Machine capable of removing solid residue from bucket

A technology of solid residue and barrel removal machine, which is applied in the directions of transportation and packaging, loading/unloading, etc., can solve the problems of producing toxic and harmful gases, harsh production environment, etc., and achieves the effects of low labor intensity, good wear resistance and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

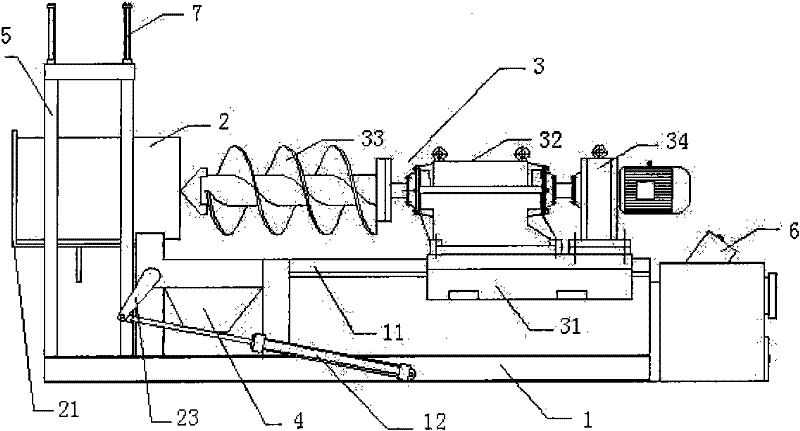

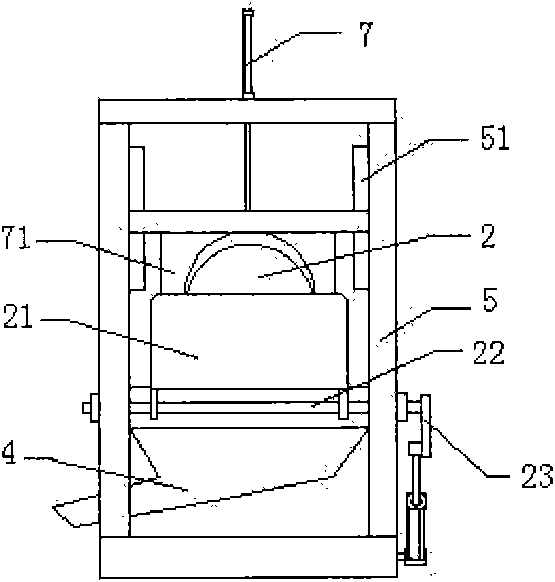

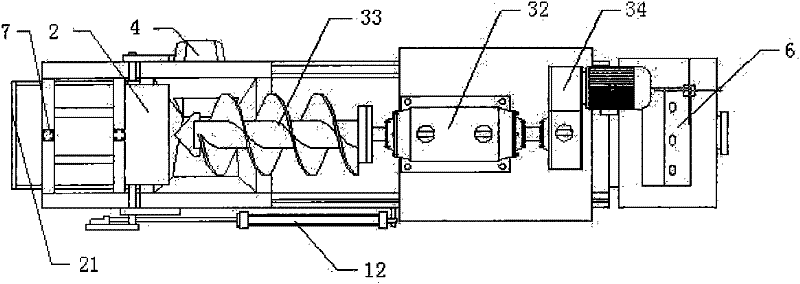

[0015] The solid residue debarrel machine of the present invention will be further described below in conjunction with the accompanying drawings of the description.

[0016] see figure 1 , figure 2 and image 3 , a solid residue debarrel machine according to the present invention, comprising a bottom frame 1, a bucket 2 placed above the bottom frame 1, and a drill drive device 3, inside the bottom frame 1 and below the drill drive device 3 there is an outlet Hopper 4, a fixed gantry 5 is fixed on one side of the bottom frame 1, an electric control operation platform 6 is arranged on the other side of the bottom frame 1, the material bucket 2 is horizontally placed in the fixed gantry 5, and the top of the fixed gantry 5 A hydraulic fixing device 7 for fixing the material barrel 2 is provided, a mechanical slider guide rail 11 is arranged on the underframe 1, and the drill bit driving device 3 includes a mechanical slider 31 matched with the mechanical slider guide rail 11, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com