System for ultrasonically detecting defects in a pipe wall

A technology for detecting tubes and tube walls, which can be used in the analysis of solids using sonic/ultrasonic/infrasonic waves, fluids using vibration, and material analysis using sonic/ultrasonic/infrasonic waves, which can solve problems such as unreliable imaging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

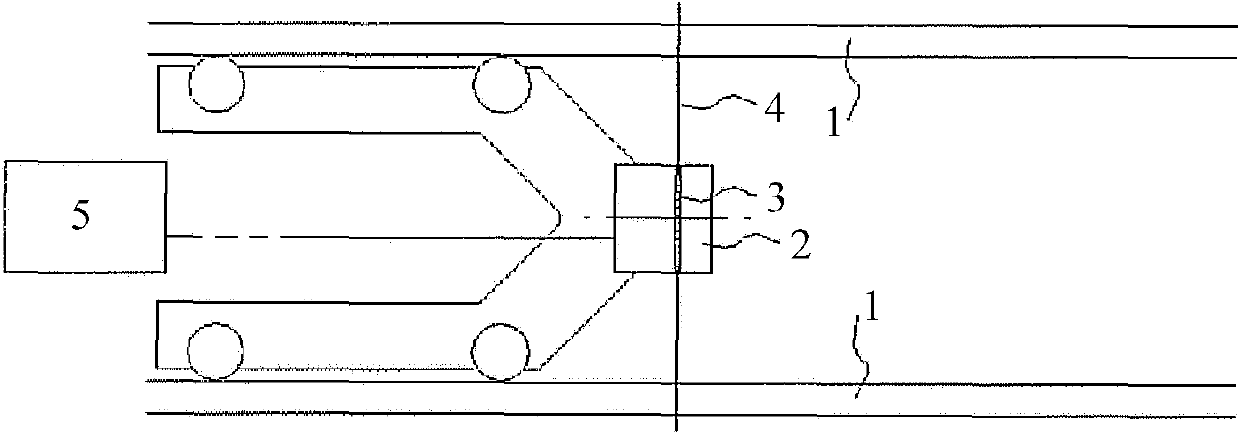

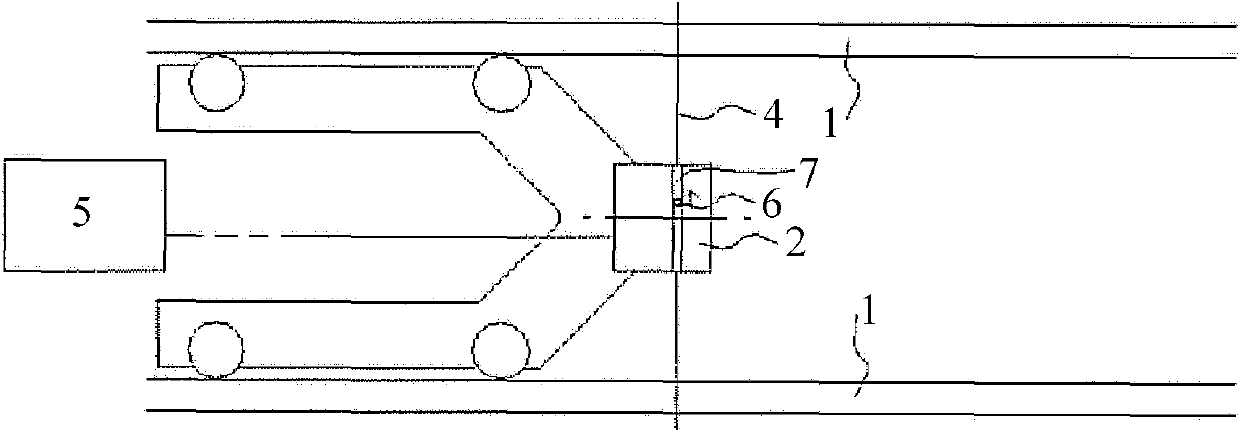

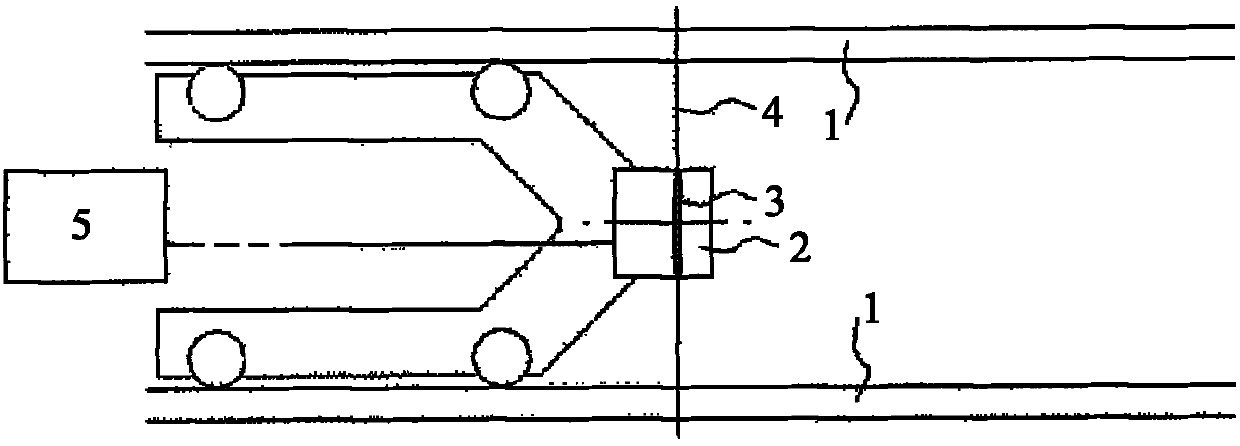

[0037] figure 1 A schematic embodiment of a system for detecting defects in a pipe wall 1 is shown, the system comprising an ultrasonic transmitter 2 arranged to emit ultrasonic signals from the inside of the pipe towards the pipe wall 1 via an emission opening , and receive the backscattered signal from the wall 1 of the tube via the entry opening. In this exemplary embodiment, the transmitter comprises an array of substantially circular ultrasonic transducers 3 arranged to emit and receive a plurality of ultrasonic waves having different main directions in a plane 4 substantially perpendicular to the axis of the pipe. Signal. The transmitters 3 are connected to a control module 5 arranged to energize the transmitters 3 to cause the transmitters to emit their signals (ie signal pulses). These signal pulses can be transmitted simultaneously or sequentially or mixed. The backscattered signal pulses can be received by the same transmitter in the time slots (reception slots) b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com