Method for preparing magnetic nanotube

A magnetic nanometer and nanotube technology, applied in chemical instruments and methods, single crystal growth, polycrystalline material growth and other directions, can solve problems such as poor control of nanotubes, achieve good promotion and application value, controllable morphology, Effects of Simple Synthesis Techniques

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

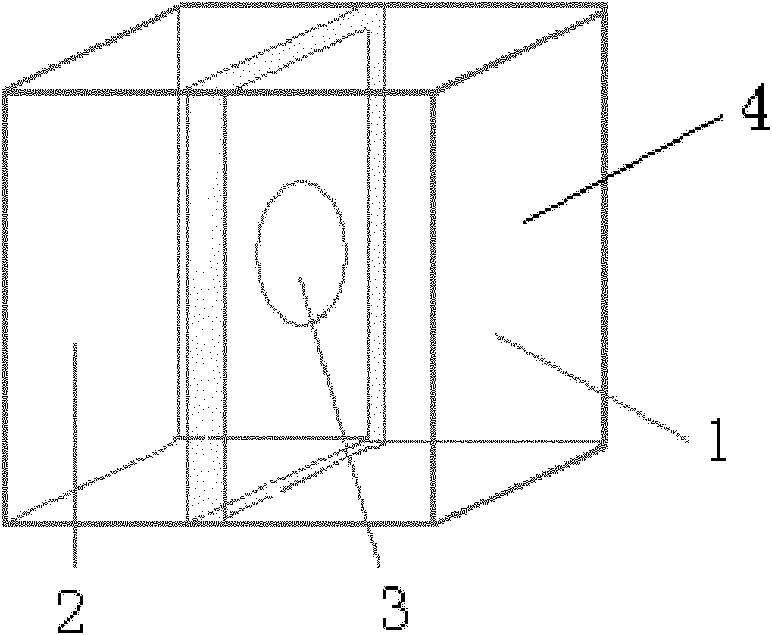

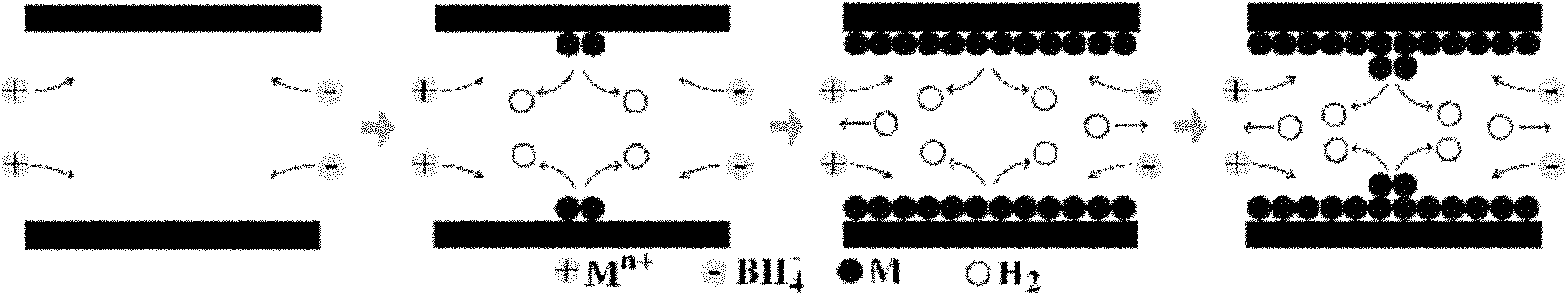

[0027] Take a purchased 200nm aluminum oxide film 3 and place it in the middle of two quartz reaction cells 1, and inject a concentration of 0.08mol / L CoSO into one quartz reaction cell 4 Solution 2, inject 10g / L sodium borohydride aqueous solution 4 into another quartz reaction cell, let it stand for 8 minutes at room temperature, take off the black nanotube / alumina composite film, and then clean the composite film with distilled water and absolute ethanol 3- 4 times, put into a vacuum drying oven at room temperature and dry to constant weight, partially dissolve with 2mol / L NaOH and use a scanning electron microscope to detect the topography of the nanotube array ( image 3 ); immerse in 2mol / L NaOH for 48 hours until the aluminum oxide film is completely dissolved, then centrifugally wash with distilled water until the pH is neutral, and finally rinse twice with absolute ethanol, put it in a vacuum drying oven at room temperature and dry to constant weight, then Amorphous m...

Embodiment 2

[0029] Take a piece of purchased 200nm aluminum oxide film and place it in the middle of two quartz reaction cells, and one quartz reaction cell is injected with a concentration of 0.06mol / L NiSO 4 Solution, inject 8g / L sodium borohydride aqueous solution into another quartz reaction tank, let it stand for 10 minutes at room temperature, remove the black nanotube / alumina composite film, and then wash the composite film with distilled water and absolute ethanol for 3-4 times , put into a vacuum drying oven at room temperature and dry to constant weight, partially dissolve with 2mol / L NaOH, and use a scanning electron microscope to detect the topography of the nanotube array ( Figure 4 ); immerse in 2mol / L NaOH for 48 hours until the aluminum oxide film is completely dissolved, then centrifugally wash with distilled water until the pH is neutral, and finally rinse twice with absolute ethanol, put it in a vacuum drying oven at room temperature and dry to constant weight, then Am...

Embodiment 3

[0032] Take a piece of purchased 200nm aluminum oxide film and place it in the middle of two quartz reaction cells. One quartz reaction cell is injected with a concentration of 0.05mol / L FeSO 4 Solution, inject 5g / L sodium borohydride aqueous solution into another quartz reaction tank, let it stand at room temperature for 12 minutes, remove the black nanotube / alumina composite film, and then wash the composite film with distilled water and absolute ethanol for 3-4 times , put into a vacuum drying oven at room temperature and dry to constant weight, partially dissolve with 2mol / L NaOH, and use a scanning electron microscope to detect the topography of the nanotube array ( Figure 5 ); immerse in 2mol / L NaOH for 48 hours until the aluminum oxide film is completely dissolved, then centrifugally wash with distilled water until the pH is neutral, and finally rinse twice with absolute ethanol, put it in a vacuum drying oven at room temperature and dry to constant weight, then Amorph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com