Sodium hypochlorite generator

A generator and acid tank technology, which is applied in the field of electrochemistry, can solve problems affecting the long-term safe operation of equipment, complex structure of tubular electrolytic tubes, and short operating cycle, so as to prolong continuous operating time, reduce pickling times, and reduce salt consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

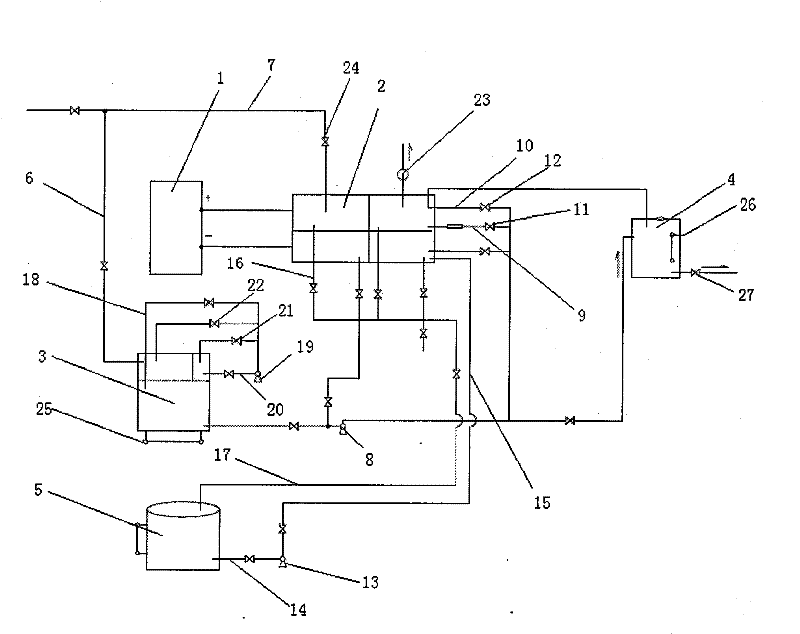

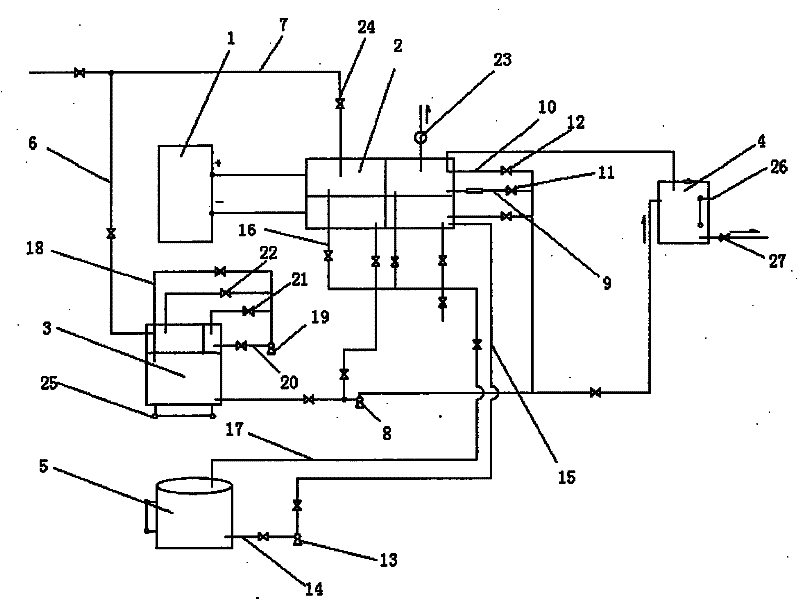

[0035] The present invention will be further described below in conjunction with the accompanying drawings.

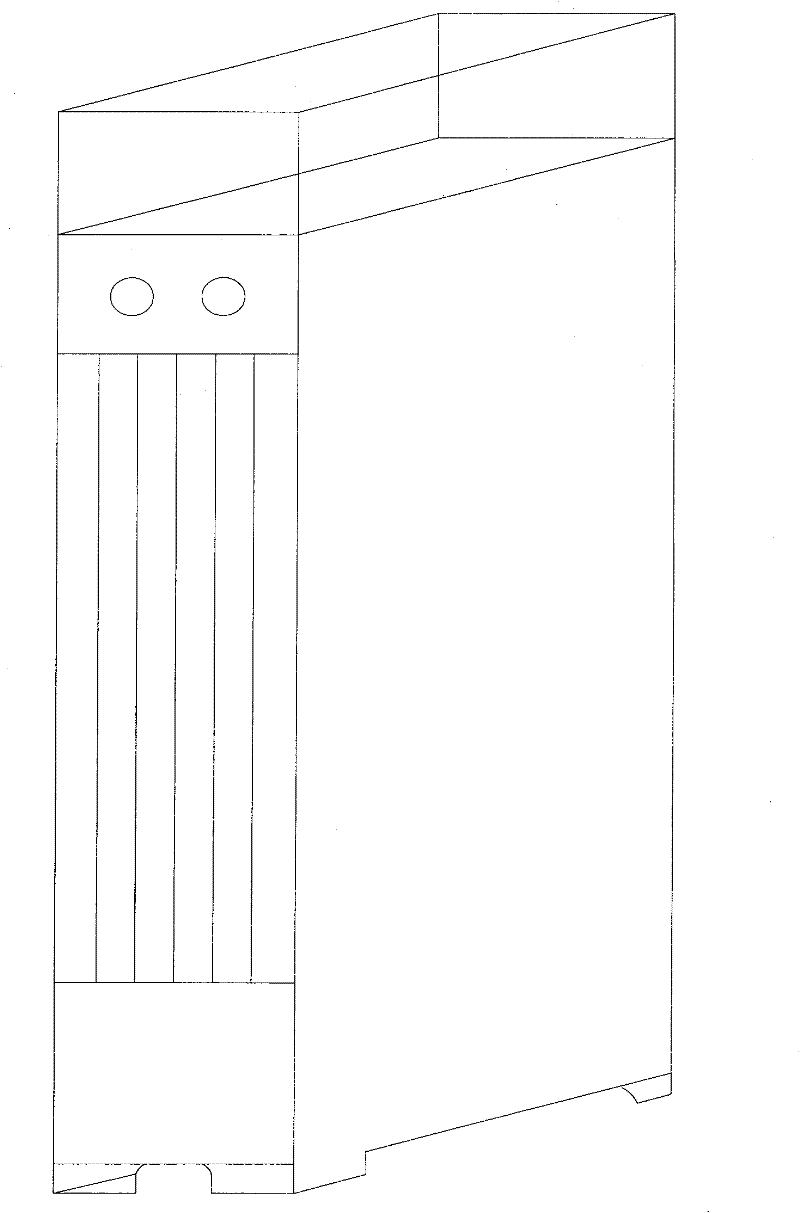

[0036] Such as figure 1 and figure 2 As shown, a NaClO generator includes an electric control cabinet 1, an electrolysis device 2, a salt dissolving device 3, a NaClO storage tank 4 and an acid tank 5.

[0037] The electric control cabinet 1 is electrically connected to the electrolysis device 2 , and a high-frequency switching power supply is arranged in the electric control cabinet 1 , and the high-frequency switching power supply is used to supply power to the electrolysis device 2 . The shell of the electrolysis device 2 is made of reinforced PVC material, and an electrolysis cell is arranged in the electrolysis device 2. The electrolysis unit in the electrolysis cell is composed of a plurality of compound electrodes. The material of the compound electrodes is a TA1 titanium plate, and the electrolyte in the electrolysis cell It flows in an "S" shape. The water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com