Efficient environmental-friendly slow-release fertilizer and preparation method thereof

A slow-release fertilizer, an environmentally friendly technology, applied in fertilizer mixtures, fertilization devices, applications, etc., can solve the problem of weak research on key equipment and process support, less research on slow and controlled release of nutrients such as phosphorus and potassium, and it is difficult to form large-scale industrialization. and other problems, to achieve the effect of reducing agricultural non-point source pollution, simplifying fertilization operations, and obtaining easy access.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

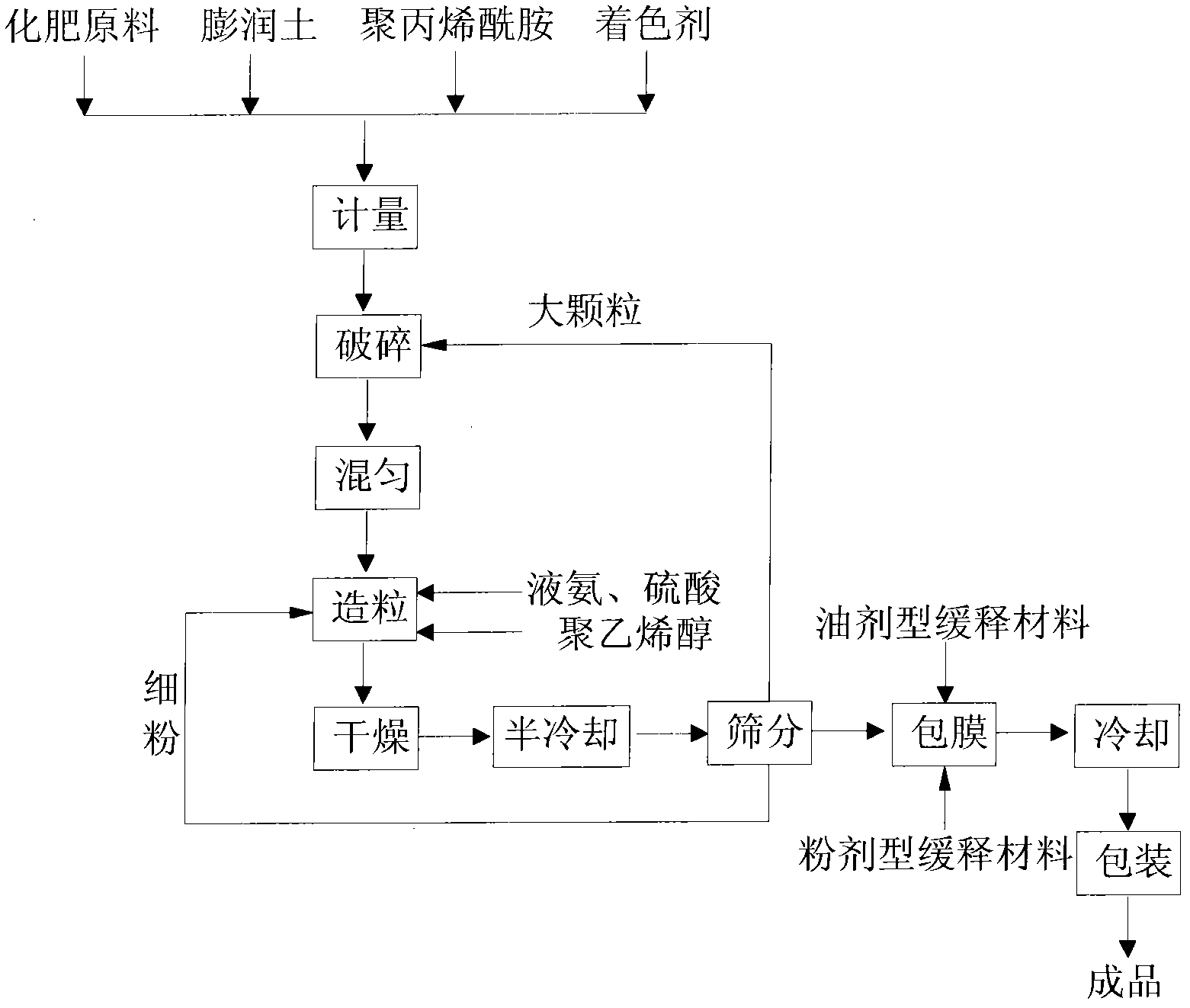

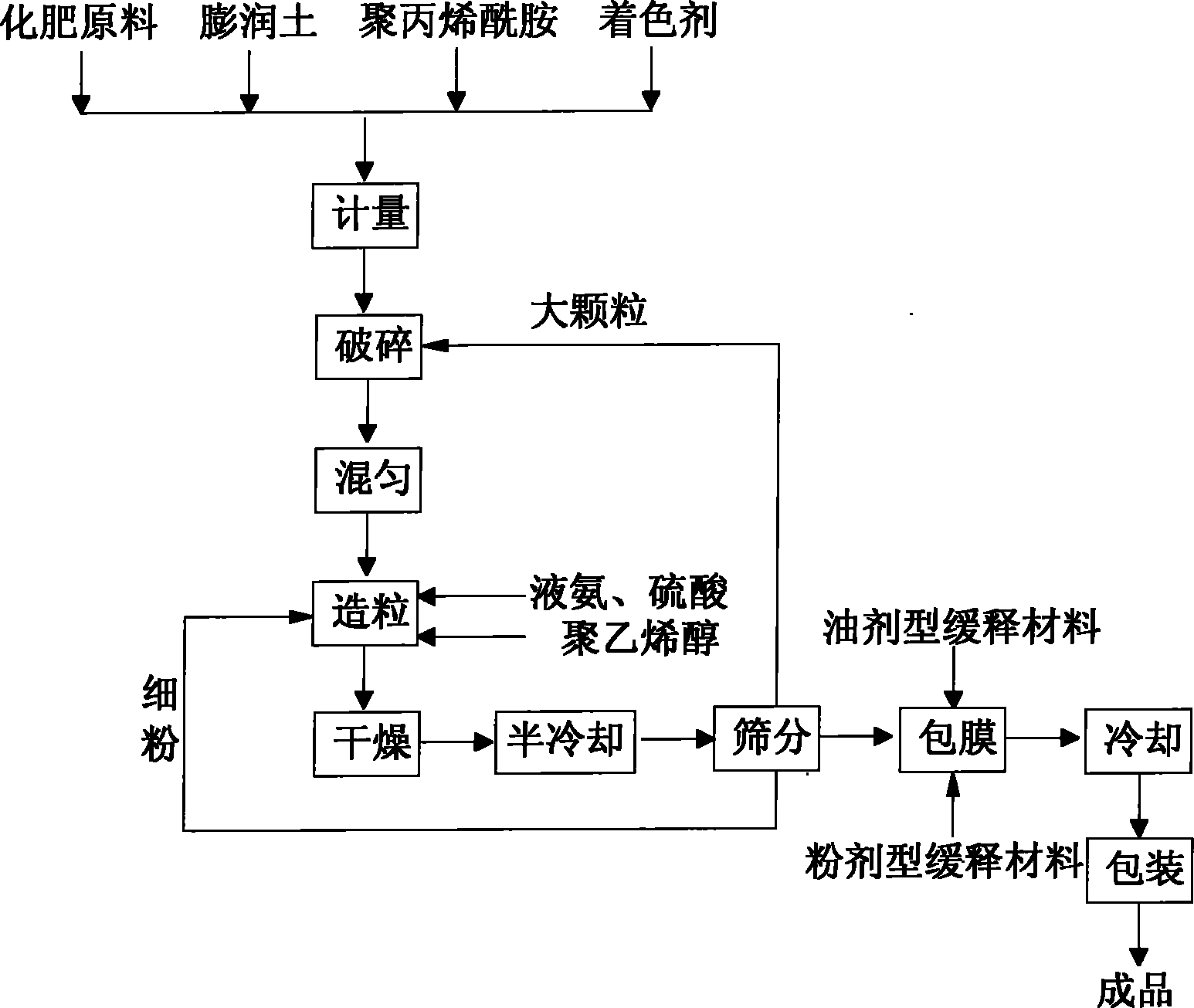

Method used

Image

Examples

Embodiment 1

[0031] Total nutrient (N+P 2 O 5 +K 2 O) ≥42%, the specification is 22-8-12 (chlorine) high-efficiency environmentally friendly slow-release compound fertilizer, the specific process steps are as follows:

