Resistance switch material in Ag/Ag2S core/shell nanometer structure and preparation method thereof

A resistance switch and nanostructure technology, applied in the coating and other directions, can solve the problems of weak electronic signal of resistance switch, difficult to achieve industrial amplification, difficult application, etc., to achieve the effect of easy mass production, convenient industrial amplification, and enhanced current signal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

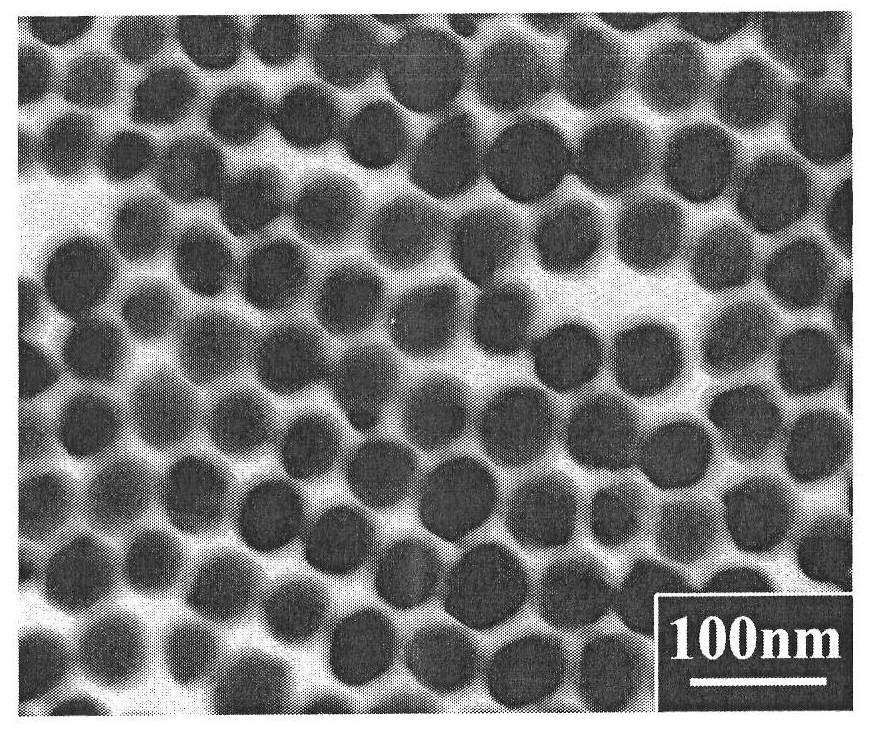

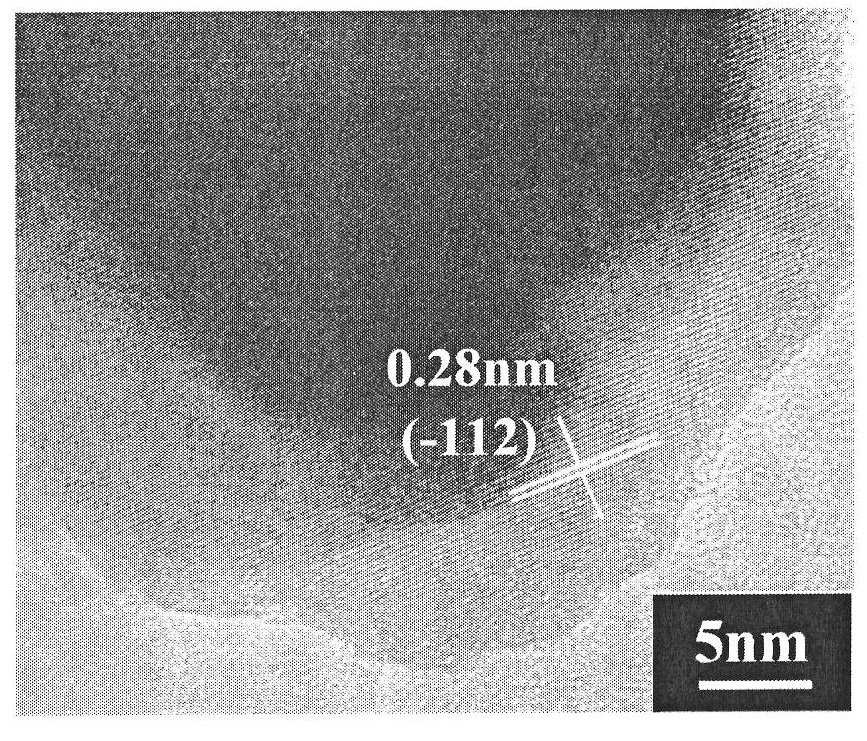

[0037]Add 10 grams of PVP (K30) to 50 ml of ethylene glycol, stir it electromagnetically, heat it to 190°C, then add 0.1 g of silver nitrate, and keep it at 190°C for 5 minutes; then, add 5 mg of sulfur powder and react at 190°C After 10 minutes, wash the precipitate obtained from the reaction with ethanol, and dry it at 40-80°C to obtain Ag / Ag with a particle size of 10-15 nanometers. 2 S core / shell nanocrystals.

Embodiment 2

[0039] In 50ml of ethylene glycol, add 10g of PVP (K30), electromagnetically stir, heat to 180°C, then add 0.5g of silver nitrate, keep at 180°C for 10 minutes; then, add 20mg of sulfur powder, at 180°C React for 10 minutes, wash the precipitate obtained by the reaction with ethanol, and disperse it in 5 ml of ethanol to obtain Ag / Ag with a particle size of 50-60 nm and a shell thickness of 5-10 nm. 2 S core / shell nanocrystalline dispersoid;

[0040] Take 50 microliters of colloid in an area of about 0.5 x 0.5 cm 2 Spin-coat the aluminum sheet to form a film, and then assemble a resistive switch with two films, measure the I-V curve, see Image 6 .

Embodiment 3

[0042] In 50ml of ethylene glycol, add 10g of PVP (K30), electromagnetically stir, heat to 160°C, then add 0.5g of silver nitrate, keep at 160°C for 10 minutes; then add 10mg of sulfur powder and react at 160°C After 10 minutes, wash the precipitate obtained by the reaction with ethanol, and dry it at 40-80°C to obtain Ag / Ag with a particle size of 60-80 nanometers and a shell thickness of 2-5 nanometers. 2 S core / shell nanocrystals.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| Shell thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com