Charging optimization manager of lead-acid storage battery

A lead-acid battery and manager technology, applied in the direction of secondary battery charging/discharging, battery circuit devices, collectors, etc., can solve the problems of increased differentiation distance, damage, overcharging, etc., to prevent vulcanization and easy to use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

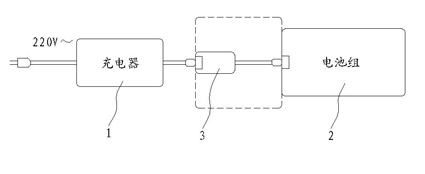

[0070] refer to figure 1 As shown, in the existing technology, the three-stage charger 1 is directly connected in series with the lead-acid battery pack 2 to be charged.

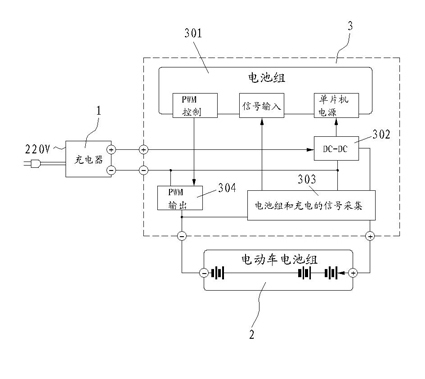

[0071] refer to figure 2 The improvement of the present invention lies in that the charging optimization manager 3 of the present invention is connected in series between the original three-stage charger 1 and the lead-acid battery pack 2 . The charging optimization manager 3 monitors and collects the terminal voltage signal of the lead-acid battery pack and the charging current signal of the charging circuit through the controller, and controls an extra voltage to be superimposed on the charging circuit or turns on or off the superimposed extra voltage in a PWM manner. Voltage charging circuit.

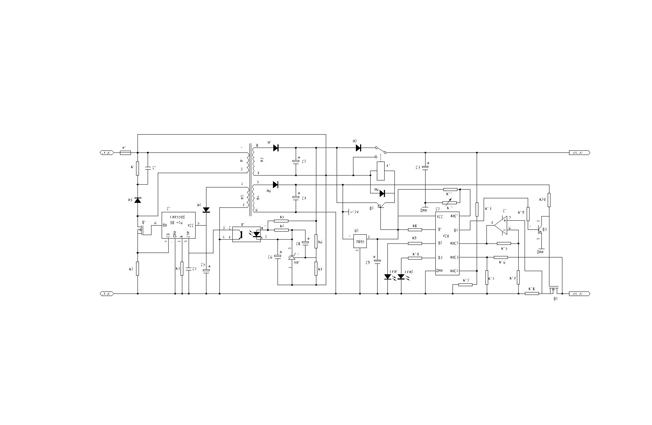

[0072] specific reference image 3 and Figure 4 As shown, the charging optimi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com