Inverter type scroll compressor

A scroll compressor, variable frequency technology, applied in the direction of rotary piston machinery, mechanical equipment, machine/engine, etc., can solve the problems of temperature increase, compressor efficiency reduction, energy consumption increase, etc., to reduce the degree of overheating, improve Heat exchange efficiency and energy consumption reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

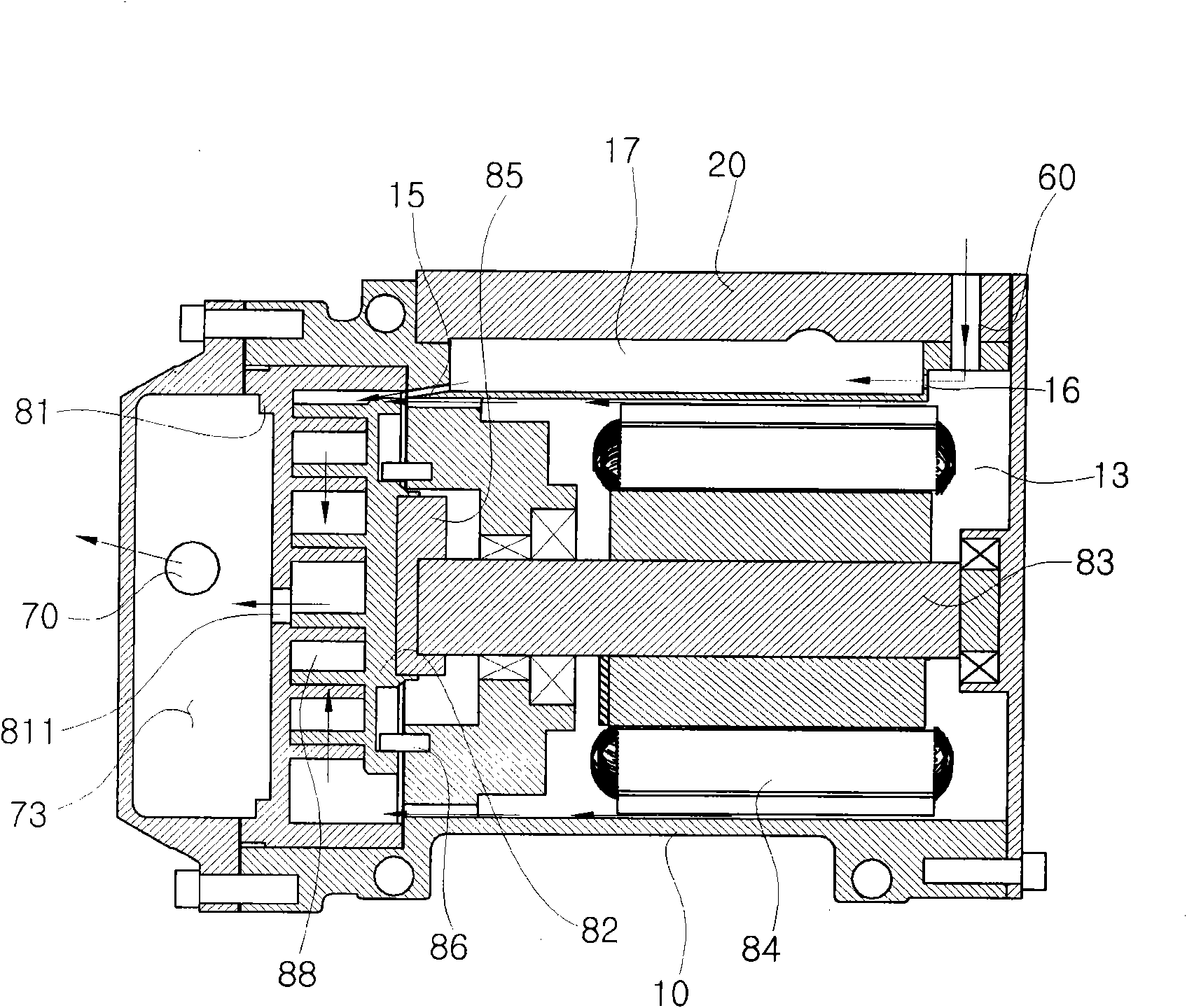

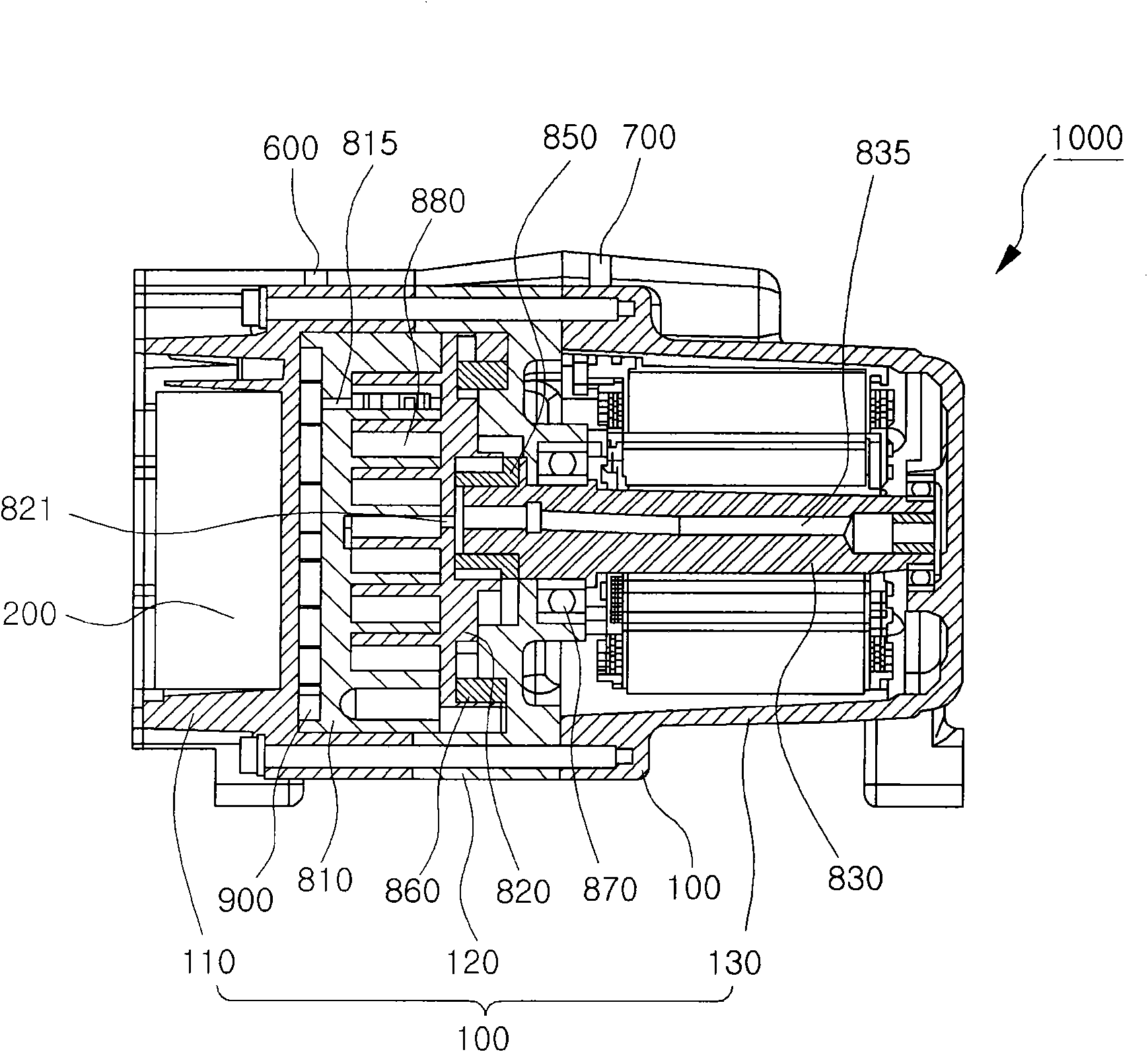

