Vacuum phase-transition heat transfer solar flat-plate heat-collecting system and working medium used for same

A technology of solar flat panels and flat panel heat collectors, applied in the field of solar energy utilization, can solve problems such as difficult promotion, high cost of heat pipe type solar flat panel heat collectors, inability to separate installation, etc. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

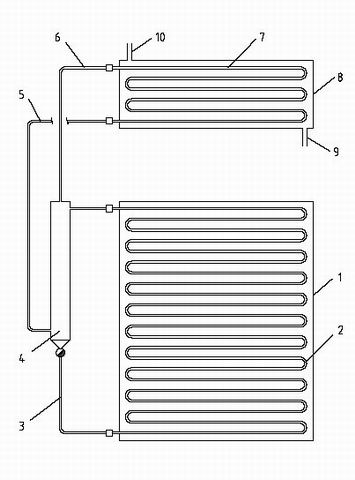

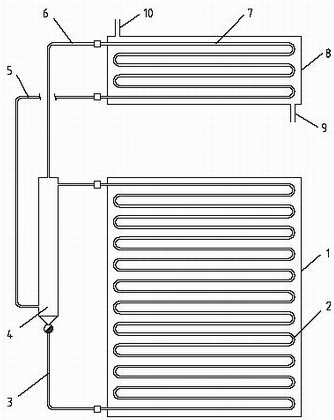

[0023] see figure 1 As shown, the vacuum phase change heat transfer type solar panel heat collection system of this embodiment includes a plate collector frame 1 , a gas-liquid separator 4 , a heat accumulator 8 , a vacuum evaporator 2 , and a condenser 7 . The vacuum evaporator 2 is placed inside the flat plate collector frame 1 and penetrates the flat plate heat collector frame 1 to form two connection ends; the condenser 7 is placed inside the heat accumulator 8 and penetrates the heat accumulator 8 to form two connections end. One end of the vacuum evaporator 2 is connected to the gas-liquid separator 4, the gas outlet of the gas-liquid separator 4 is connected to one end of the condenser 7 through the vapor rising pipe 6, and the liquid outlet of the liquid separator 4 is connected to the liquid supply pipe 3 of the evaporator It is connected with the other end of the vacuum evaporator 2, and the other end of the condenser 7 is connected with the gas-liquid separator 4 t...

Embodiment 2

[0029] A working fluid specially used in the vacuum phase change heat transfer type solar panel heat collection system described in Example 1, the working fluid is a multi-component composite working fluid.

[0030] The multi-component composite working medium is one or several kinds of liquid-gas phase change substances.

[0031] The liquid-gas phase change substance is one or more of water, acetone, chloroform, methanol, and ethanol.

example 1

[0032] Example 1, water is used as the working fluid, the vacuum degree is 85.59kPa, and the evaporation temperature of the working fluid after the system is installed is 55°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com