Electrochemical method for preparing chitosan tetracycline coating on surface of metallic implant

An implant, tetracycline technology, applied in the direction of coating, prosthesis, medical science, etc., to avoid toxic side effects, wide range of indications, mild preparation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

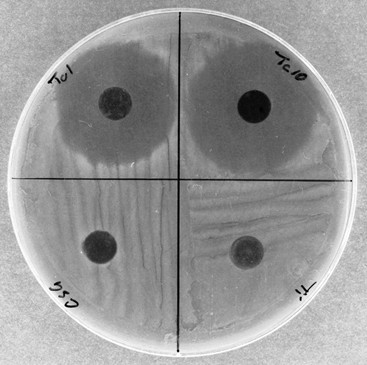

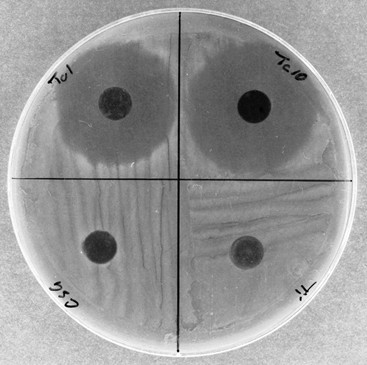

Image

Examples

Embodiment 1

[0033] 1. Prepare chitosan tetracycline mixed solution containing 0.1g / L tetracycline:

[0034] 1) Weigh 1 g of chitosan, dissolve in 100 mL of acetic acid solution, and magnetically stir until completely dissolved;

[0035] 2) Add 0.01g tetracycline under the condition of avoiding light, and magnetically stir until completely dissolved;

[0036] 3) The pH value of the above mixed solution is 3.3.

[0037] 2. Electrodeposition reaction:

[0038] 1) The platinum sheet is used as the anode, the titanium implant is used as the cathode, and the chitosan tetracycline mixed solution is used as the electrodeposition solution;

[0039] 2) The anode and cathode are immersed in the electrodeposition solution, and the distance between the two electrodes is 5cm;

[0040] 3) Control the energized direct current between the two electrodes to 1A / cm 2

[0041] 4) After 2 minutes of deposition, a layer of chitosan tetracycline coating with excellent combination with it was formed on the...

Embodiment 2

[0046] 1. Prepare chitosan tetracycline mixed solution containing 1g / L tetracycline:

[0047] 1) Weigh 1 g of chitosan, dissolve it in 100 mL of acetic acid solution, and stir until completely dissolved.

[0048] 2) Add 0.1g of tetracycline under the condition of avoiding light, and magnetically stir until completely dissolved.

[0049] 3) The pH value of the above mixed solution is 3.2.

[0050] 2. Electrodeposition reaction:

[0051] 1) The platinum sheet is used as the anode, the titanium alloy (TiAlV) implant is used as the cathode, and the chitosan tetracycline mixed solution is used as the electrodeposition solution;

[0052] 2) The anode and cathode are immersed in the electrodeposition solution, and the distance between the two electrodes is 5cm;

[0053] 3) Control the energized direct current between the two electrodes to be 4A / cm 2 ;

[0054] 4) After 2 minutes of deposition, a layer of chitosan tetracycline coating with excellent combination with it is forme...

Embodiment 3

[0059] 1. Prepare chitosan tetracycline mixed solution containing 10g / L tetracycline:

[0060] 1) Weigh 1 g of chitosan, dissolve it in 100 mL of hydrochloric acid solution, and stir until completely dissolved.

[0061] 2) Add 1g of tetracycline under the condition of avoiding light, and magnetically stir until completely dissolved.

[0062] 3) The pH value of the above mixed solution is 2.7.

[0063] 2. Electrodeposition reaction:

[0064] 1) The platinum sheet is used as the anode, the stainless steel implant is used as the cathode, and the chitosan tetracycline mixed solution is used as the electrodeposition solution;

[0065] 2) The anode and cathode are immersed in the electrodeposition solution, and the distance between the two electrodes is 5cm;

[0066] 3) Control the energized DC voltage between the two electrodes to 1V / cm 2 ;

[0067] 4) After 2 minutes of deposition, a layer of chitosan tetracycline coating with excellent combination with it is formed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com