Fluorinion-doped zinc oxide porous prism array film, and preparation and application thereof

A fluoride ion and prism technology is applied in the field of zinc oxide porous prism array film and its preparation and application. The effect of large-scale industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1. Prepare Zn(NO 3 ) 2 and NH 4 F mixed solution 1L, Zn(NO 3 ) 2 Molar concentration is 0.05M, NH 4The molar concentration of F is 0.2M. After stirring for half an hour, take 60ml of the prepared solution and pour it into a 100ml beaker. After suspending the conductive glass substrate, react for 1 hour under the condition of a chemical bath at 70°C. Take out the conductive glass substrate and use a deionized After rinsing with water, it was found that a dense, uniform transparent film had formed on the substrate. Dry the above film product and move it into a muffle furnace, sinter at 500°C for 1 hour, and operate at a rate of heating and cooling not exceeding 3°C / min to obtain a ZnO-F prismatic array film with a porous hierarchical structure.

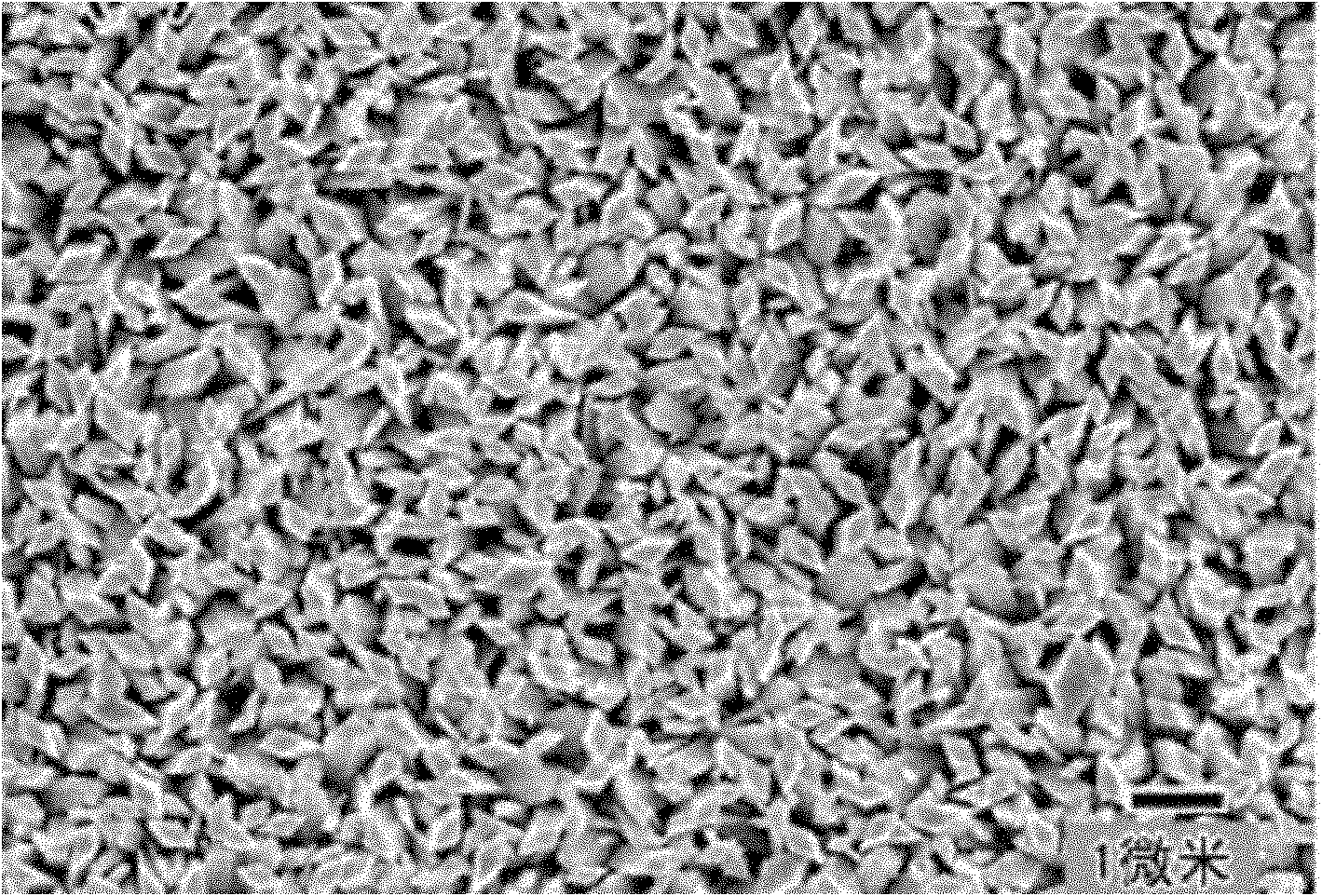

