Chemical plating Ni-P alloy technology of glass micro beads

A glass microbead and alloy process technology, applied in the field of glass microbead electroless plating Ni-P alloy process, can solve problems such as poor uniformity of Ni-P deposition layer, and achieve good anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] A kind of glass microbead chemical plating Ni-P alloy process, comprises the steps:

[0065] (1) Ultrasonic degreasing of glass beads, the composition and content of the ultrasonic degreasing liquid are as follows:

[0066] Sodium hydroxide 10 g / L

[0067] Sodium carbonate 15g / L

[0068] Sodium Phosphate 35 g / L

[0069] OP-10 emulsifier 10 mL / L

[0070] The ultrasonic process controls the temperature at 25°C for 3 minutes, then pours out the electrolyte, and washes the glass beads with distilled water for 4 times until no degreasing electrolyte remains on the surface of the beads;

[0071] (2) For glass beads sensitization, the composition and content of the sensitization solution are as follows:

[0072] Stannous chloride 15 g / L

[0073] Hydrochloric acid (content 37%) 100 mL / L

[0074] During the sensitization process, the temperature is controlled at 25°C and the sensitization time is 2 minutes, then the electrolyte is poured out, and the glass beads are washed...

Embodiment 2

[0088] A kind of glass microbead chemical plating Ni-P alloy process, comprises the steps:

[0089] (1), with embodiment 1;

[0090] (2), with embodiment 1;

[0091] (3), with embodiment 1;

[0092] (4) During the electroless Ni-P plating process, the temperature is controlled at 60° C., and other conditions are the same as those in Example 1.

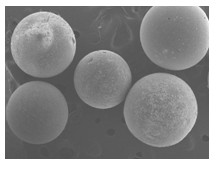

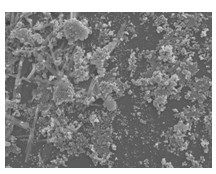

[0093] When the glass beads are put into the plating solution and stirred intermittently for electroless plating, since the reaction speed of the electroless plating is moderate at this temperature, a uniform, continuous and bright Ni-P alloy deposition layer can be formed on the surface of all the beads, and the plating There are no free metal particles in the liquid and between the beads, Figure 2a and Figure 2b is the SEM morphology of microbeads and coatings on the surface of microbeads when the temperature of the plating solution is 60°C and the plating time is 30 minutes. Figure 2a and Figure 2b It is concluded that aft...

Embodiment 3

[0096] A kind of glass microbead chemical plating Ni-P alloy process, comprises the steps:

[0097] (1) Ultrasonic degreasing of glass beads, the composition and content of the ultrasonic degreasing liquid are as follows:

[0098] Sodium hydroxide 5 g / L

[0099] Sodium carbonate 10g / L

[0100] Sodium Phosphate 30 g / L

[0101] OP-10 emulsifier 5 mL / L

[0102] The ultrasonic process controls the temperature at 25°C for 3 minutes, then pours out the electrolyte, and washes the glass beads with distilled water for 4 times until no degreasing electrolyte remains on the surface of the beads;

[0103] (2) For glass beads sensitization, the composition and content of the sensitization solution are as follows:

[0104] Stannous chloride 10 g / L

[0105] Hydrochloric acid (content 37%) 50 mL / L

[0106] During the sensitization process, the temperature is controlled at 25°C and the sensitization time is 2 minutes, then the electrolyte is poured out, and the glass beads are washed wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com