Replicate system of automobile engine steel grade

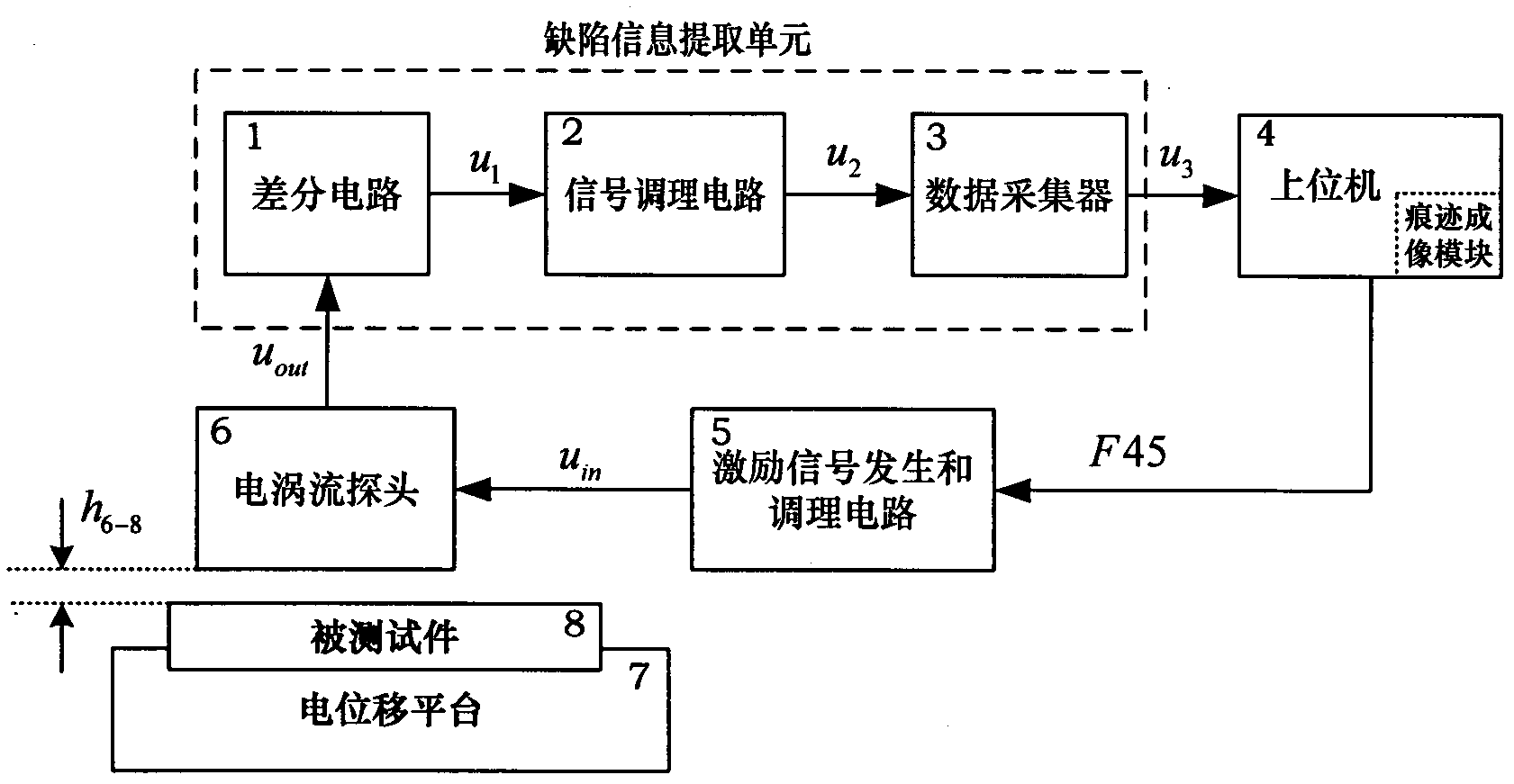

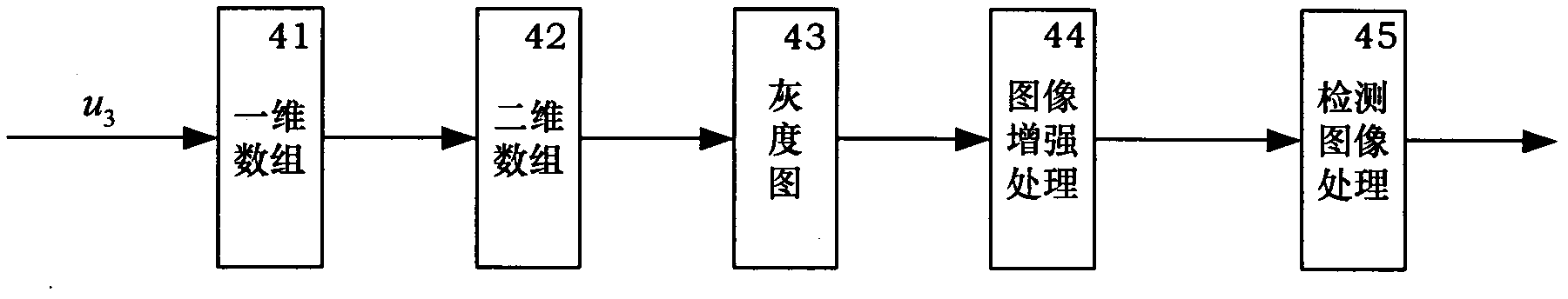

A technology for automobile engines and steel grades, which is applied in image data processing, instruments, calculations, etc. It can solve problems such as defect equivalent information and unobvious signals that have not yet developed to the imaging stage, so as to reduce electromagnetic interference, increase detection signals, The effect of reducing the error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0095] Example: Using the reproduction system provided by the present