Method for setting in-furnace tension of continuous annealing unit on line

A technology of tension setting and setting method, which is applied in the direction of furnace, furnace type, heat treatment furnace, etc., can solve the problems of no consideration of influence, difference, and large difference, so as to improve stability, maximize economic benefits, and reduce running Partial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

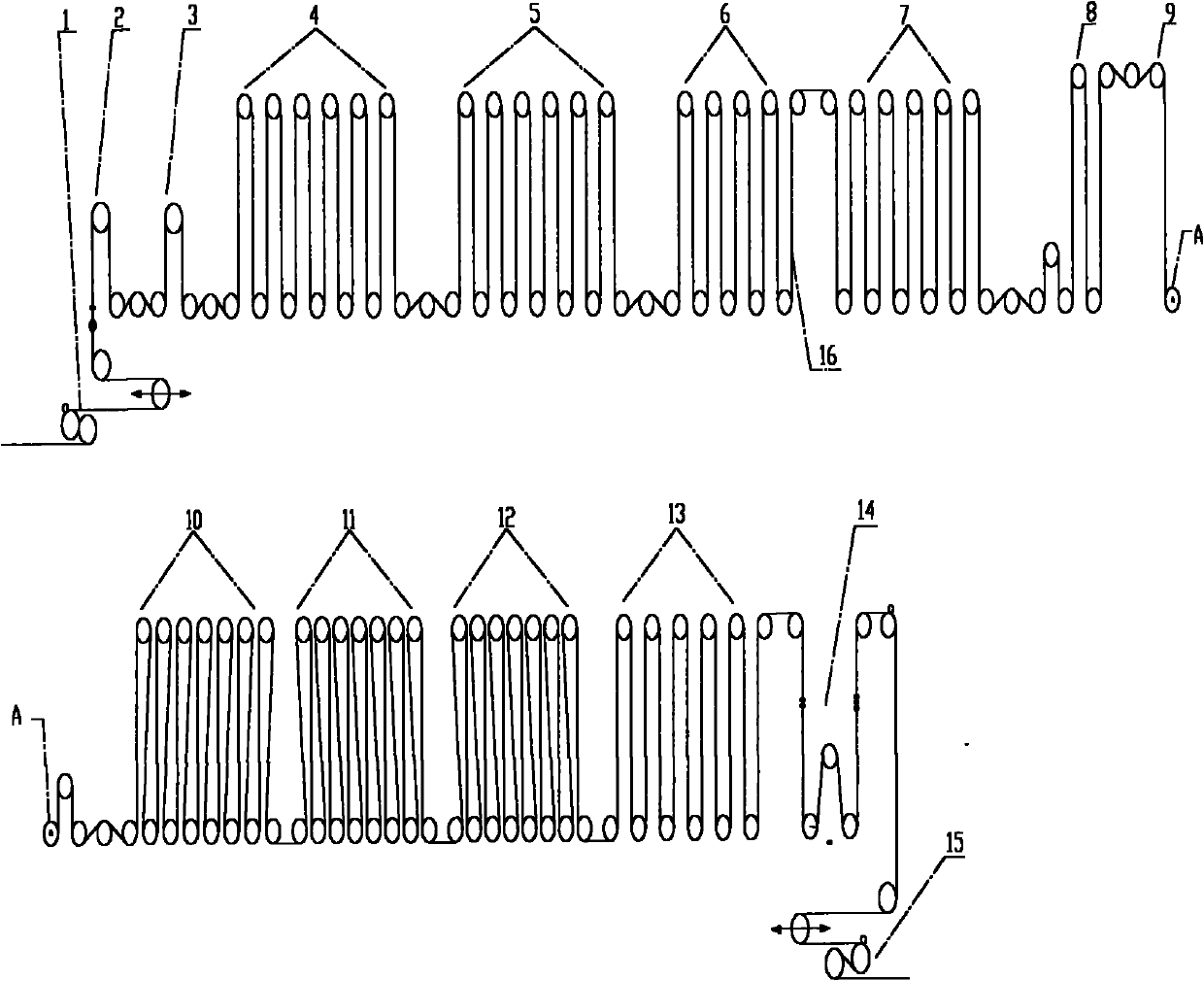

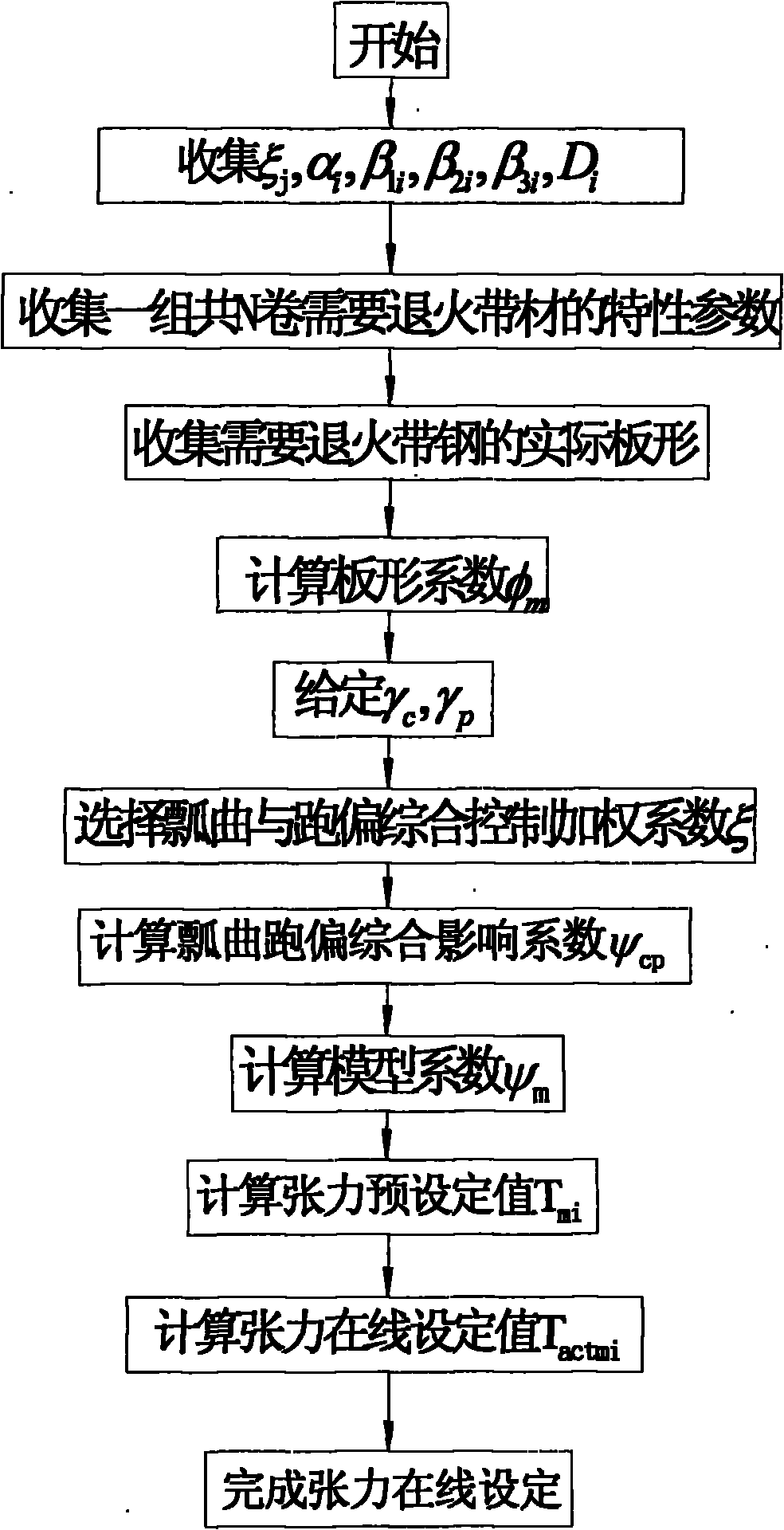

[0040] In order to illustrate the basic idea of the present invention, now take a certain 1850 continuous annealing unit as an example, with the help of figure 2 To describe the online tension setting process of mild steel on a specific continuous annealing unit.

[0041] First, in step 1, the influence coefficient ξ of the equipment structure characteristics of the continuous annealing furnace is collected j (j=1, 2, L, 7), continuous annealing furnace segmental influence coefficient α i , β 1i , β 2i , β 3i (i=1, 2, L, 11), the furnace roller diameter D of each section of the continuous annealing furnace i (i=1, 2, L, 11), as shown in Table 1 and Table 2:

[0042] Table 1 Influence coefficient of furnace structure characteristics of 1850 continuous annealing unit

[0043] project

ξ 1

ξ 2

ξ 3

ξ 4

ξ 5

ξ 6

ξ 7

value

0.6082

-4.4339

12.44

-16.792

2.0589

-8.353...

Embodiment 2

[0074] In order to further illustrate the basic idea of the present invention, a certain 1850 continuous annealing unit is now taken as an example, with the help of figure 2 To describe the online tension setting process of hard steel on a specific continuous annealing unit.

[0075] First, in step 1, the influence coefficient ξ of the equipment structure characteristics of the continuous annealing furnace is collected j (j=1, 2, L, 7), continuous annealing furnace segmental influence coefficient α i , β 1i , β 2i , β 3i (i=1, 2, L, 11), the furnace roller diameter D of each section of the continuous annealing furnace i (i=1, 2, L, 11), as shown in Table 1 and Table 2:

[0076] Table 1 Influence coefficient of furnace structure characteristics of 1850 continuous annealing unit

[0077] project

ξ 1

ξ 2

ξ 3

ξ 4

ξ 5

ξ 6

ξ 7

value

0.6082

-4.4339

12.44

-16.792

2.0589

-8.3535

15.52...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com