Two-component polyurethane coating used for automobile and preparation method thereof

A two-component polyurethane and coating technology, used in anti-corrosion coatings and other directions, can solve problems such as yellowing, and achieve the effects of improving gloss, improving weather resistance and stone resistance, and improving interlayer adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

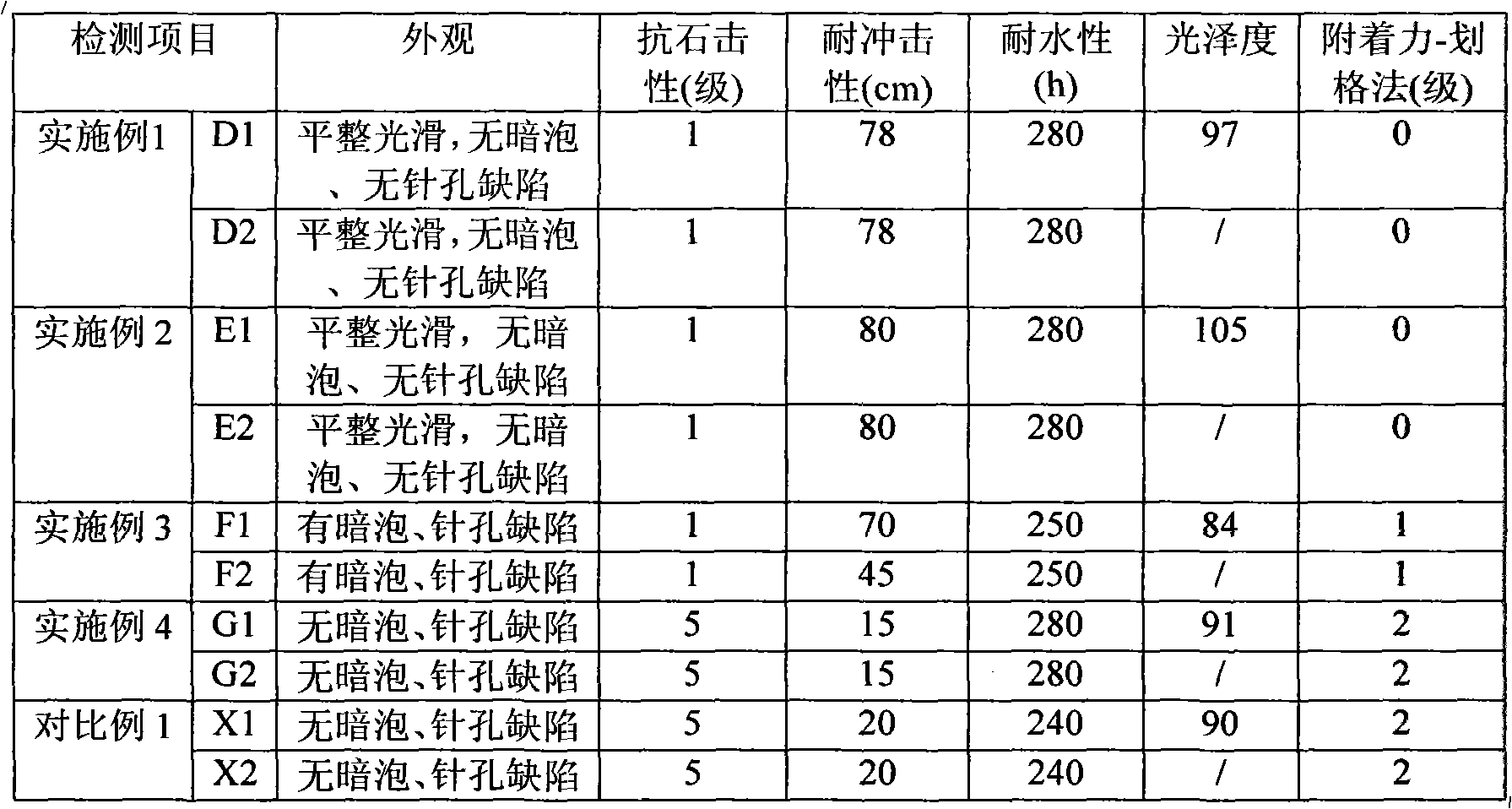

Examples

Embodiment 1

[0043] In terms of mass percentage, the content of each raw material component of a two-component polyurethane coating A component mixture for automobiles is:

[0044] RT-9020 30%

[0045] PBA2000 8%

[0047] Talc 8%

[0049] Titanium dioxide 12%

[0050] Carbon black 0.06%

[0052] Aluminum tripolyphosphate 3%

[0054] Anti-Terra-203 1.5%

[0055] BYK-310 2%

[0056] T-12 0.64%

[0057] UV1130 2%

[0058] Mixed solvent 10%

[0059] Hydroxy acrylic resin is RT-9020 produced by Jiangsu Rongtai Chemical Co., Ltd. The linear saturated polyester is PBA2000 (sold by Guangzhou Petrochemical General Factory). Fillers are barium sulfate, talc and calcium carbonate. The coloring pigments are titanium dioxide and carbon black. The anticorrosion pigments are zinc phosphate, aluminum tripolyphosphate and zinc powder. Additives include wetting and dispersing agent...

Embodiment 2

[0065] In terms of mass percentage, the content of each raw material component of a two-component polyurethane coating component A mixture is:

[0066] RT-9020 33%

[0067] PBA2000 9%

[0069] Talc 7%

[0071] Titanium dioxide 10%

[0072] Carbon black 0.1%

[0074] Aluminum tripolyphosphate 3%

[0075] Zinc powder 3%

[0076] Anti-Terra-203 1.3%

[0077] BYK-310 1.8%

[0078] T-12 0.8%

[0079] UV1130 3%

[0080] Mixed solvent 10%

[0081] Prepare the component A mixture according to the method and steps described in Example 1.

[0082] The B component mixture was prepared according to the recipe described in Example 1.

[0083] The diluent is ethylene glycol ethyl ether acetate:toluene:propylene glycol butyl ether=1:2:2.

[0084] According to the weight ratio A / B / thinner = 5 / 1 / 1, spray on the iron plate with anti-rust primer produced by DuPont, dry it for 5 minutes, and bake it a...

Embodiment 3

[0086] In terms of mass percentage, the content of each raw material component of a two-component polyurethane coating component A mixture is:

[0087] RT-9020 33%

[0088] PBA2000 8%

[0090] Talc 8%

[0092] Titanium dioxide 11.9%

[0093] Carbon black 0.1%

[0094] Zinc Phosphate 9%

[0095] Aluminum tripolyphosphate 4%

[0096] Zinc powder 3%

[0097] Anti-Terra-203 1%

[0098] T-12 0.5%

[0099] UV1130 3%

[0100] Mixed solvent 4.5%

[0101] Prepare the component A mixture according to the method and steps described in Example 1.

[0102] The B component mixture was prepared according to the recipe described in Example 1.

[0103] The diluent is ethylene glycol ethyl ether acetate:toluene:propylene glycol butyl ether=1:2:2.

[0104] According to the weight ratio A / B / thinner = 5 / 1 / 1, spray on the iron plate with anti-rust primer produced by DuPont, dry it for 5 minutes, and bake it at 60°C for 30 minut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com