Method for separating and extracting L-arginine from fermentation liquor

A technology of arginine and fermentation liquid, which is applied in the field of L-arginine extraction technology, can solve the problems of bacterial cell removal rate and low product quality, and achieve the effects of reduced extraction cost, simple and easy process, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

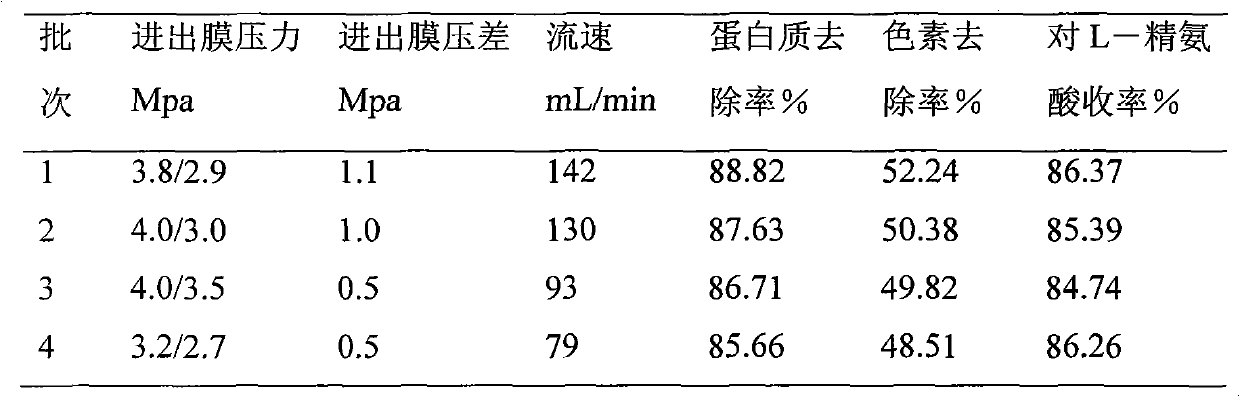

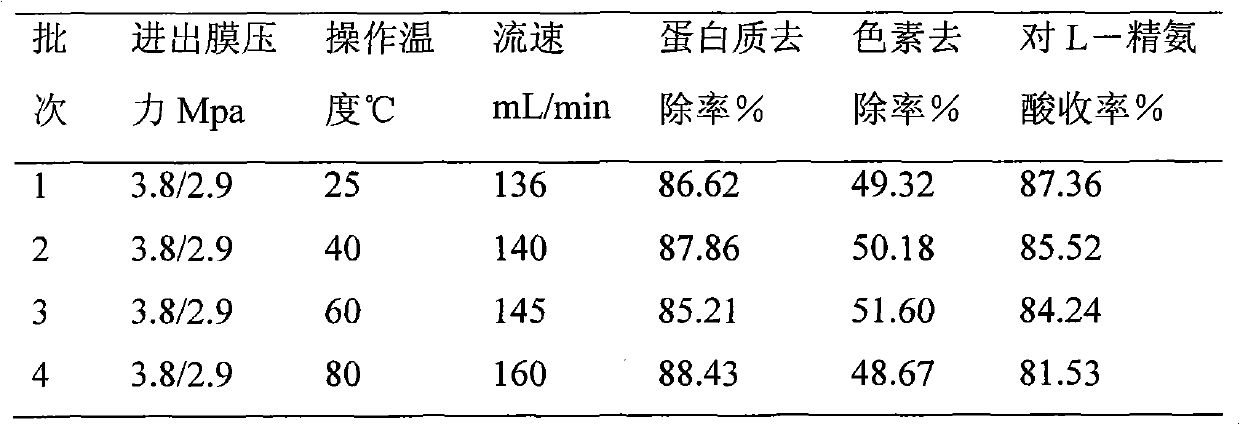

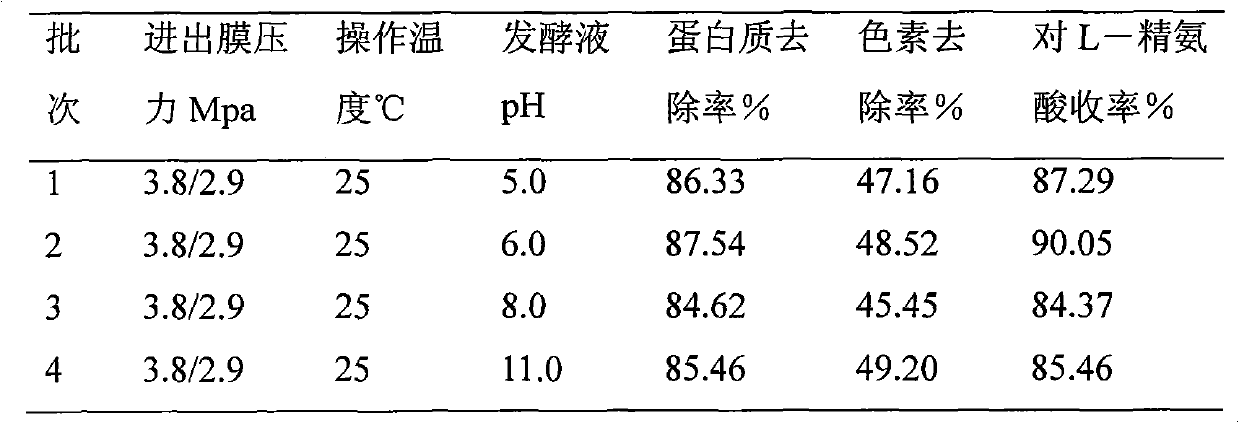

Examples

Embodiment 1

[0024] a. Take 25L of L-arginine fermentation broth and heat it at 80°C for more than 10min, adjust the pH to about 6.0, add diatomite with a volume of 0.1 to 0.5% of the fermentation broth, and then inject it into the microfiltration equipment tank. The microfiltration membrane is made of metal Membrane (the membrane system uses asymmetric porous 316L stainless steel powder as the liner to sinter TiO 2 Inert coating, pore size 50nm-100nm, molecular weight cut off 5000MW, inner diameter of membrane tube 18.3mm, outer diameter of membrane tube 21.6mm, effective filtration area 0.1m 2 Single channel, wall thickness 1.65mm, membrane tube length 80cm, maximum operating pressure 4~6Kg / cm 2 The maximum operating temperature is 200°C, the pH range is 0-14, and the system flow rate is 5-10m / s). The molecular weight cut-off of the system is 2000-50000MW. Cooling water is introduced into the condenser tube, and the temperature is controlled to 40°C. 2 , using the different retention r...

Embodiment 2

[0030] a. Take 20L of L-arginine fermentation broth and heat it at 80°C for more than 10min, adjust the pH to about 6.0, and add it to the microfiltration equipment tank. Enter the cooling water, control the temperature to 25 °C, check whether the equipment is in a normal state, start the microfiltration equipment, and adjust the pressure difference at the inlet of the membrane to 0.6kg / cm 2 , using the different retention rates of different molecular weight substances by the microfiltration membrane, so that the bacteria and impurity proteins are retained in the filter residue, and the pressure into the membrane and the pressure at the membrane outlet are 3.5kg / cm 2 and 2.5kg / cm 2 , when the pressure difference between entering and leaving the membrane is significantly reduced, an appropriate amount of deionized water is added, and after filtration, 25L of L-arginine filtrate is obtained. The protein removal rate of the filtrate is over 94%.

[0031] b. Adjust the pH of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| translucency | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

| translucency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com