Homogeneous furnace for toughened glass

A tempered glass and homogeneous furnace technology, applied in glass production, etc., can solve the problems of low processing efficiency and high energy consumption, and achieve the effects of improving production efficiency, ensuring product quality, and eliminating heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

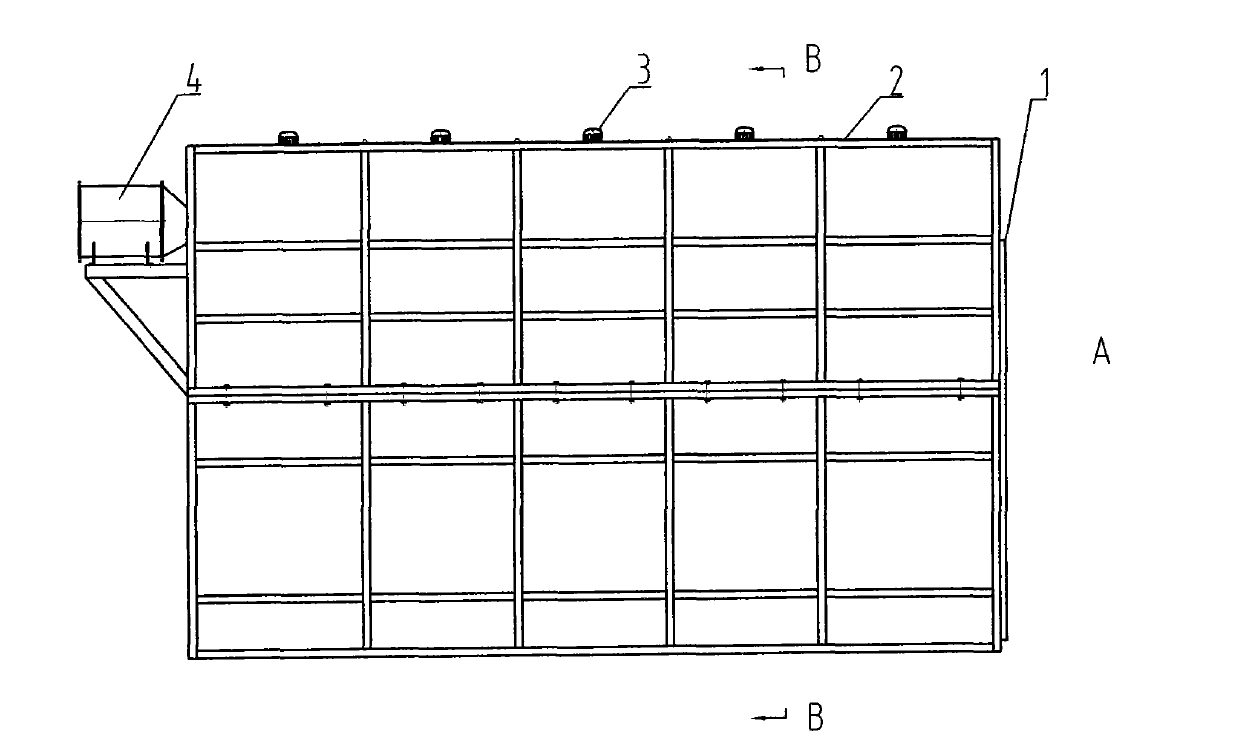

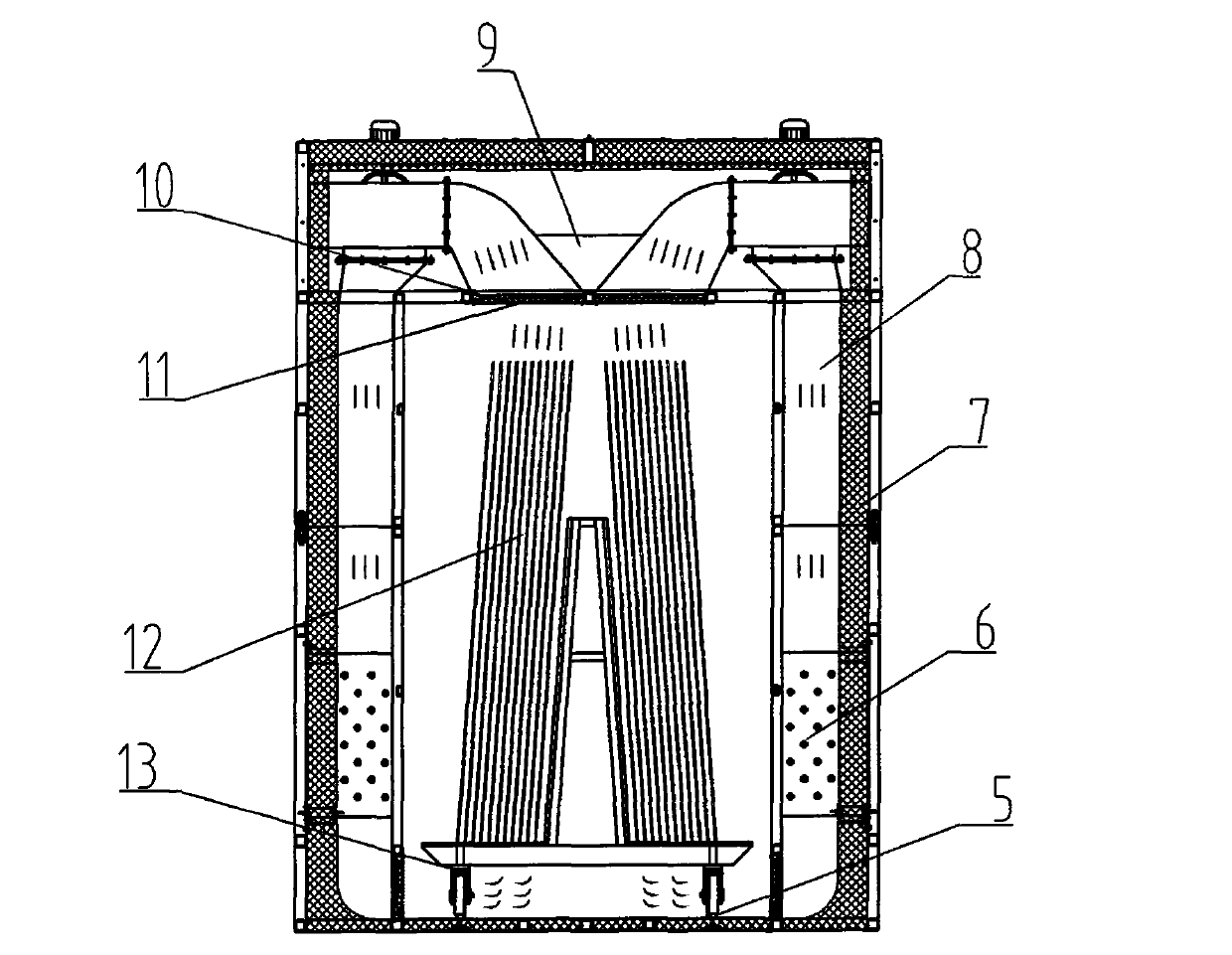

[0021] The present invention comprises a furnace body 2, a furnace door 1 and an air cooler 4 respectively arranged at both ends of the furnace body 2, an insulation layer 7 is arranged in the periphery of the furnace body 2, and a thermal insulation layer 7 is arranged on both sides and the top of the furnace body 2. Circulating air duct 8, the bottom and top of heat circulating air duct 8 are respectively provided with heater 6 and circulating fan 3, and cooling circulating air duct 9 is arranged between the top heat circulating air duct 8 of furnace body 2.

[0022] The ventilation holes 10 of the top heat circulation air duct 8 and the cooling circulation air duct 9 are arranged on the top guide plate 11 of the furnace body 2 .

[0023] The present invention can adopt electrical automatic control, which is a general technology realized by ordinary technicians in the same industry, and will not be described in detail here.

[0024] A course of action of the present inventio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com