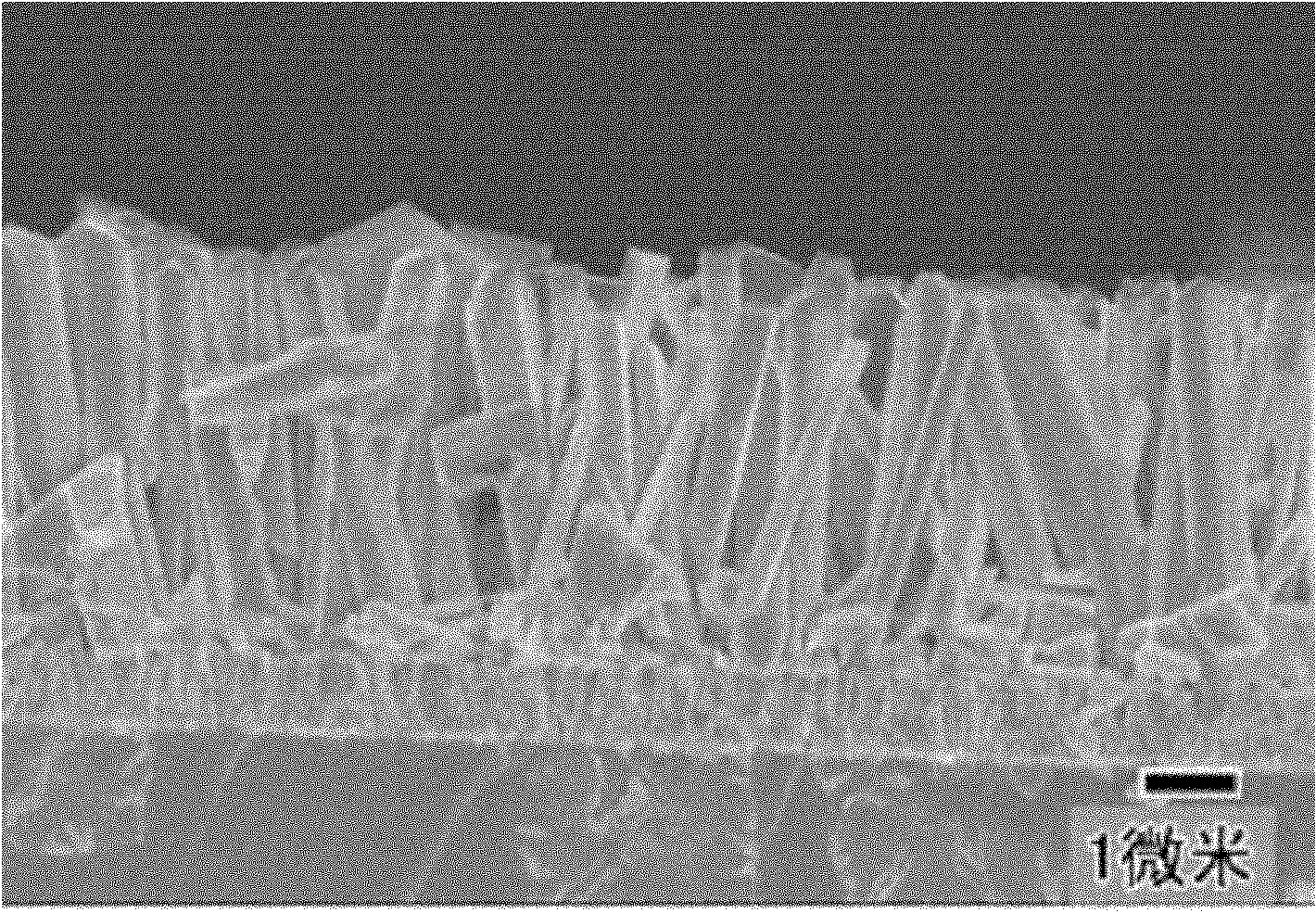

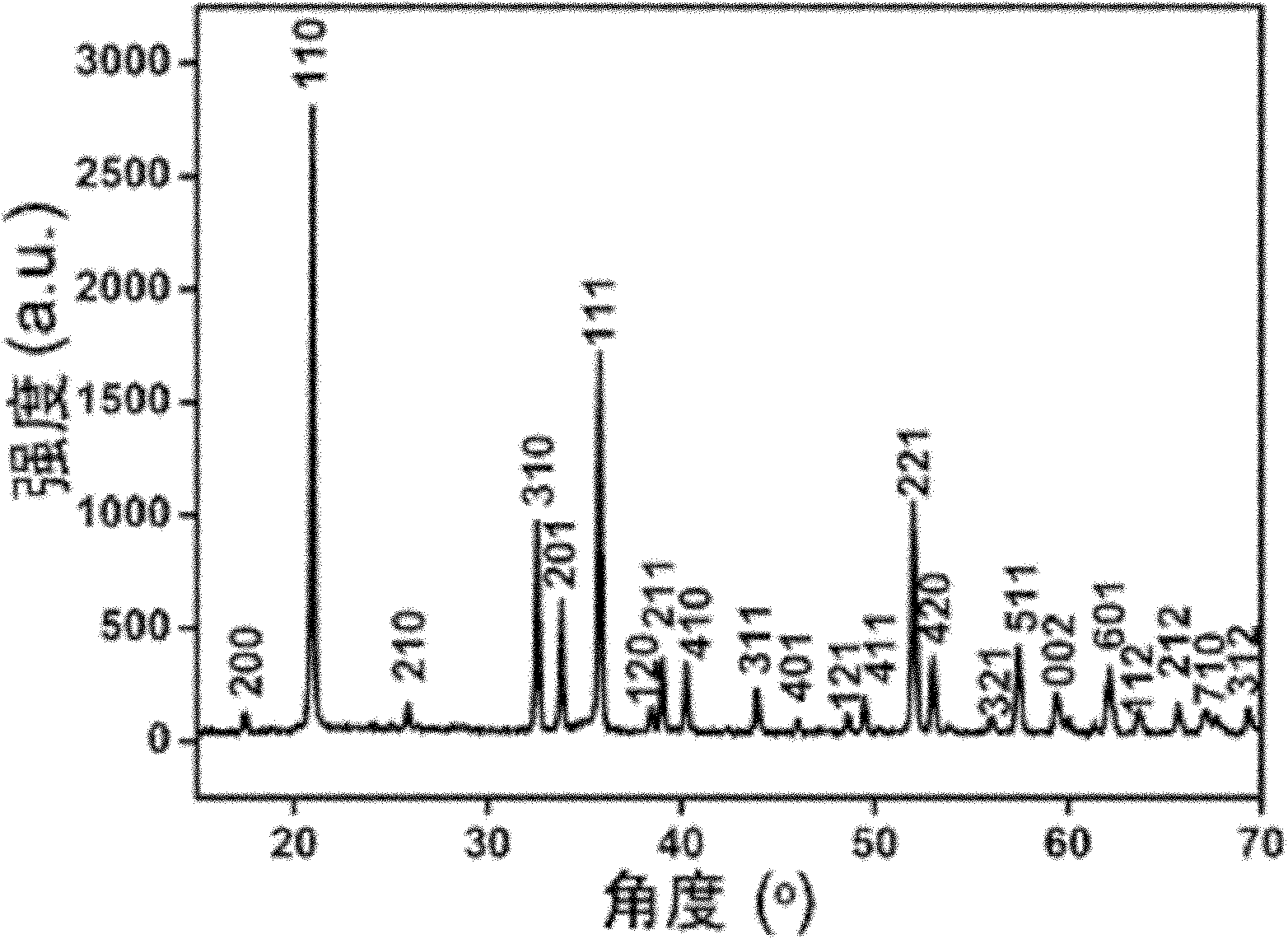

[0035] Analytical tests showed (see attached figure) that the films obtained after the chemical bath reaction consisted of arrays of prisms with diameters ranging from 400 nm to 1 μm ( figure 1 , SEM picture), the length is...

Embodiment 2

[0038] A dense layer composed of small zinc oxide particles with a particle size of about 15 nanometers is pulled on the conductive glass substrate in advance. Formulated with Zn(NO 3 ) 2 and NH 4 F mixed solution 1L, Zn(NO 3 ) 2 Molar concentration is 0.05M, NH 4 The molar concentration of F is 0.2M. After stirring for half an hour, take 60ml of the prepared solution and pour it into a 100ml beaker. After suspending the conductive glass substrate with zinc oxide particles, react for 1 hour under the condition of a chemical bath at 70°C, and take out the substrate. , rinsed with deionized water, and found that a dense, uniform transparent film was formed on the substrate. Dry the above film product and move it into a muffle furnace, sinter at 500°C for 1 hour, and operate at a rate of heating and cooling not exceeding 3°C / min to obtain a ZnO-F prismatic array film with a porous hierarchical structure.

[0039] After 1 hour of chemical bath reaction, Zn(OH)F prisms with m...

Embodiment 3

[0041] Formulated with Zn(NO 3 ) 2 and NH 4 F mixed solution 1L, Zn(NO 3 ) 2 Molar concentration is 0.05M, NH 4 The molar concentration of F is 0.2M. After stirring for half an hour, take 60ml of the prepared solution and pour it into a 100ml beaker. After suspending the conductive glass substrate, react for 1 hour under the condition of a chemical bath at 85°C, take out the conductive glass substrate, and use a deionized After rinsing with water, it was found that a dense, uniform transparent film had formed on the substrate. Dry the above film product and move it into a muffle furnace, sinter at 500°C for 1 hour, and operate at a rate of heating and cooling not exceeding 3°C / min to obtain a ZnO-F prismatic array film with a porous hierarchical structure. The product is a diameter Very large, without obvious prism boundary structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com