Plastic coated metal pipe joint

A metal pipe and plastic-coated technology, which is applied in the direction of pipe/pipe joint/pipe fitting, sleeve/socket connection, passing components, etc., can solve the problems of high cost of metal joints, sealing of metal joints and plastic boxes, and difficult life problems, etc. , to achieve the effects of easy welding, good sealing performance and high joint strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing, the present invention is described in detail:

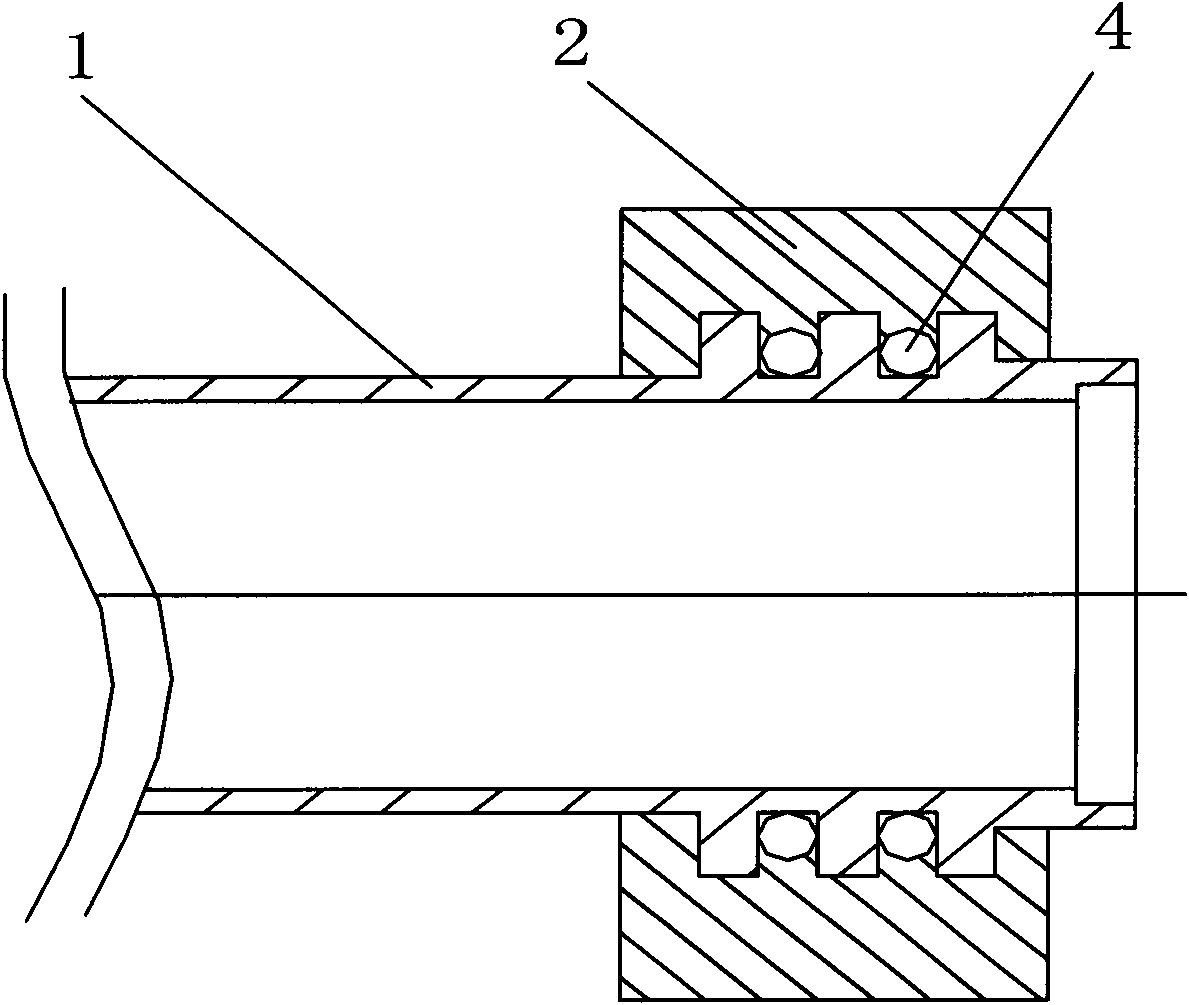

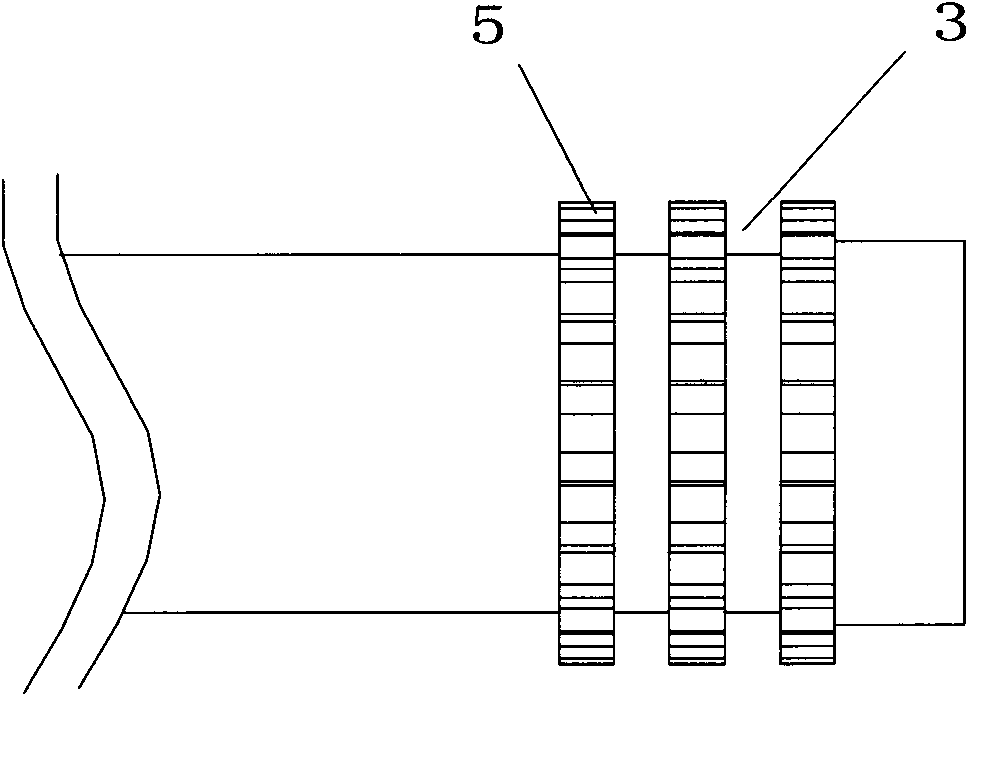

[0015] like figure 1 As shown, the plastic-coated metal pipe joint body 1 of the present invention and the plastic sleeve 2 coated on one end connected with the plastic water tank, wherein