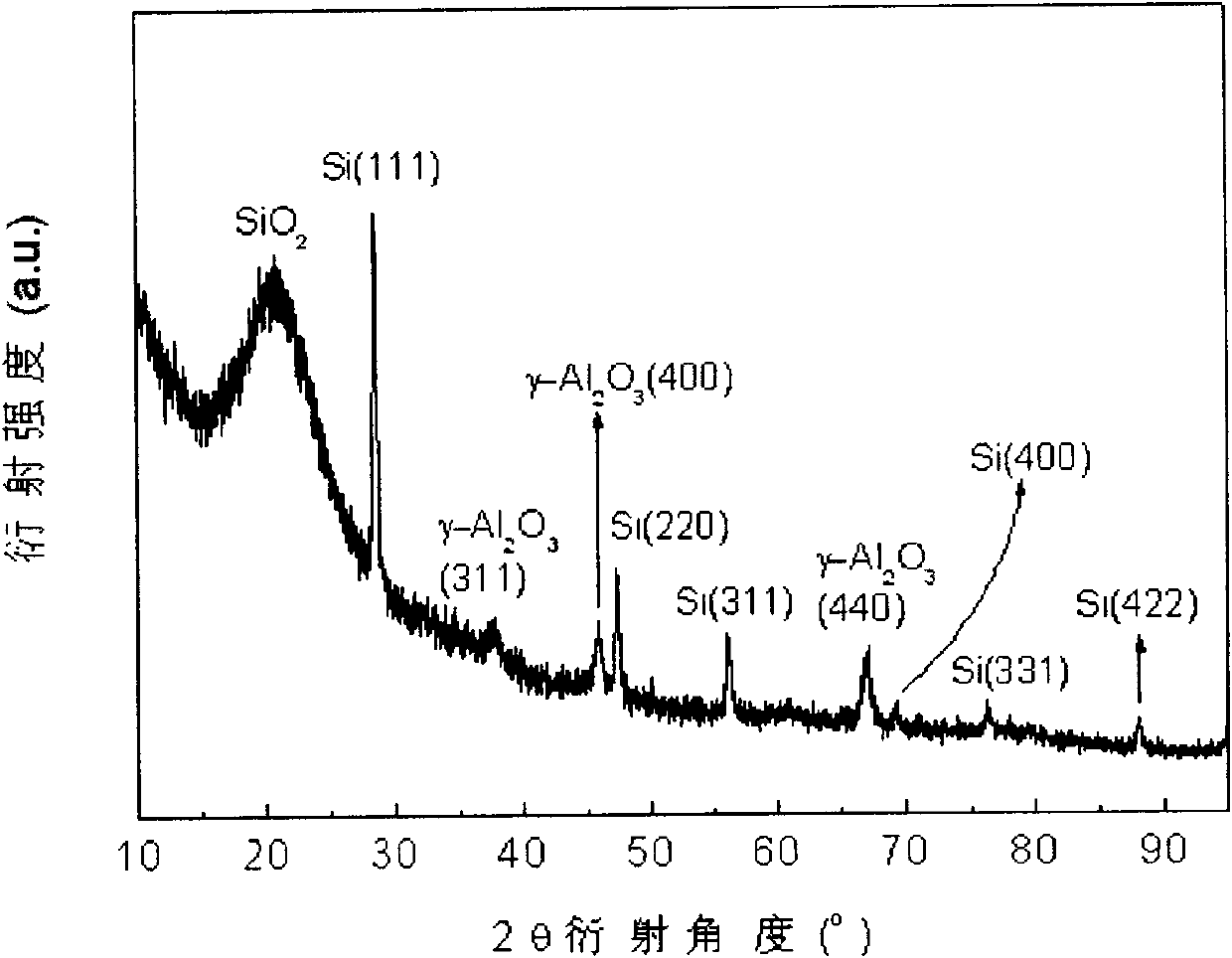

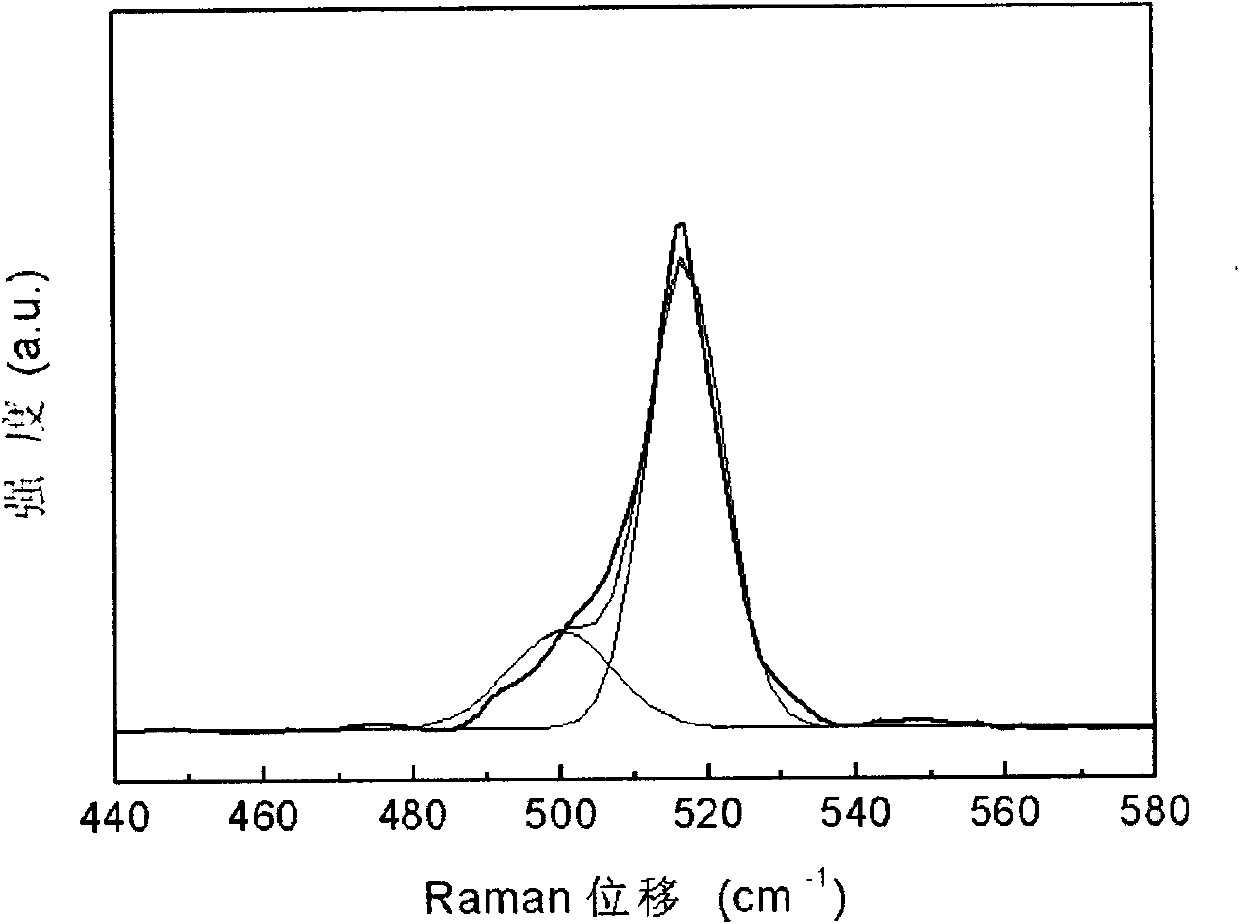

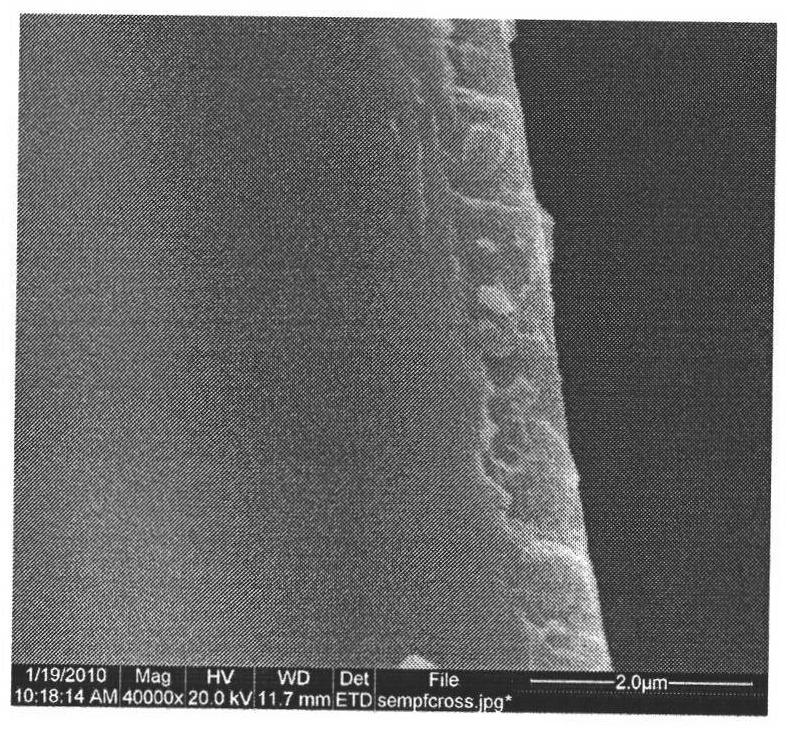

Preparation method of nanocrystalline silicon-aluminum oxide/silicon oxide thermoelectric film material

A technology of thermoelectric thin film and nanocrystalline silicon, which is applied in the field of materials, can solve the problems of complex preparation process, small thermoelectric figure of merit of materials, and hinder development, and achieve the effect of simple preparation method, rich content and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Place a 1mm thick quartz glass substrate in 400mL of cleaning solution A mixed with hydrogen peroxide, 30% by mass percent ammonia, and deionized water at a volume ratio of 1:1:5. Use an ultrasonic generator with a power of 30W and a frequency of Clean with 30kHz ultrasonic waves at 60°C for 10 minutes, rinse with deionized water; then place in 400mL of cleaning solution B mixed with hydrogen peroxide, 30% by mass percentage of hydrochloric acid, and deionized water at a volume ratio of 1:1:5. Use an ultrasonic generator with a power of 30W and a frequency of 30kHz to clean at 60°C for 10 minutes, rinse with deionized water, and dry the cleaned quartz glass substrate with nitrogen.

[0024] 2. Vacuum evaporation aluminum film

[0025] Put the cleaned quartz glass substrate and the tungsten boat with aluminum rods with a purity of 99.999% into the vacuum chamber of the vacuum coating machine, and evacuate until the background vacuum degree of the vacuum chamber is 2×10 ...

Embodiment 2

[0039] Example 3

Embodiment 3

[0041] Example 4

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| Seeback coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com