Method for preparing levoglucosan from cellulose by catalytic pyrolysis

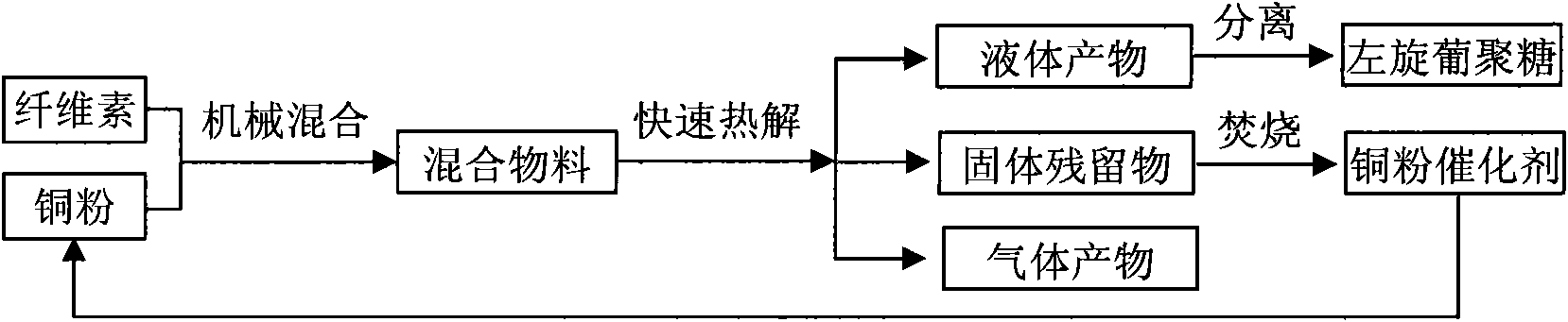

A technology for levo-glucan and catalytic pyrolysis, which is applied in the field of biomass energy utilization, can solve the problems of low yield of levo-glucan and high cost of separation and extraction, and achieves easy separation and extraction, high yield and high purity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Commercial microcrystalline cellulose is used as raw material, with an average particle size of 0.05mm, mixed with copper powder with a particle size of 0.5mm, the mixing ratio of the two is 2:1, and then the mixed material is pyrolyzed at 420°C under a nitrogen atmosphere In 10 seconds, the yield of the liquid product was 76%, and the levoglucosan content was analyzed by gas chromatography, and the yield of levoglucosan was calculated to be 46%.

Embodiment 2

[0023] Using commercial microcrystalline cellulose as raw material, the average particle size is 0.05mm, mixed with brass powder with a particle size of 0.5mm, the mixing ratio of the two is 1:2, and then the mixed material is heated at 400 ° C under an inert gas atmosphere ( With the combustible gas produced by pyrolysis as protective gas) under pyrolysis for 10s, the yield of liquid product obtained was 80%, and the content of levoglucosan was analyzed by gas chromatography, and the yield of levoglucosan was calculated to be 56%. %.

Embodiment 3

[0025] Commercial α-cellulose is used as raw material with an average particle size of 0.19mm, mixed with brass powder with a particle size of 1.0mm, the mixing ratio of the two is 1:2, and then the mixed material is heated at 380°C under an inert gas atmosphere ( With the combustible gas produced by pyrolysis as protective gas) under pyrolysis for 10s, the yield of liquid product obtained was 74%, and the content of levoglucosan was analyzed by gas chromatography, and the yield of levoglucosan was calculated to be 50%. %.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com