Aluminum matrix composite material with ultra-low friction coefficient and preparation method thereof

An ultra-low friction, aluminum-based material technology, applied in anodizing and other directions, can solve the problems of complex process, high preparation cost, low friction and wear performance, etc., and achieve the effect of simple process, low cost and easy repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

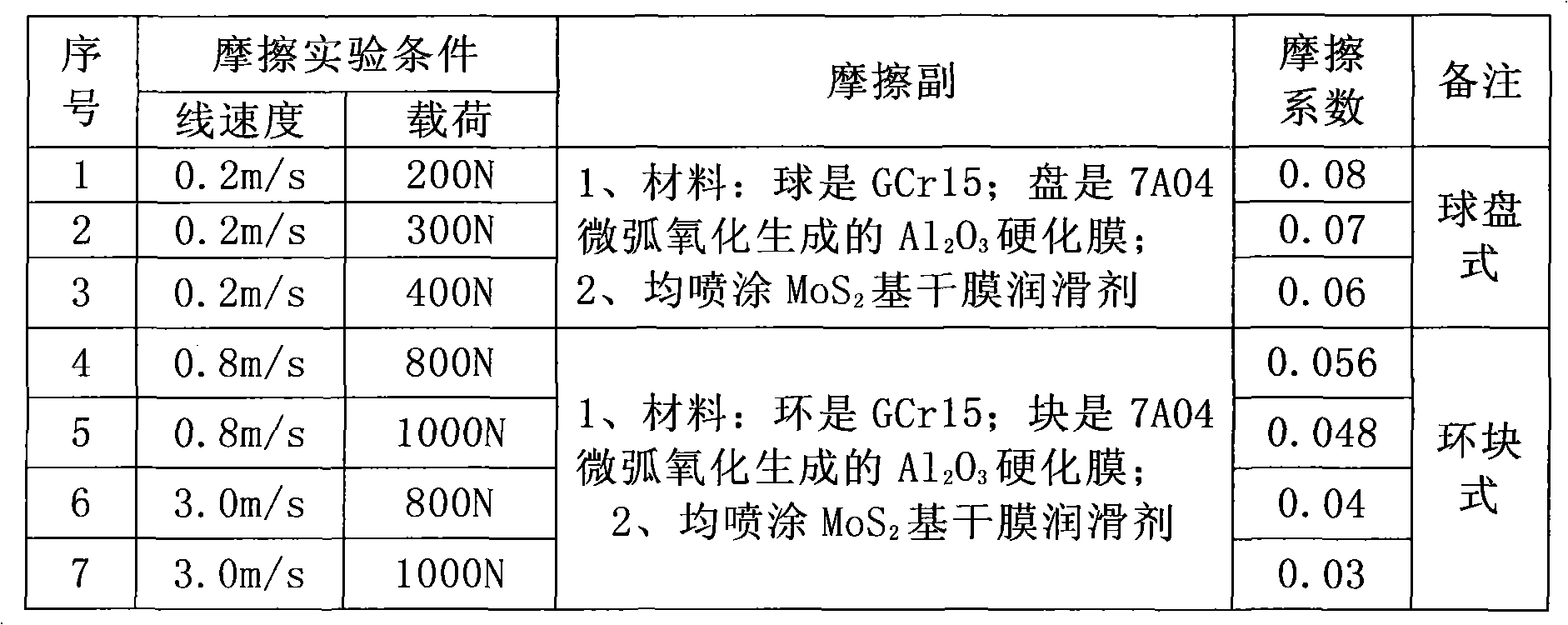

Embodiment 1

[0034] 1.1 Microarc Oxidation to Al 2 O 3 hardened film

[0035] Sample material: superhard aluminum alloy 7A04 (original brand LC4);

[0036] Micro-arc oxidation conditions:

[0037] Working temperature from room temperature to 35°C

[0038] Solution formulation Na 2 SiO 3 :H 2 O weight ratio 0.3:100

[0039] KOH:Na 2 SiO 3 Weight ratio 25:100

[0040] Voltage AC positive pulse voltage is 540V, negative pulse voltage is 150V

[0041] The current density is 15~35A / dm 2

[0042] Time 2.5 hours

[0043] Implementation results:

[0044] Al 2 o 3 The total thickness of the hardened film layer is 170um

[0045] 1.2 MAO Al 2 O 3 Grinding and cleaning of the hardened film

[0046] Sample material: Al produced by micro-arc oxidation of superhard aluminum alloy 7AO4 2 o 3 hardened film

[0047] Grinding condition: use 200 # Water sanding paper, sand evenly until black Al appears 2 o 3 Ultrasonic cleaning conditions of hardened film layer: ...

