Tube expanding method and tube expanding device for expanding connection of multiple tubes and tube plates

A tube expansion device and tube technology, which is applied in the field of shell-and-tube/tube-fin heat exchangers and machinery, can solve the problems of long labor hours, high manufacturing labor cost, long occupation time, etc., and achieves low dimensional accuracy requirements and production. The effect of high efficiency and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

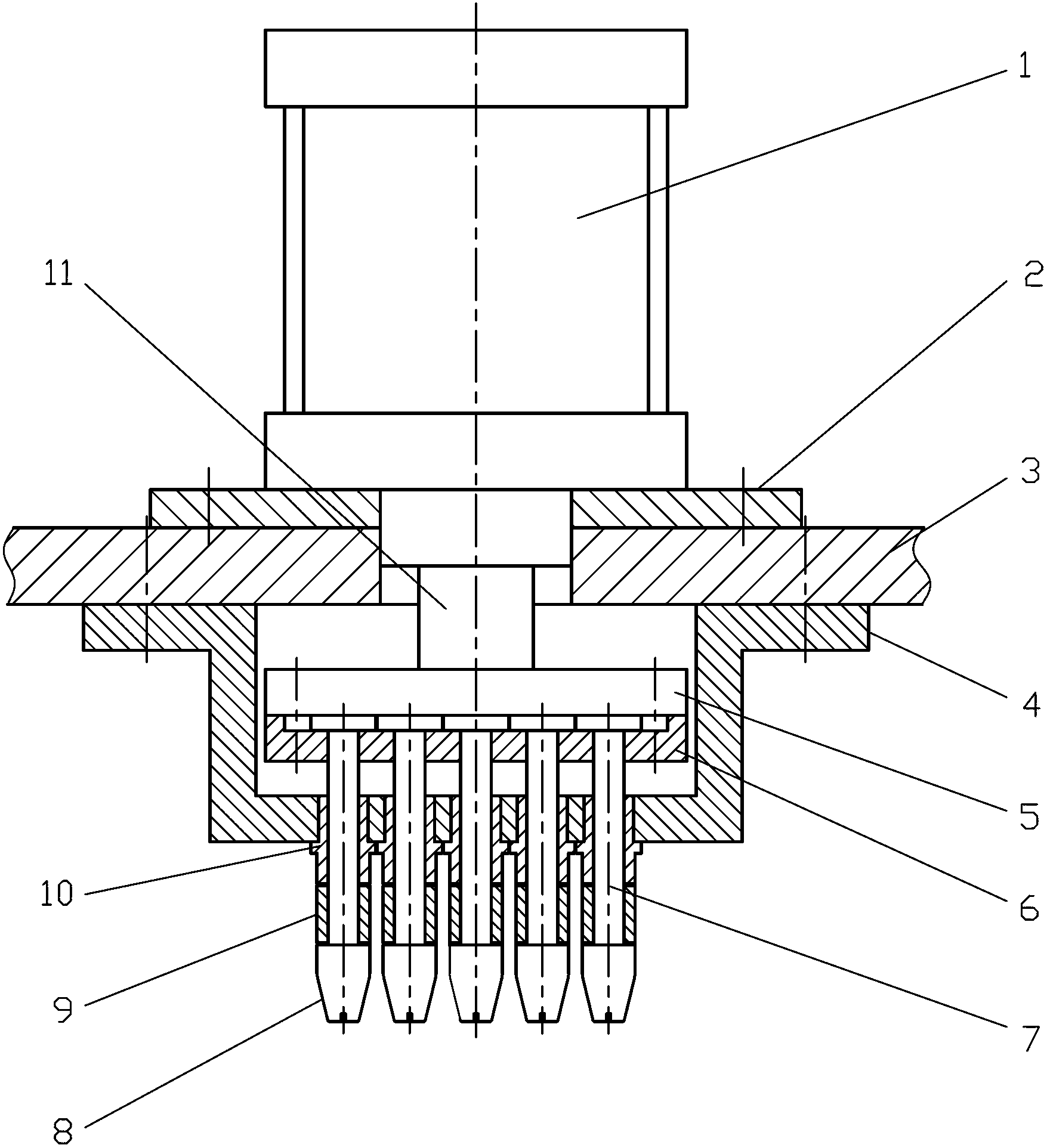