the metal pipe joint body 1 can process a fitting groove 3 at the end of its injection molding, and the fitting groove Place sealing ring 4 inside, see figure 2 , so that during injection molding, the plastic sleeve and the sealing ring form an integral plastic sleeve and are embedded in the metal pipe joint body 1, which can not only greatly improve the sealing performance, but also make the plastic sleeve and the pipe joint body 1 more reliable, without It will slip off under the action of external force.

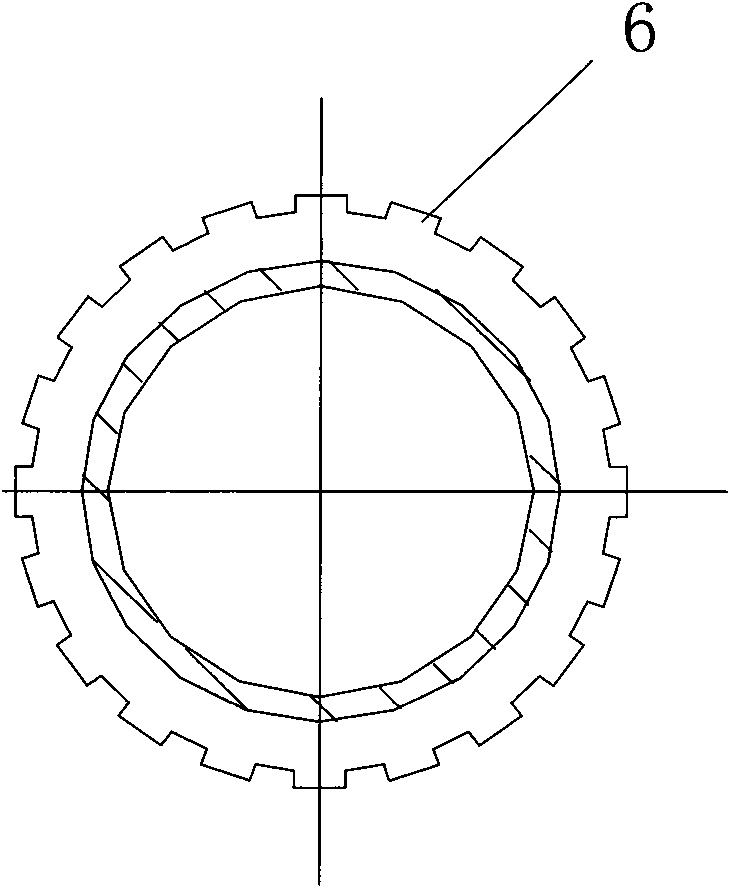

[0016] In this embodiment, three serrated fixed teeth are designed on the protrusion 5 of the plastic-coated part of the metal joint body 1. The structure of the teeth can be sawtoo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com