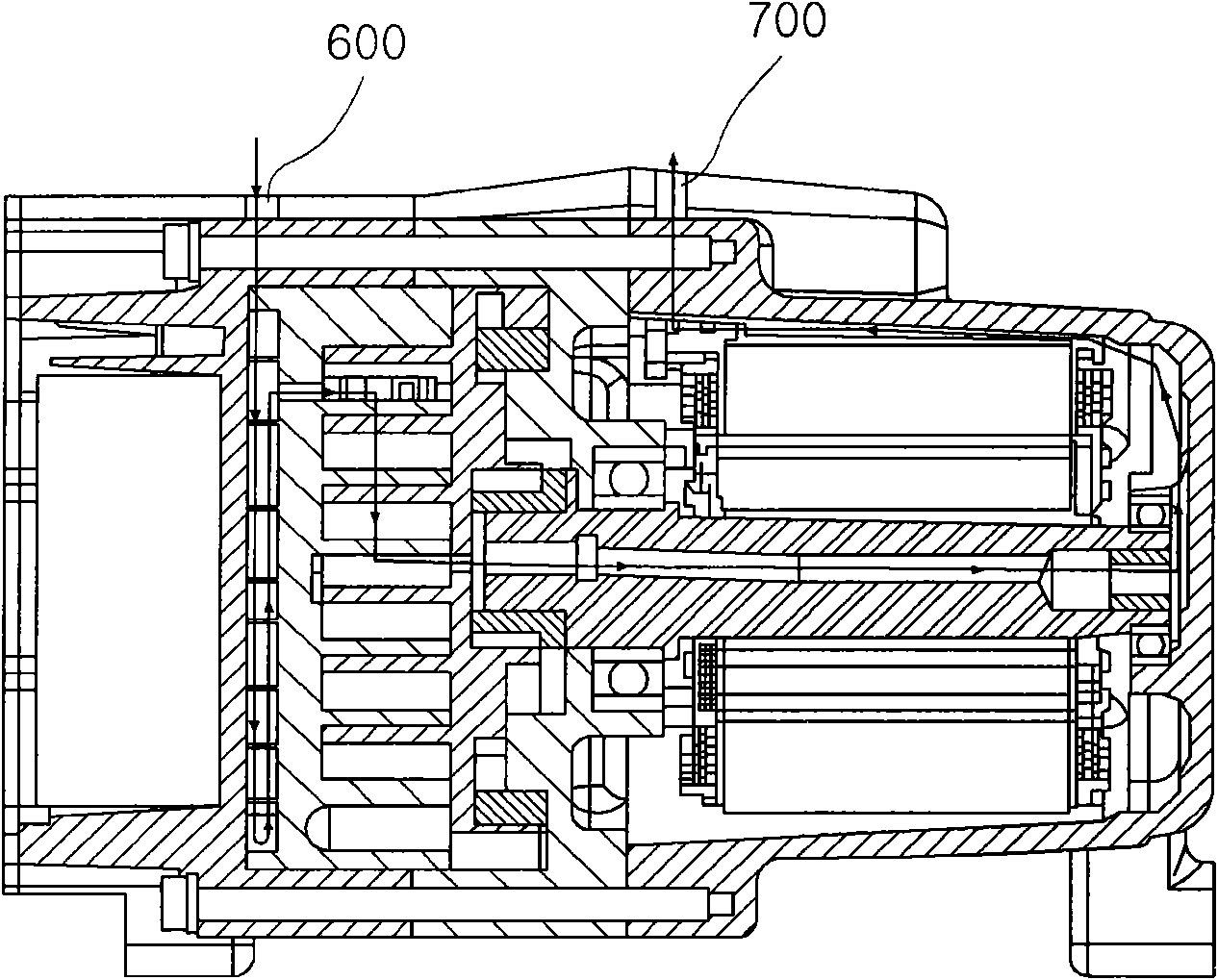

[0037] Refer below Figure 2 to Figure 5 A preferred embodiment of the present invention will be described in more detail.

[0038] As shown in the figure, the variable frequency scroll compressor 1000 of the present invention includes a casing 100, a suction port 600 and a discharge port 700 arranged in the casing 100, a pair of two meshes that are accommodated in the casing 100 and engaged with each other. Fixed scroll 810 and an orbiting scroll 820; a drive shaft 830; a motor 840; a motor 840 installed between the end of the drive shaft 830 and the orbiting scroll 820 to drive the orbiting scroll 820 to orbit ( and an anti-rotation mechanism 860 for preventing the orbiting scroll 820 from rotating, such as an Oldham ring. The driving shaft 830 , the motor 840 , the sliding sleeve 850 and the anti-rotation mechanism 860 constitute the orbiting motion driving part of the orbiting scroll 820 .

[0039] Such as figure 2 and Figure 4 As shown, the housing 100 includes a fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com