Production method of multi-layer printed circuit board and multi-layer printed circuit board

A technology for printed circuit boards and production methods, applied in the production of multilayer printed circuit boards, in the field of multilayer printed circuit boards, can solve the problems of interlayer sliding boards and uneven thickness, and achieve low cost, high efficiency, and low cost. The effect of polluting emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

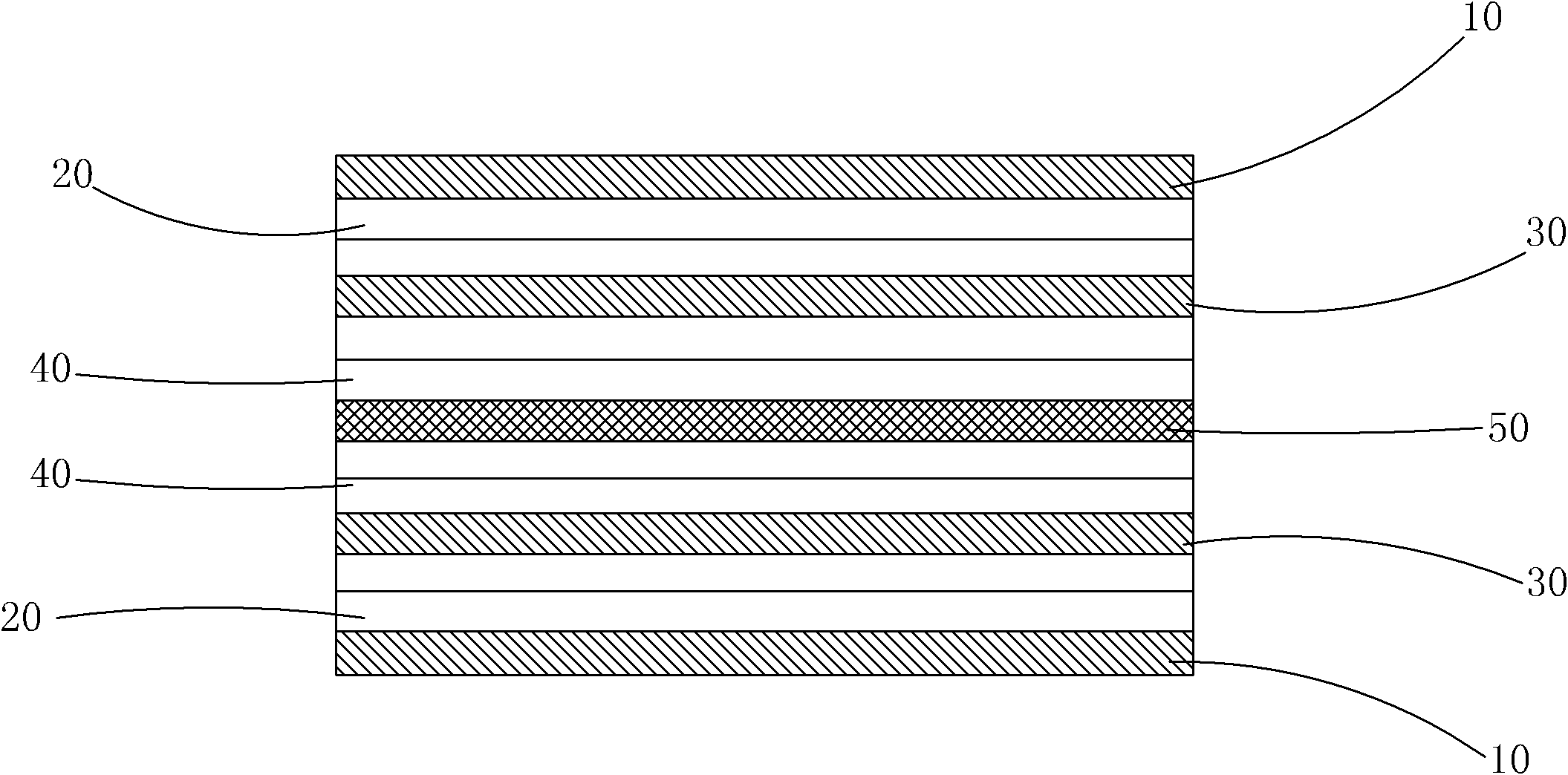

[0029] Use FR-4 insulating light board 0.40 0 / 0 to roughen the surface after polishing, and laminate with 7628 prepreg, core board and outer layer copper to form a six-layer printed circuit board, according to the resin type of the six-layer printed circuit board Laminate under the required curing conditions, and conduct reliability tests such as thermal stress, PCT (soldering resistance), high temperature and high humidity, etc. on the laminated six-layer printed circuit board. The test results are shown in Table 1-3 respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com