Oil supply device of sewing machine

An oil supply device, sewing machine technology, applied in sewing machine components, sewing equipment, lubrication/cooling devices, etc., can solve the problems of easy oil leakage, increased cost, large size, etc., and achieve the effect of preventing wear and tear and preventing melting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

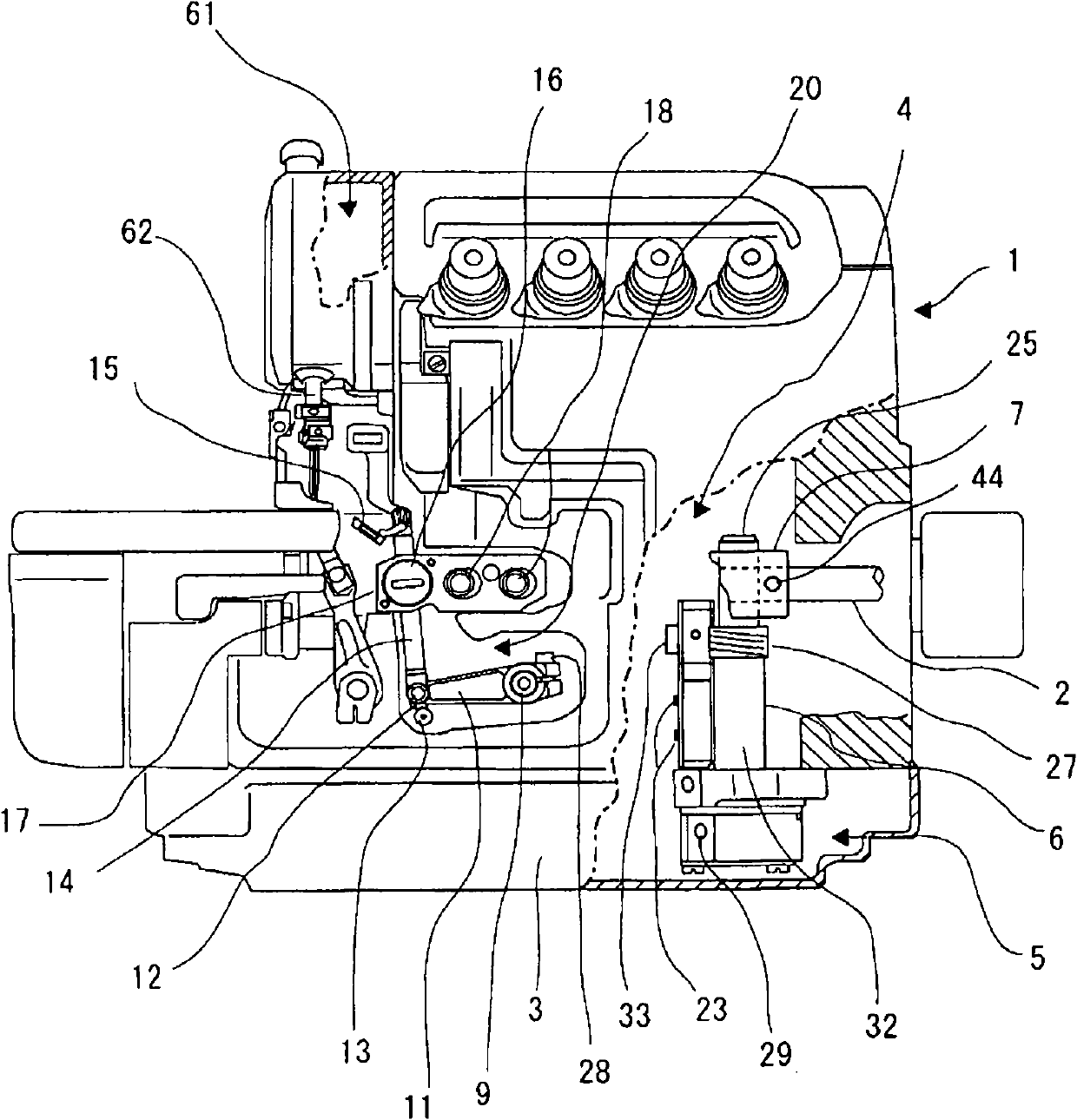

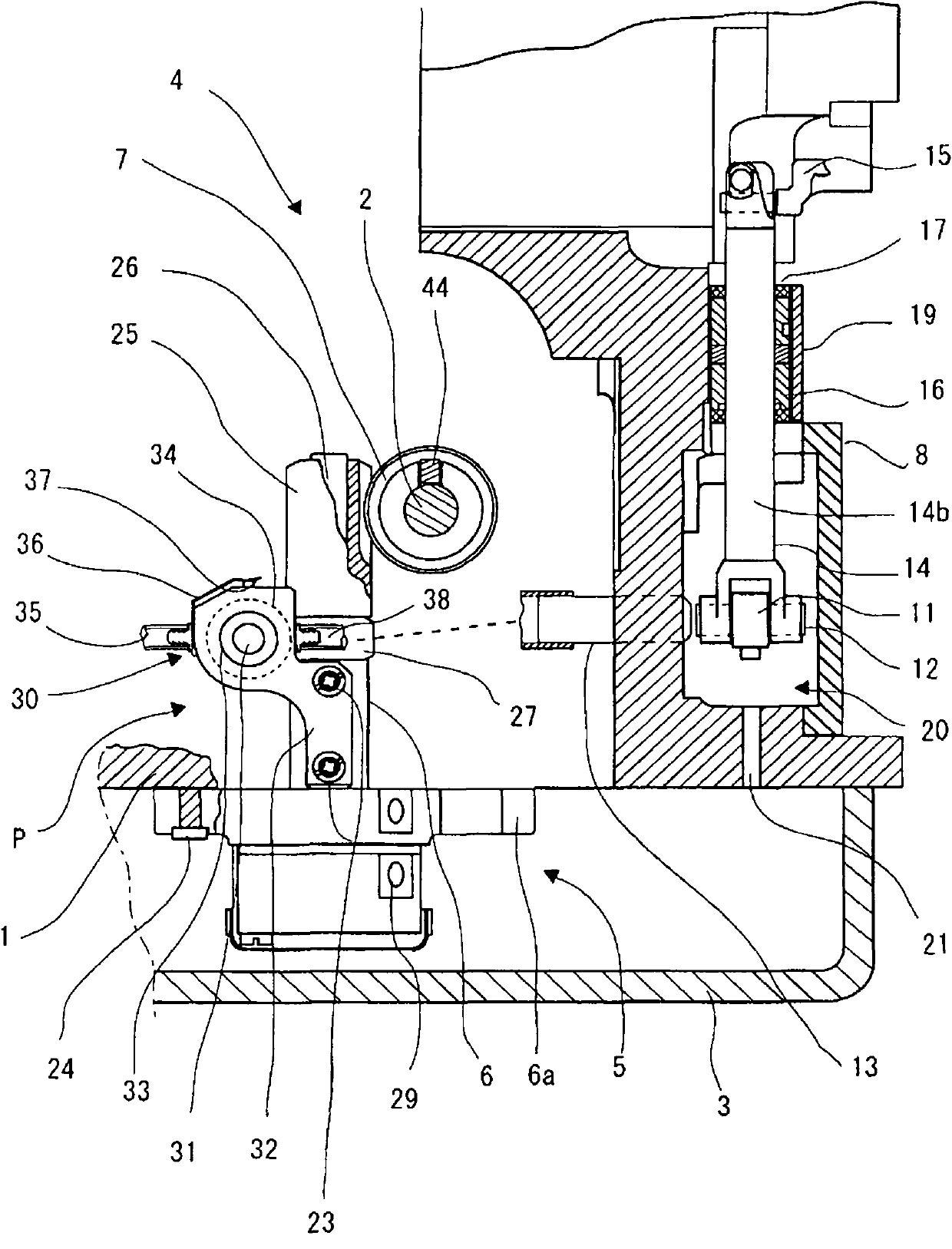

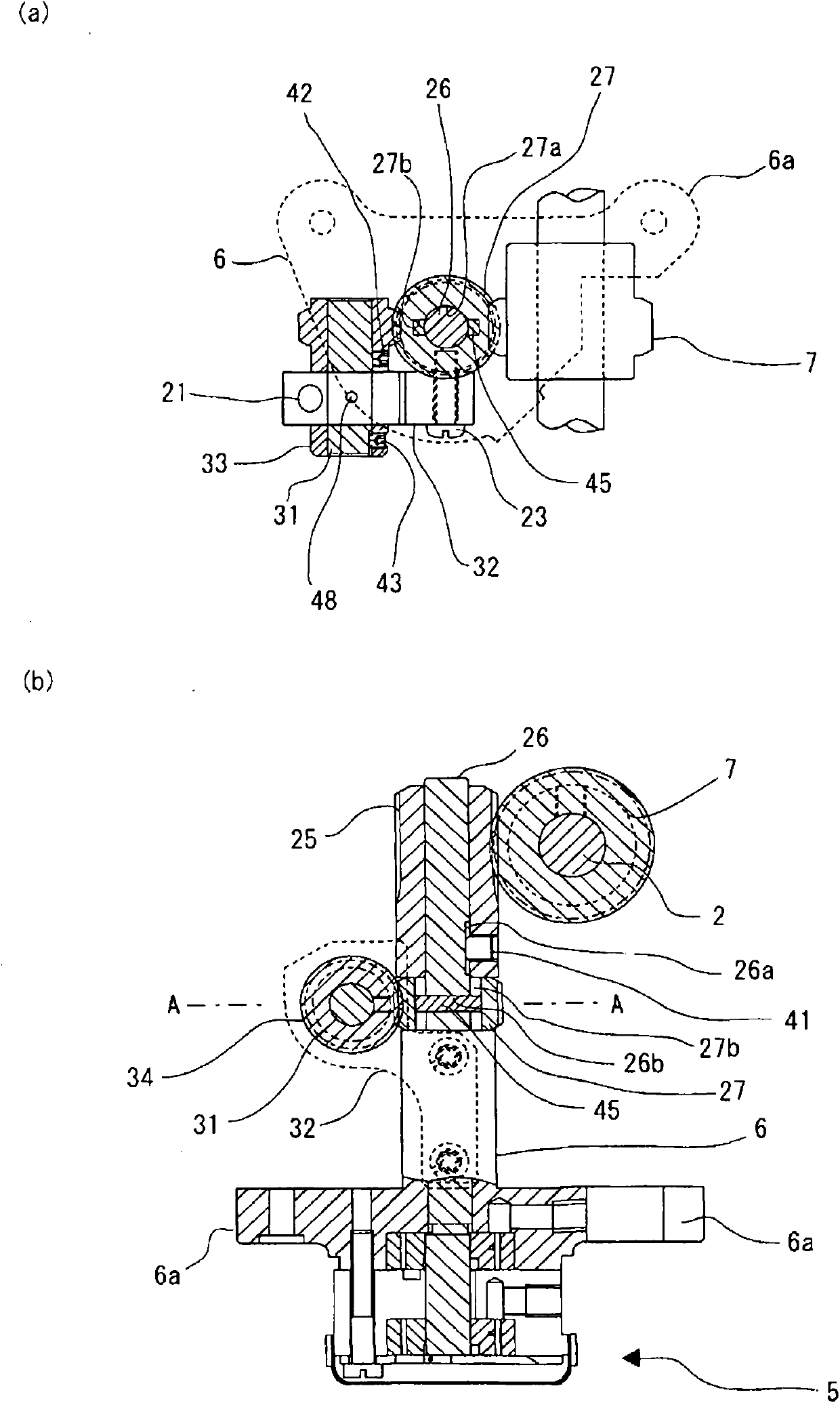

[0056] Hereinafter, embodiments of the present invention will be described based on the drawings. figure 1 It is a front view showing a partially cutaway overlock sewing machine to which the present invention is applied. figure 2 is seen from the left side figure 1 Partial sectional view of the main part of the oil supply device of the sewing machine. In addition, in figure 1 In , the cover 8 provided on the front surface of the second airtight chamber 20 is omitted to show its internal mechanism.

[0057] In the first airtight chamber 4 communicated with the oil pocket 3 and formed in the frame 1 , the main shaft 2 is horizontally arranged and rotatably supported by the frame 1 . In front of the frame 1 , a second airtight chamber 20 is provided in connection with the first airtight chamber 4 , and the front surface of the second airtight chamber 20 is covered with a cover 8 . The main shaft 2 is connected to the upper looper shaft 9 via a known upper looper driving mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com