MCM-22 zeolite molecular sieve containing rare earth heteroatoms in skeleton and preparation method thereof

A technology of MCM-22 and zeolite molecular sieve, applied in the direction of crystalline aluminosilicate zeolite, etc., to achieve the effect of reducing production difficulty, good repeatability and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

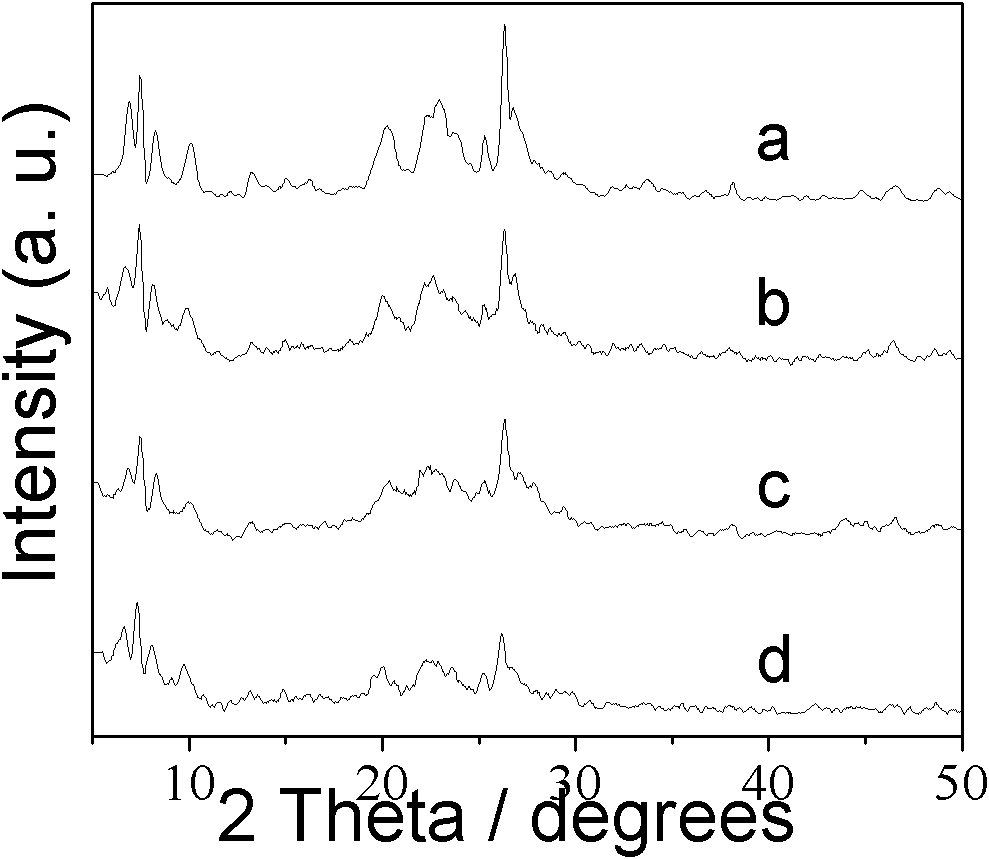

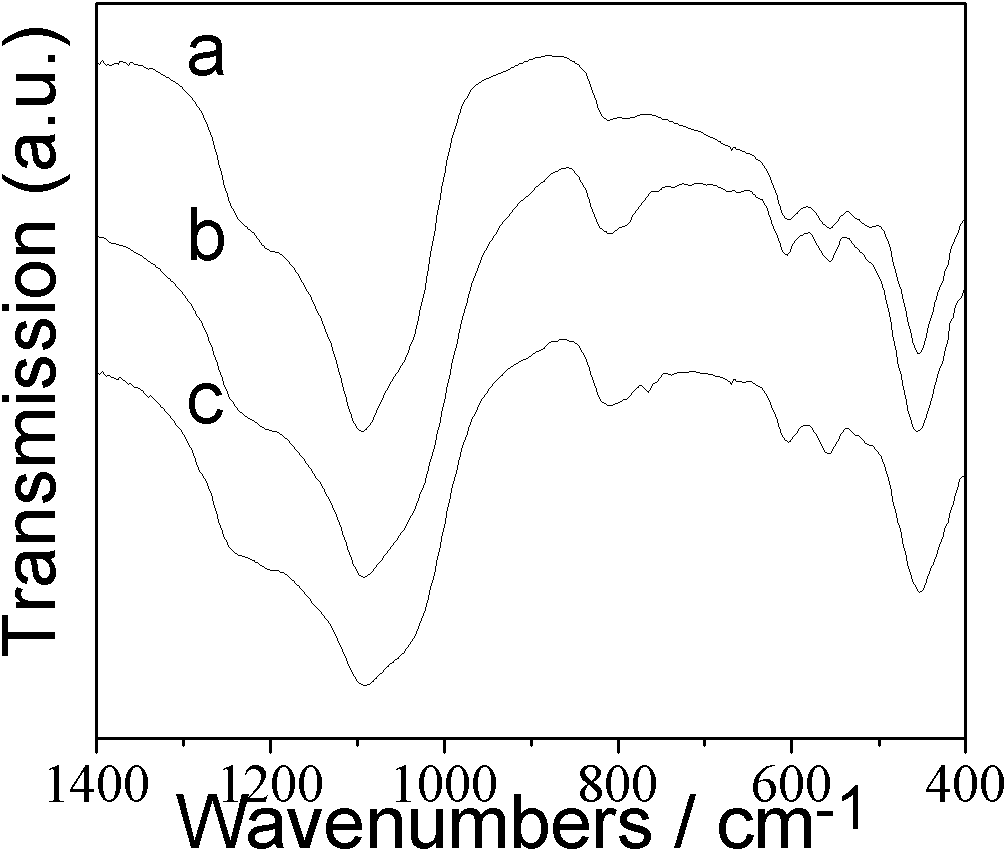

[0031] Take 11.31g of ethyl orthosilicate and 0.231g of lanthanum nitrate, add 10.25ml of 0.3M hydrochloric acid aqueous solution to them, adjust the hydrolysis pH of the solution to 2.0, stir and hydrolyze at 90℃ for 2 hours, then add 3.44ml of hexamethylene Imine, make A solution; Dissolve 0.315g sodium hydroxide and 0.415g sodium aluminate in 8.4ml deionized water to make B solution, slowly add solution B dropwise to solution A, stir well, make The molar ratio of the total composition of the mixture is SiO 2 :0.125Na 2 O: 0.033Al 2 O 3 : 0.01RE: 0.6HMI: 20H 2 O, packaged in a high-pressure hydrothermal reactor, crystallized at 158°C for 10 days, washed the resulting product to neutrality, centrifuged, dried, and roasted. The product was characterized by X-ray diffraction and infrared spectroscopy, and the product was finally obtained. It is a lanthanum-doped MCM-22 zeolite molecular sieve. See its X-ray diffraction spectrum (XRD) figure 1 a, see infrared spectrum (IR) figur...

Embodiment 2

[0033] According to the operating steps and operating conditions of Example 1, the difference is that the rare earth compound is cerium nitrate. The X-ray diffraction and infrared spectroscopy characterization results of the product prove that the final product is a cerium-doped MCM-22 zeolite molecular sieve. See its X-ray diffraction spectrum (XRD) figure 1 b, see infrared spectrum (IR) figure 2 b. The Ce / Si (molar ratio) in the molecular sieve was measured by inductively coupled plasma spectroscopy (ICP) = 0.0083.

Embodiment 3

[0035] According to the operating steps and operating conditions of Example 1, the difference is that the rare earth compound is samarium nitrate, and the product is proved by XRD diffraction: the final product is a samarium-doped MCM-22 zeolite molecular sieve. Its X-ray diffraction spectrum (XRD) see figure 1 c. The Sm / Si (molar ratio) in the molecular sieve was measured by inductively coupled plasma spectroscopy (ICP) = 0.0060.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com