Magnetically-controlled plasma welding method and welding device

A technology of plasma and welding methods, which is applied in the field of plasma welding methods and welding devices, and can solve problems such as failure to achieve expected results and weakening of the magnetic field.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

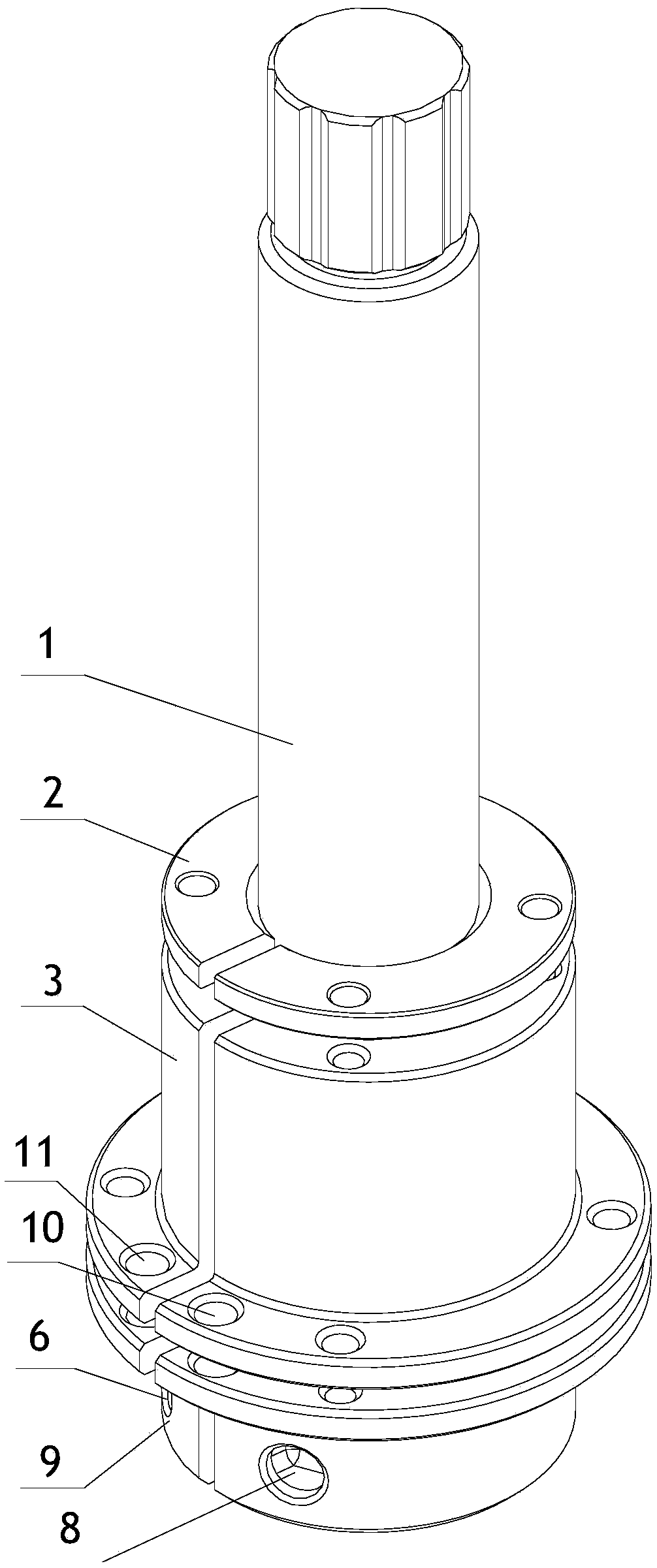

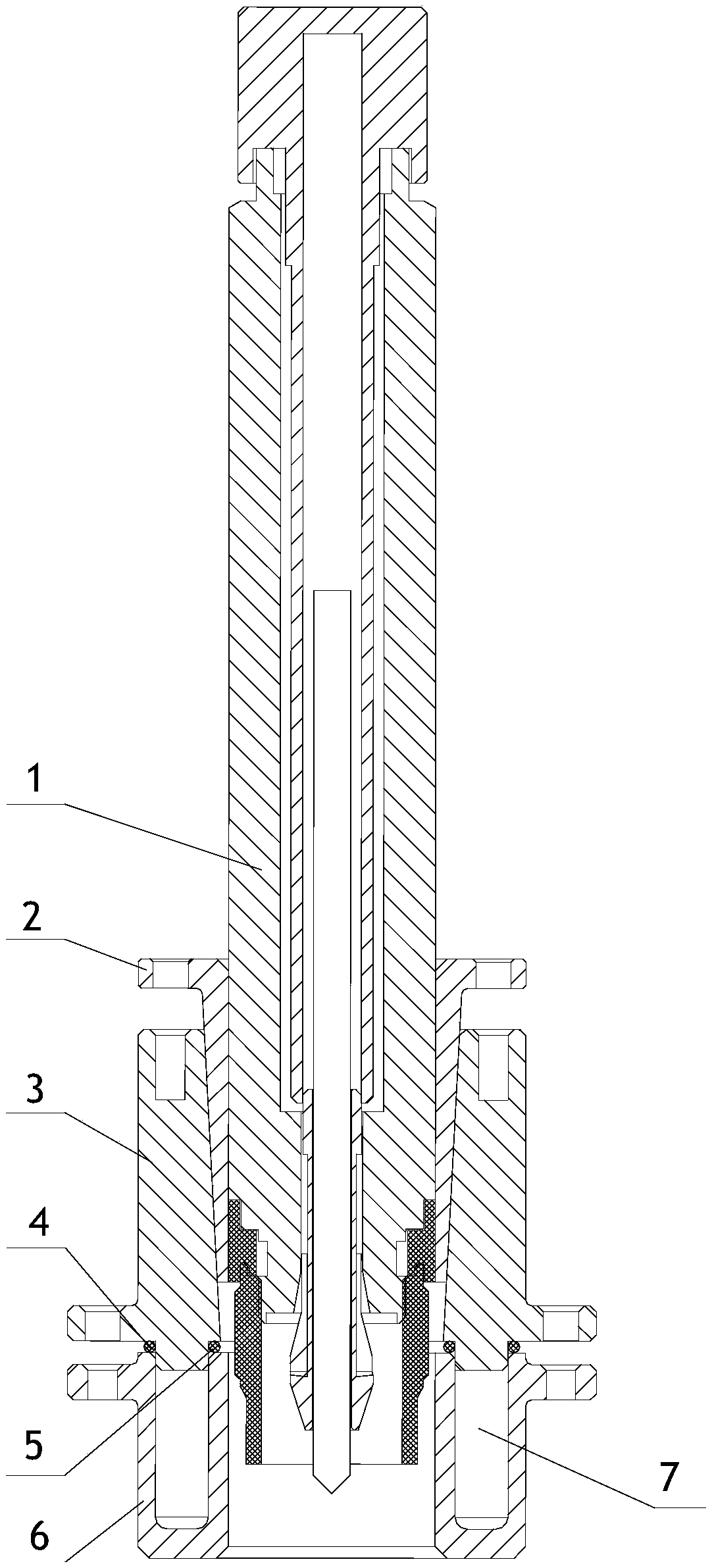

[0023] A magnetron plasma welding method proposed in this embodiment increases a longitudinal magnetic field along the direction of the welding torch between the welding torch and the welding workpiece.

[0024] In this embodiment, the longitudinal magnetic field along the direction of the welding torch may have weak magnetic fields in other directions at the same time, as long as the shrinkage effect of the longitudinal magnetic field on the arc is not affected.

[0025] The longitudinal magnetic field along the direction of the welding torch used in this embodiment is formed by a metal ring connected to a power supply, which may be a DC power supply or an AC power supply. The current of the power supply is 100-20000A. The current of the power supply is determined according to the material of the welding workpiece and the welding thickness. For welding a slightly thin workpiece, you can choose a current of several hundred amperes. For difficult welding or thick welding, you ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com