Method for processing horizontal type jack wallboard

A processing method and jack technology, applied in the direction of lifting device, can solve the problems of long processing time, waste of auxiliary materials, cumbersome processing, etc., and achieve the effect of shortening processing time, improving processing efficiency, and reducing processing steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

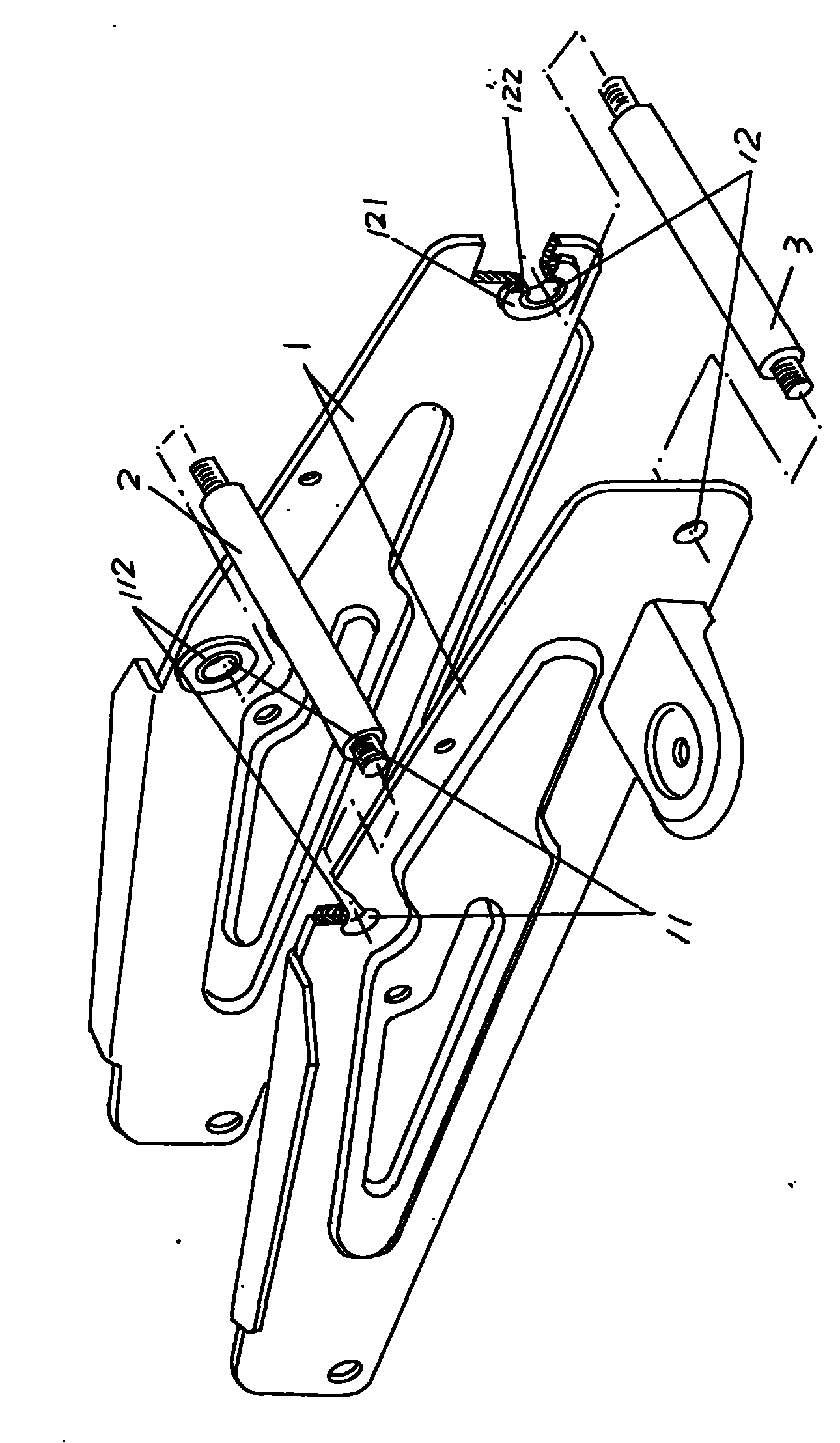

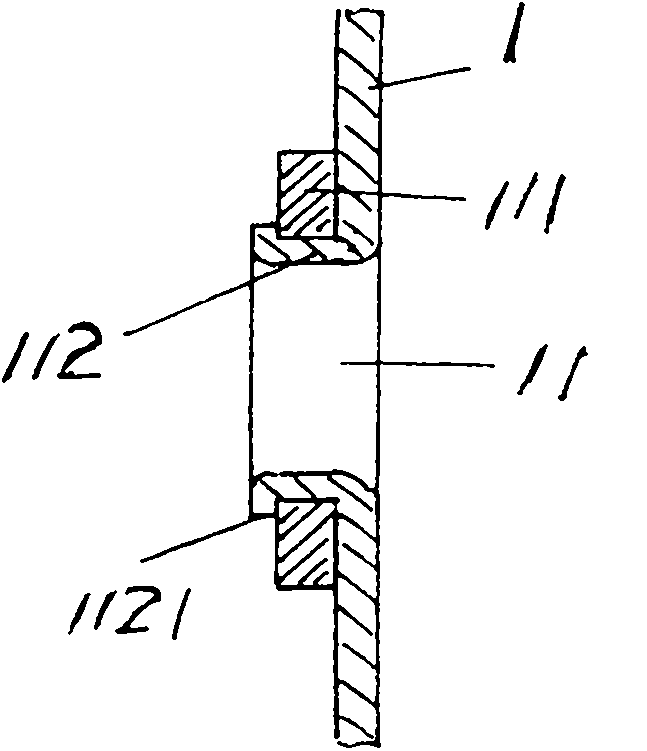

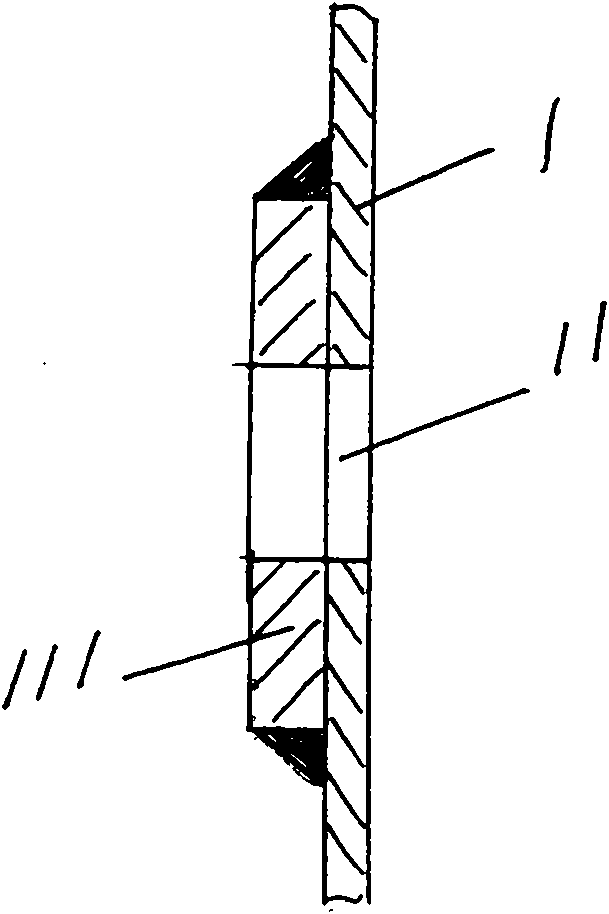

[0012] please see figure 1 , this embodiment 1 is embodied in this way, when the wallboard is formed by the stamping device through the mold, the upper arm shaft hole 11 for setting the upper arm shaft 2 and the oil cylinder for setting the oil cylinder shaft 3 are punched out on the wallboard 1 at the same time shaft hole 12, and at the same time make the material at the upper arm shaft hole 11 and the oil cylinder shaft hole 12 extend towards the back of the wallboard 1 (that is, the side facing the other wallboard 1) to form a structure that helps to strengthen the upper arm shaft hole 11 and the strength of the cylinder shaft hole 12, the upper arm shaft hole stack ring 112 and the oil cylinder shaft hole stack ring 122, and then, an upper arm shaft hole reinforcement washer 111 is tightened outside the upper arm shaft hole stack ring 112 and the oil cylinder shaft hole stack ring 122 is tightened Cover an oil cylinder shaft hole reinforcement washer 121. It can be seen ...

Embodiment 2

[0014] please see figure 2 and combine figure 1 , since the cylinder shaft hole 12 is formed in exactly the same way as the upper arm shaft hole 11, so in figure 1 Only the upper arm shaft hole 11 is shown in the figure. When the wallboard 1 is molded by the punching device, the upper arm shaft hole 11 for setting the upper arm shaft 2 and the oil cylinder shaft hole 12 for setting the oil cylinder shaft 3 are punched out on the wallboard 1 simultaneously, and the upper arm shaft hole is made simultaneously. 11 and the material at the cylinder shaft hole 12 extend toward the back of the wallboard 1 (that is, the side facing the other wallboard 1) to form an upper arm shaft that helps to strengthen the strength of the upper arm shaft hole 11 and the cylinder shaft hole 12. Hole stack ring 112 and oil cylinder shaft hole stack ring 122, and then, an upper arm shaft hole reinforcement washer 111 is tightly sleeved outside the upper arm shaft hole stack ring 112 and an oil cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com