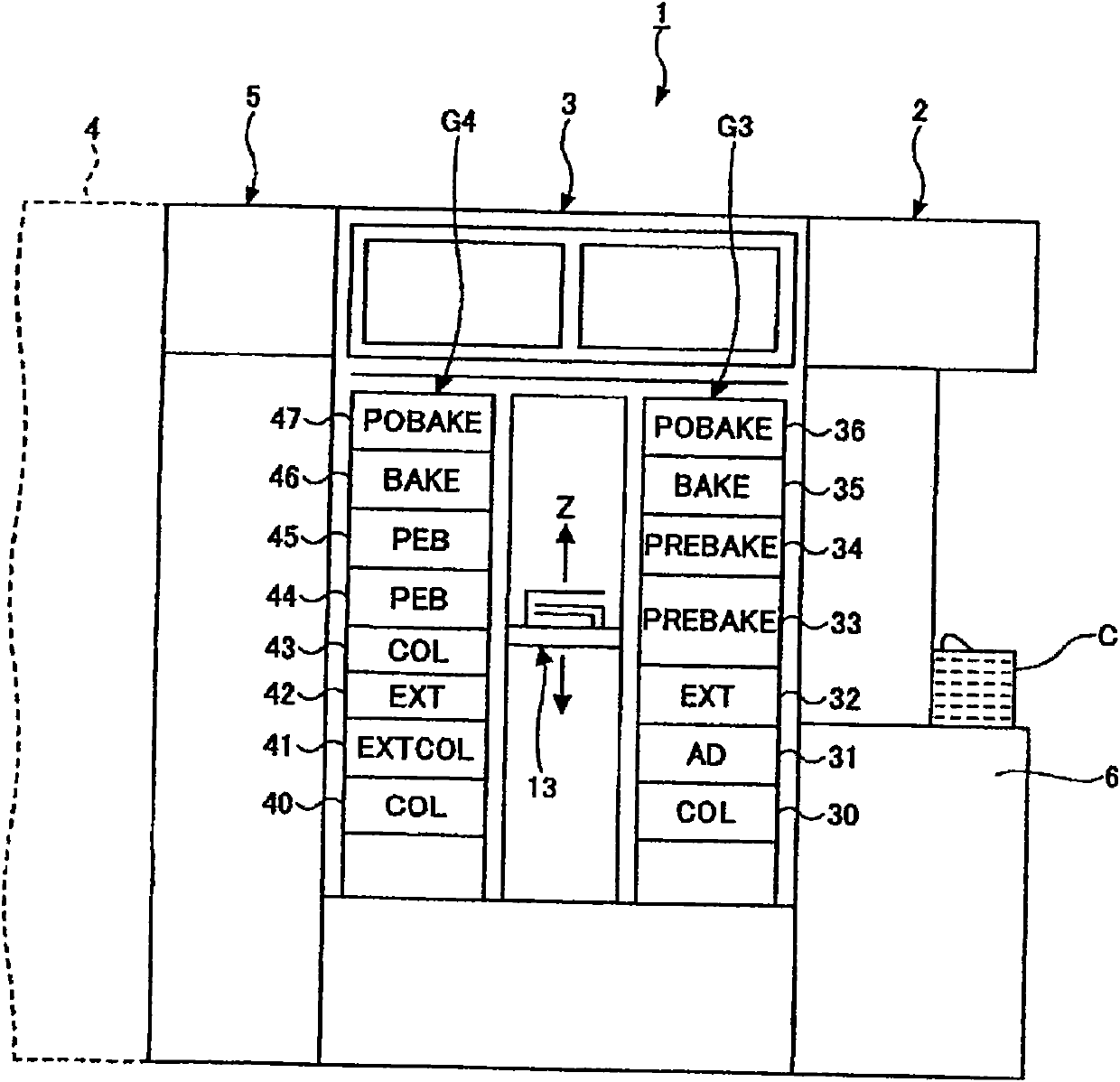

[0026] figure 1 is a schematic plan view showing the structure of a resist coating and developing device 1 according to an embodiment of the present invention, figure 2 is a schematic front view of the resist coating and developing device 1, image 3 It is a schematic rear view of the resist coating and developing device 1 .

[0027] Such as figure 1 As shown, a resist coating and developing apparatus 1 has a cassette loading and unloading station 2 , a processing station 3 and an interface unit 4 .

[0028] The cassette loading and unloading table 2 has a mounting portion 6 on which a cassette C containing, for example, 25 wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com