Composite flocculating agent and preparation method thereof

A composite flocculant, chitosan technology, applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve problems such as chemical bond linkage, and achieve the effect of simple operation, wide application range and wide pH value range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

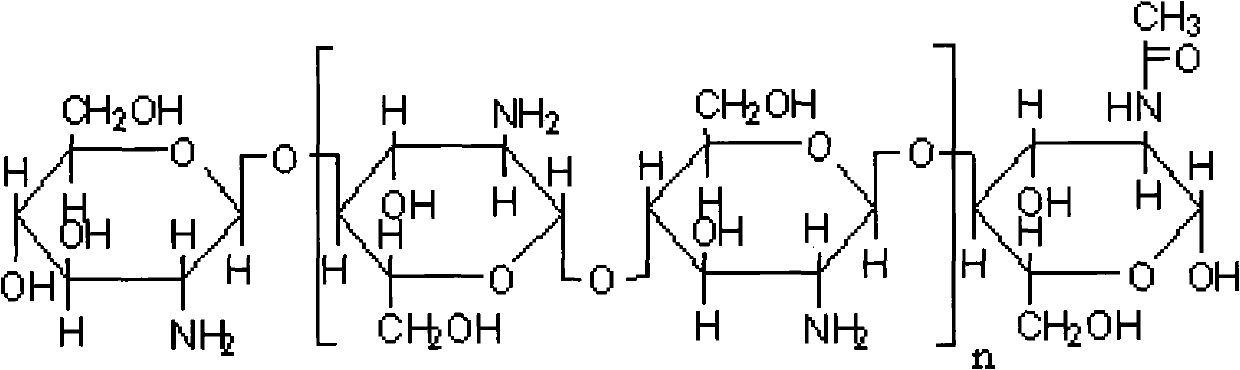

[0035] [embodiment 1]: chitosan is dissolved in 0.5% hydrochloric acid aqueous solution, is mixed with the solution of chitosan 2%, after the solution is uniform, adds cerium ammonium nitrate as initiator (add-on is chitosan unit mole number 3%), then add acrylamide (mass ratio to chitosan: 5:1), and react for 2 hours at 45°C to obtain the chitosan grafted polyacrylamide product; then add 100% of the original solution volume Isopropanol, and 20% of the volume of the original solution with a 40% NaOH aqueous solution by weight were reacted at 65°C for 3 hours to prepare a chitosan-hydrolyzed polyacrylamide composite flocculant. Through titration analysis, the content of carboxylic acid groups is 15%, and the content of polyacrylamide is 40% (by mass).

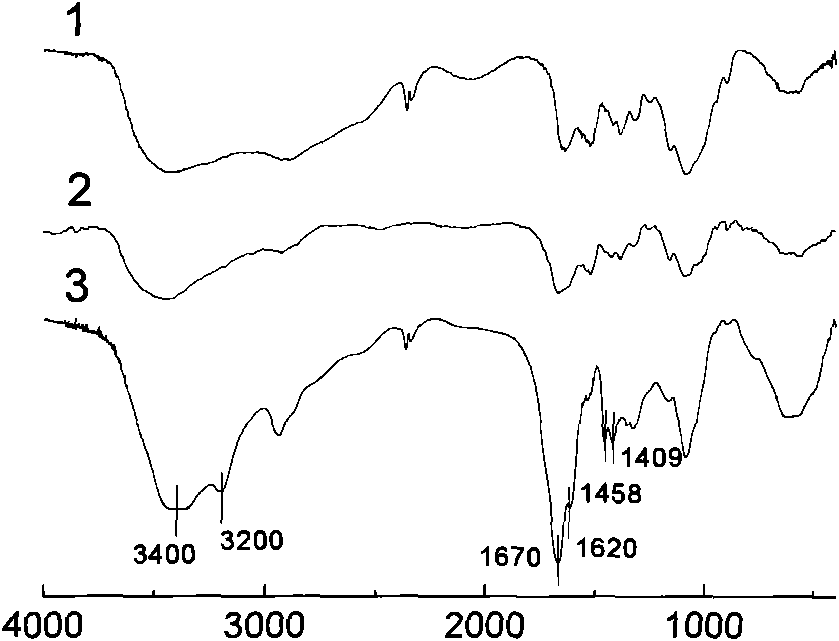

[0036] The infrared spectra of chitosan, chitosan-grafted polyacrylamide and chitosan-hydrolyzed polyacrylamide composite flocculant are shown in figure 1 ,from figure 1 see wavenumber 3400nm -1 , 3200nm -1 O-H, N-H characte...

Embodiment 2

[0038][embodiment 2]: chitosan is dissolved in 1.0% hydrochloric acid aqueous solution, is mixed with the solution of chitosan 3%, after the solution is uniform, adds cerium ammonium nitrate as initiator (add-on is chitosan unit mole number 2%), and acrylamide (mass ratio with chitosan: 5: 1), reacted for 2 hours at 45°C to obtain chitosan grafted polyacrylamide product; Alcohol, and 50% of the volume of the original solution with a 10% NaOH aqueous solution by weight were reacted at 85° C. for 4 hours to prepare a chitosan-hydrolyzed polyacrylamide composite flocculant. After analysis, the content of carboxylic acid groups is 10%, and the content of polyacrylamide is 30% (by mass). Its performance is similar to embodiment 1.

Embodiment 3

[0039] [embodiment 3]: chitosan is dissolved in 0.5% acetic acid aqueous solution, is mixed with the solution of chitosan 2%, after the solution is uniform, adds cerium ammonium nitrate as initiator (add-on is chitosan unit mole number 3%), and acrylamide (mass ratio with chitosan: 8: 1), reacted for 2 hours at 45°C to obtain chitosan grafted polyacrylamide; then add 200% isopropanol of the original solution volume , and 50% NaOH aqueous solution with a weight percentage concentration of 5% of the volume of the original solution, and reacted at 55° C. for 1 hour to prepare a chitosan-hydrolyzed polyacrylamide composite flocculant. After analysis, the carboxylic acid group content is 20%, and the polyacrylamide content is 45% (mass). Its performance is similar to embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com