Upper neck casting mold of integrated cast steel supporting roll

A back-up roll and cast steel technology, applied in the direction of casting mold, casting mold composition, casting molding equipment, etc., to achieve the effect of reducing resistance, ensuring axial shrinkage, and less joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

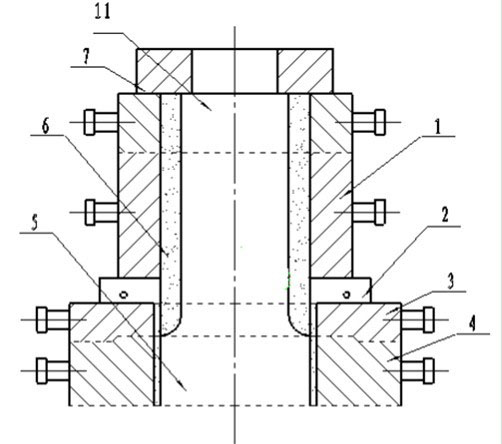

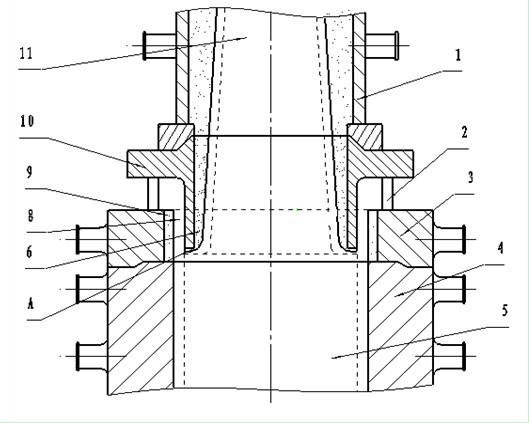

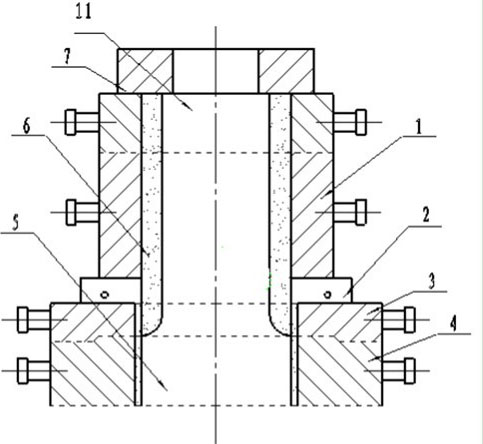

[0014] Example: see figure 2 , the upper neck mold of the integral cast steel back-up roll of the present invention has an adjacent combined upper neck integral metal mold 1, which can draw out the slide block 2, and consists of roll body metal molds 3 and 4, and the upper neck metal mold top is cast according to the casting The size of the steel backup roll has a casting amount of 30-50wt% counterweight briquetting block 7 . Mold making first hangs sand on the inner wall of the metal mold of the roller body and the metal mold of the upper neck to make a mold, wherein the sand mold 6 of the upper neck extends down into the mold cavity of the roller body, then the mold is assembled, and the slide block 2 is placed at the same time. After the casting and filling casting is completed, the slider 2 is radially drawn out, and under the joint action of the counterweight briquetting block 7 and the upper neck casting metal mold 1, the upper neck sand mold 6 hardened by high temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com