Circulating pickling device for pipeline

A technology for circulating pickling and pipelines, applied in the field of pipeline pickling, can solve problems such as affecting cleaning, secondary pollution, and stimulating the respiratory tract of operators, and achieve the effects of reducing acid loss, low use cost, and avoiding impact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

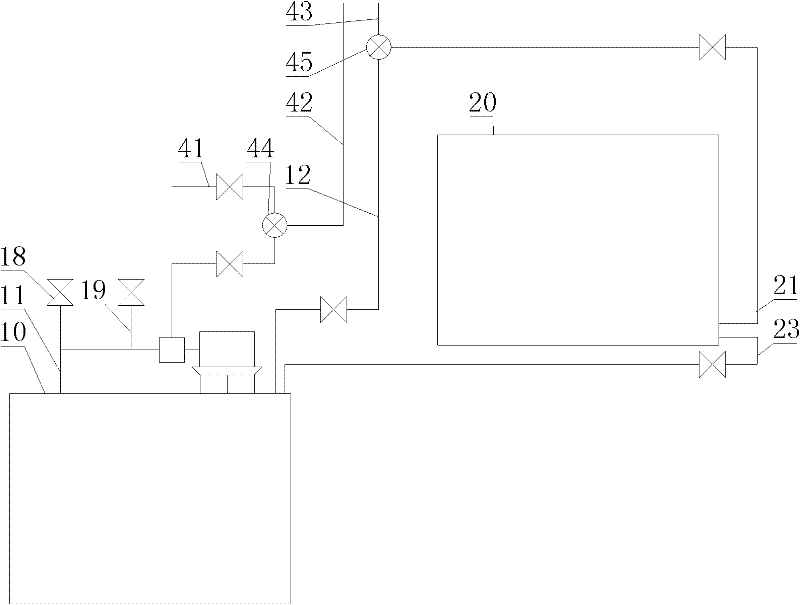

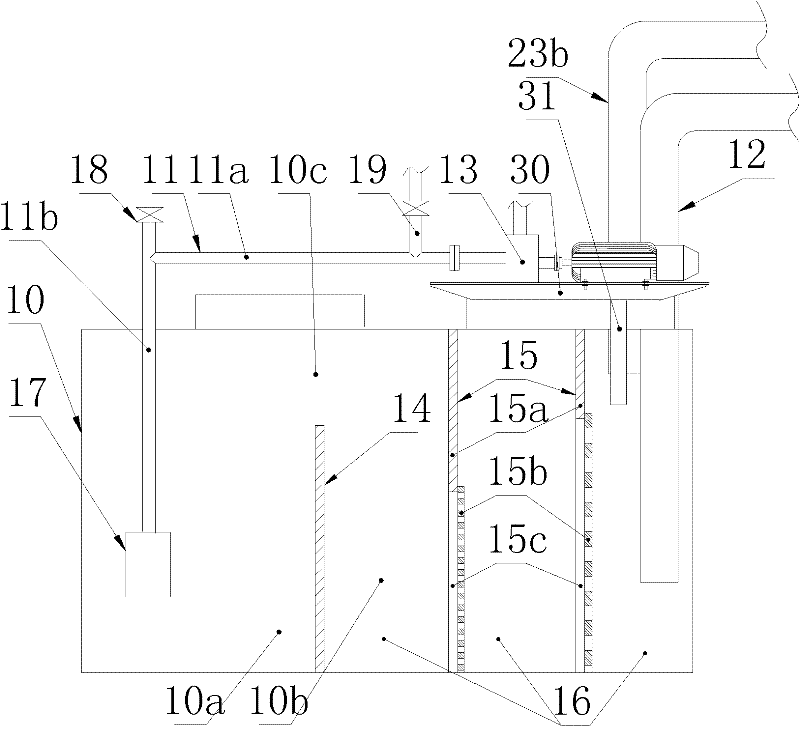

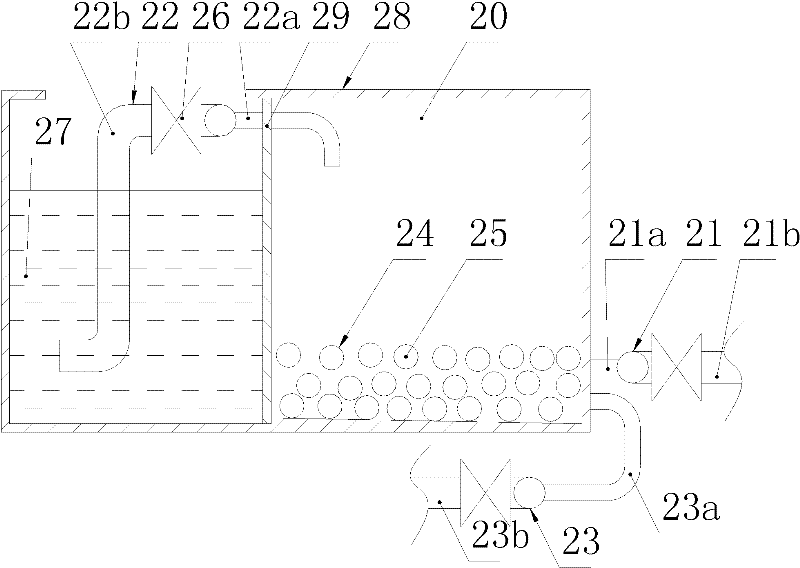

[0029] Such as figure 1 , figure 2 , image 3As shown, the pipe circulation pickling device of the present invention includes an acid tank 10, an acid delivery pipe 11 and an acid return pipe 12 respectively connected with the acid tank 10, an acid pump 13 arranged on the acid delivery pipe 11, a compressed gas source , the trachea 41 that communicates with the gas source is provided with residual acid recovery device, inlet main pipe 42, outlet main pipe 43, and described residual acid recovery device includes airtight cavity type recovery tank 20, recovery pipe 21, exhaust pipe 22, acid discharge pipe 23; the air pipe 41 and the acid delivery pipe 11 are all communicated with the inlet main pipe 42 through the inlet switching valve 44, and the acid return pipe 12 and the recovery pipe 21 are all communicated with the outlet main pipe 43 through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com