invention to reproduce the engine steel grade of a certain type of automobile, Figure 5 It is the existing steel grade on the engine, and no difference can be seen from the naked eye, but after scanning by the reproduction system of the present invention, it is found that the numbers "0" and "5" are abnormal, and the result shows the number "0" "Is formed by re-polishing the number "9" and pressing, and the number "5" is formed by re-polishing the number "4" and pressing, such as Figure 5A , Figure 5B Shown.

PUM

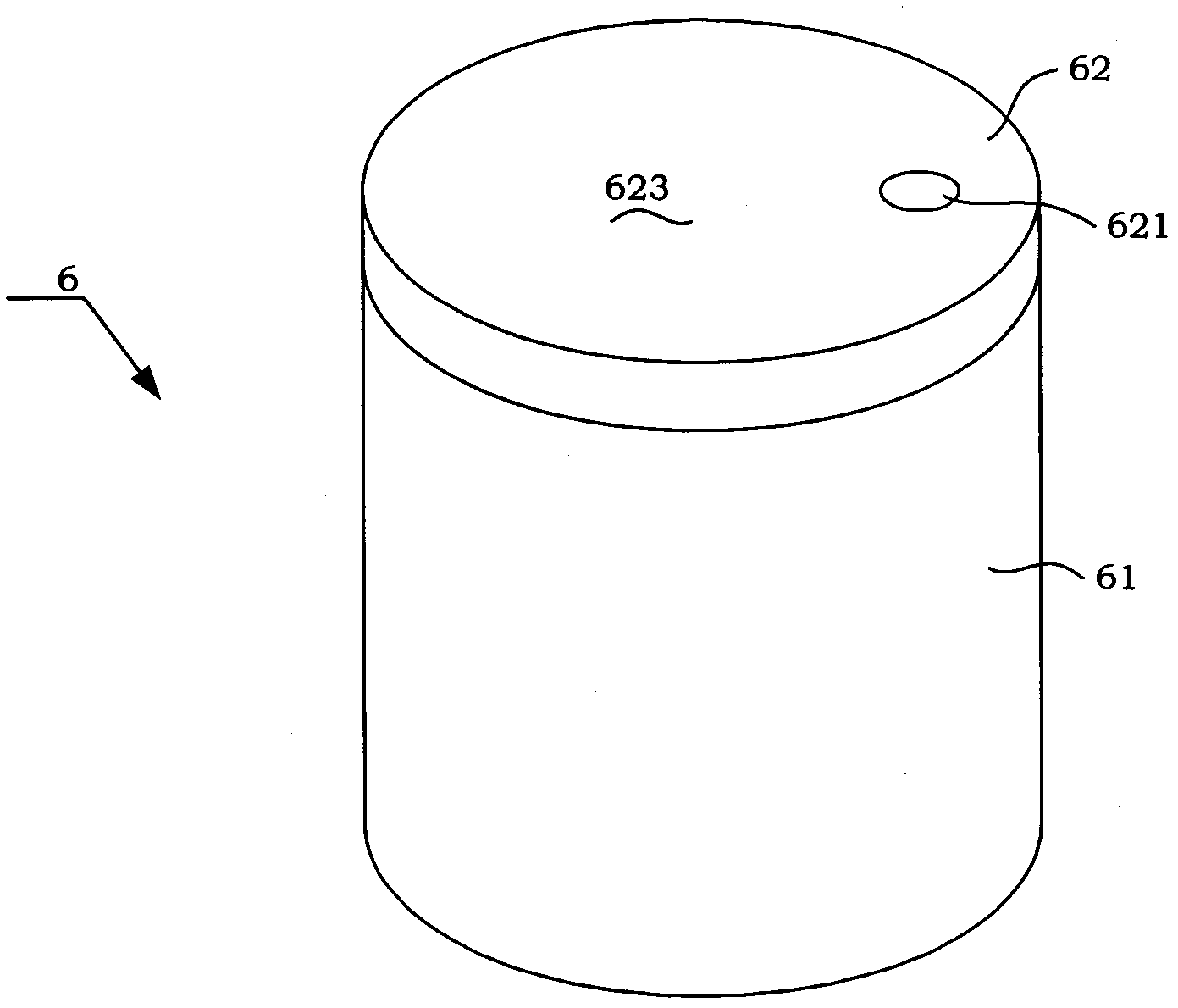

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com