Method for controlling water and preventing sand by using phase permeability regulator

A technology of phase permeability and regulator, applied in chemical instruments and methods, earthwork drilling, production fluids, etc., can solve problems affecting oil well productivity, energy waste, affecting development efficiency or economic benefits, etc., to extend the stable production period, The effect of reducing production costs, improving development efficiency or economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The preparation process of the phase permeability regulator is as follows: a. Add monomeric acrylic acid, propylene, sulfonated propylene and deionized water to the reaction kettle in sequence, and stir evenly; b. Heat to 90°C constant temperature; c. Stir with nitrogen gas 30min, remove the oxygen in the solution; d, add the solid initiator of mass percentage content 0.2%-0.8%, trigger it to carry out polymerization reaction under normal pressure, react 7-9 hour, obtain the target product, its molecular weight is 7 million to Ten million. The solid initiator is sodium bisulfite and ammonium persulfate with a mass ratio of 1:1-3.

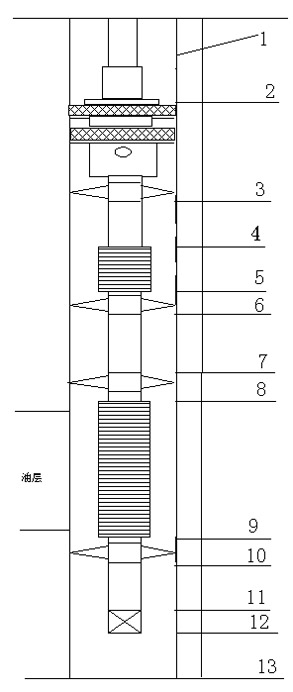

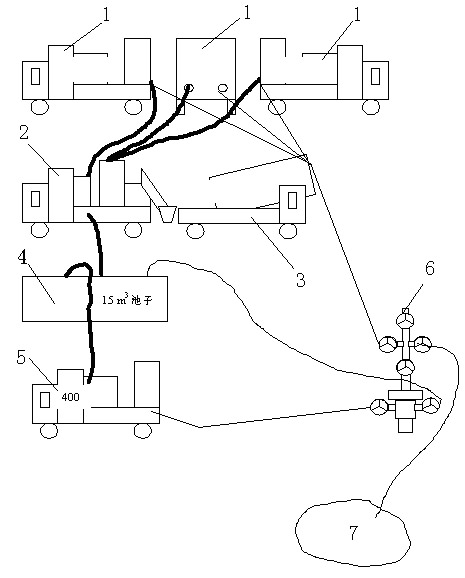

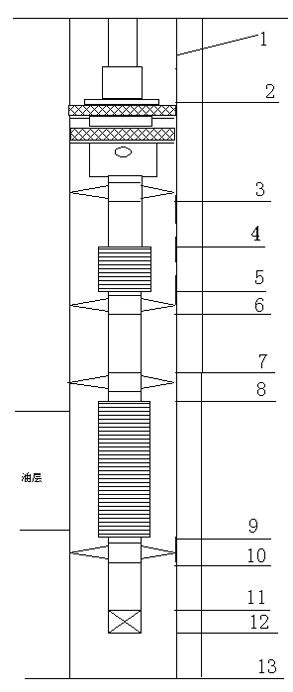

[0029] The water control and sand prevention method of the phase permeability regulator according to the present invention includes injecting the quartz sand into the target layer by carrying the sand-carrying liquid, which is characterized in that the sand-carrying liquid is compounded by the phase permeability regulator and the anti-swellin...

Embodiment 1

[0034] a. Add 5 parts of acrylic acid monomer, 2 parts of propylene monomer, 1 part of sulfonated propylene monomer, and 92 parts of deionized water into the reaction kettle in turn, and stir evenly; b. Heat to a constant temperature of 90°C; c. Stir with nitrogen for 30 minutes , remove the oxygen in the solution; d, add the solid initiator of mass percent content 0.2%, trigger it to carry out polymerization reaction under normal pressure, react 7 hours, obtain target product, its molecular weight is 7 million to 10 million. The solid initiator is sodium bisulfite and ammonium persulfate with a mass ratio of 1:1.

[0035] Add 0.2% by weight phase permeability modifier and 0.5% anti-swelling agent to ten tons of water, stir evenly under normal temperature and pressure, and make phase permeability adjustment sand-carrying liquid. Dilute the phase permeability adjustment sand-carrying liquid with water to an aqueous solution with a mass percentage of 0.5%, and the phase permeabi...

Embodiment 2

[0038] a. Add 10 parts of acrylic acid monomer, 6 parts of propylene monomer, 4 parts of sulfonated propylene monomer, and 92 parts of deionized water into the reaction kettle in turn, and stir evenly; b. Heat to a constant temperature of 90°C; c. Stir with nitrogen for 30 minutes , remove the oxygen in the solution; d, add the solid initiator of mass percentage content 0.4%, normal pressure

[0039] Initiate it to carry out polymerization reaction, react 8 hours, obtain target product, its molecular weight is 7 million to 10 million. The solid initiator is sodium bisulfite and ammonium persulfate with a mass ratio of 1:2.

[0040] Add 2.5% by weight phase permeability modifier and 1.75% anti-swelling agent to ten tons of water, and stir evenly under normal temperature and pressure to make a phase permeability adjustment sand-carrying fluid. The relative permeability adjustment sand-carrying liquid is diluted with water to an aqueous solution with a mass percentage of 1.75%, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com