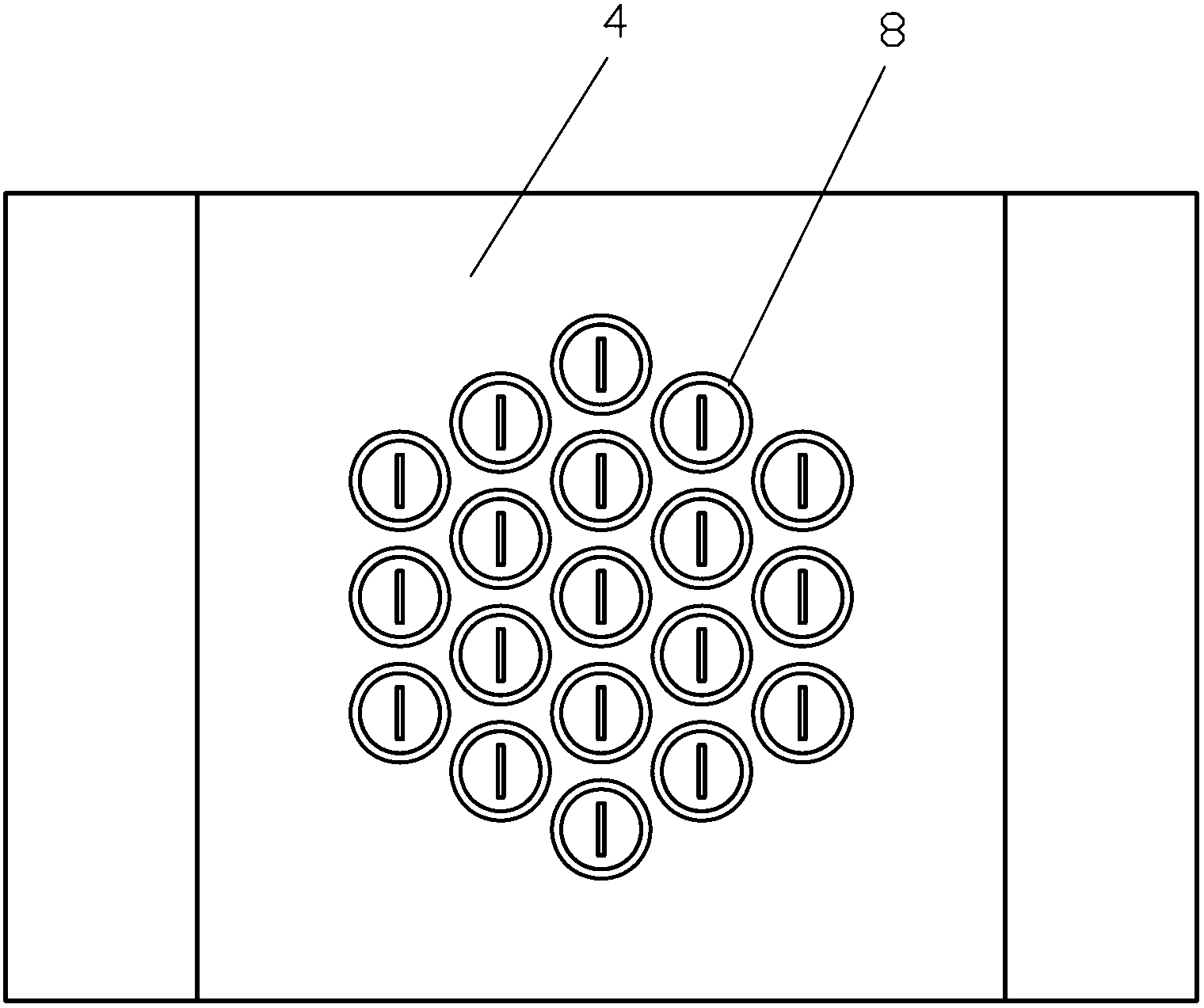

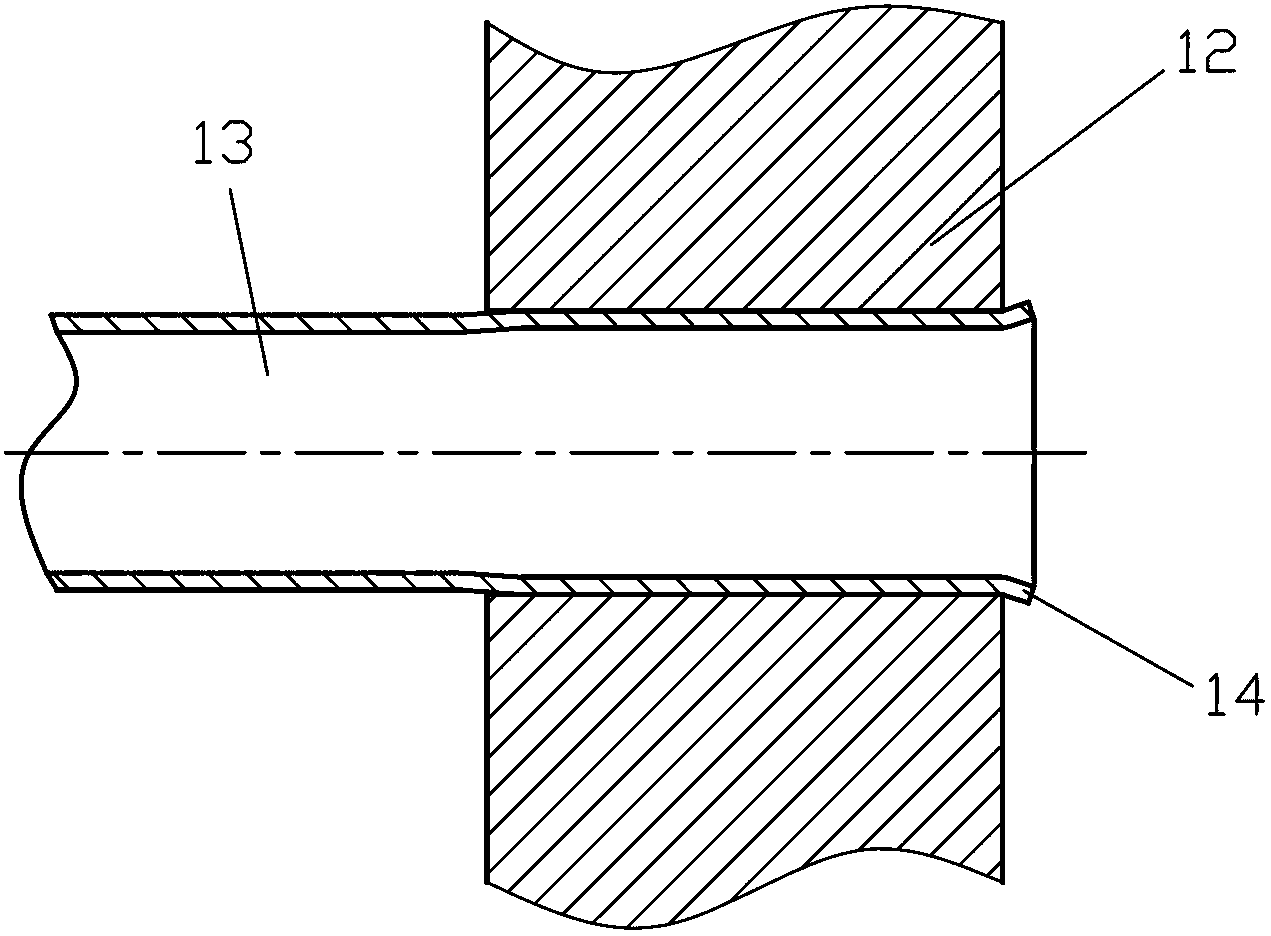

[0017] refer to figure 1 and figure 2 , a tube expansion device of the present invention, including an expansion head tie rod seat 6, an expansion joint seat 4, an expansion head assembly, a fixed plate 3 and a hydraulic cylinder connecting plate 5, and the expansion head assembly includes a plurality of expansion head tie rods 7, The upper end of the expansion head rod 7 is set on the expansion head rod seat 6, and each expansion head rod 7 is sequentially set with an expansion rod bushing 10, an elastic expansion sleeve 9 and a guide nut 8; The bushing 10 is fixed in the bottom through hole of the expansion joint seat 4, and the upper part of the expansion joint seat 4 is connected to the cylinder block 1 of the hydraulic cylinder through the fixed plate 3; the expansion head tie rod seat 6 is passed through The hydraulic cylinder connecting plate 5 is connected to the hydraulic cylinder tie rod 11 .

[0018] The present invention carries out tube expansion according to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com