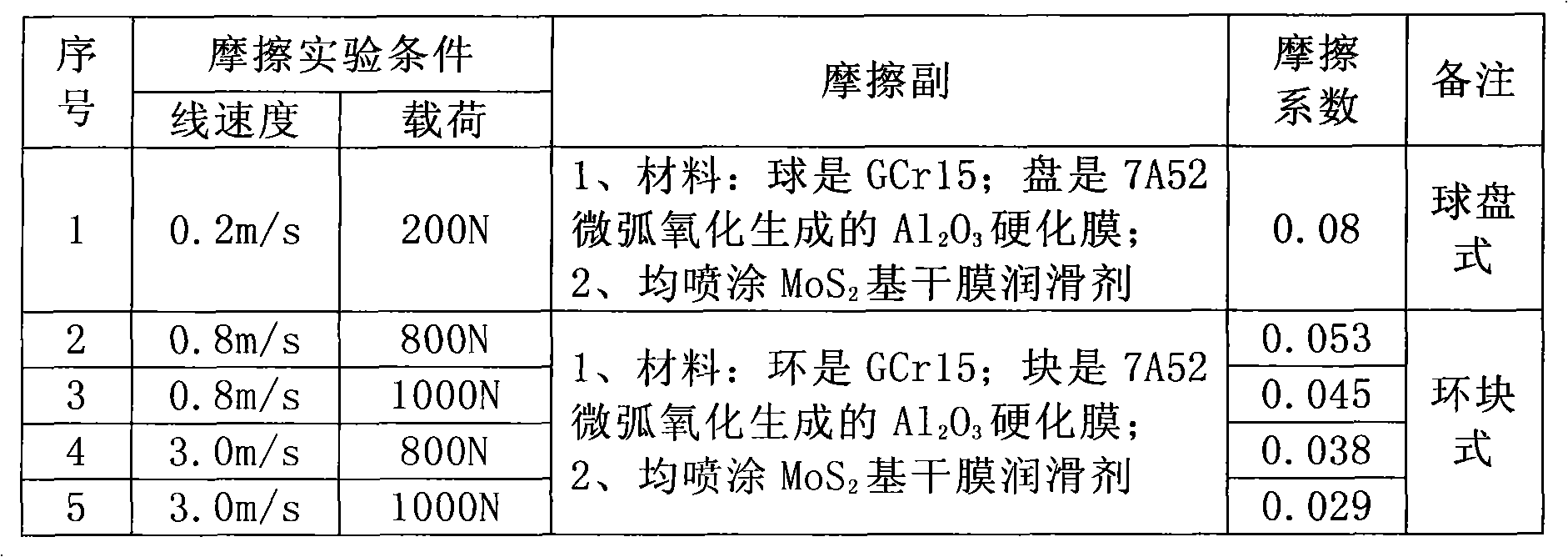

Embodiment 2

[0074] 2.1 Microarc Oxidation to Al 2 O 3 hardened film

[0075] Sample material: superhard aluminum alloy 7A52 (original brand LC52);

[0076] Micro-arc oxidation conditions:

[0077] Working temperature from room temperature to 35°C

[0078] Solution formulation Na 2 SiO 3 :H 2 O weight ratio 0.3:100

[0079] KOH:Na 2 SiO 3 Weight ratio 25:100

[0080] Voltage AC positive pulse voltage is 540V, negative pulse voltage is 130V

[0081] The current density is 15~35A / dm 2

[0082] Time 1.8 hours

[0083] Implementation results:

[0084] Al 2 o 3 The total thickness of the hardened film layer is 110um

[0085] 2.2 MAO Al 2 O 3 Grinding and cleaning of the hardened film

[0086] Sample material: Al produced by micro-arc oxidation of superhard aluminum alloy 7A52 2 o 3 hardened film

[0087] Grinding condition: use 200 # Water sanding paper, sand evenly until black Al appears 2 o 3 Ultrasonic cleaning conditions of hardened film layer: ...

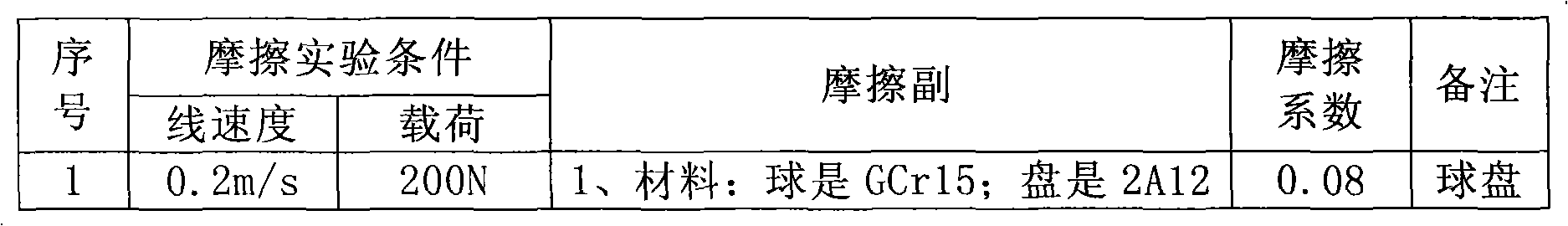

Embodiment 3

[0113] 3.1 Microarc Oxidation to Al 2 O 3 hardened film

[0114] Sample material: hard aluminum alloy 2A12 (original grade LY12);

[0115] Micro-arc oxidation conditions:

[0116] Working temperature from room temperature to 35°C

[0117] Solution formulation Na 2 SiO 3 :H 2 O weight ratio 0.5:100

[0118] KOH:Na 2 SiO 3 Weight ratio 25:100

[0119] Voltage AC positive pulse voltage is 640V, negative pulse voltage is 140V

[0120] The current density is 15~35A / dm 2

[0121] time 6 hours

[0122] Implementation results:

[0123] al 2 o 3 The total thickness of the hardened film layer is 250um

[0124] 3.2 MAO Al 2 O 3 Grinding and cleaning of the hardened film

[0125] Sample material: Al produced by micro-arc oxidation of hard aluminum alloy 2A12 2 o 3 hardened film

[0126] Grinding condition: use 100 # and 500 # Water sanding paper, sand evenly until black Al appears 2 o 3 Ultrasonic cleaning conditions of hardened film layer: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com