[0032] (1) Weigh 18.73kg potassium chloride (including K 2 O-60.0%), 16.95kg monoammonium phosphate (containing N-11.0%, containing P 2 O 5 -44.0%), 10.70kg ammonium chloride (containing N-23.5%), 33.89kg urea (containing N-46.2%), 4.46kg bentonite, 0.27kg polyacrylamide, 0.02kg lemon yellow, crush and mix the above raw materials Evenly, the mixture is obtained and sent to the ammoniating drum granulator;

[0033] (2) Spray 2.41kg of liquid ammonia, 2.32kg of 60% dilute sulfuric acid, and 6.24kg of 3% polyvinyl alcohol aqueous solution on the above mixture in the granulator;

[0034] (3) Two-stage drying, semi-cooling and coarse and fine sieving are adopted. After sieving, particles with a particle size of 2.0-4.5mm enter the special coating machine, large particles larger than 4....

Embodiment 2

[0038] Total nutrient (N+P 2 O 5 +K 2 O) ≥42%, the specification is 16-10-16 (potassium sulfate type) high-efficiency environmentally friendly slow-release compound fertilizer. The specific process steps are as follows:

[0039] (1) Measure 29.58kg potassium sulfate (including K 2 O-50.0%), 21.30kg monoammonium phosphate (containing N-11.0%, containing P 2 O 5 -44.0%), 3.55kg ammonium sulfate (containing N-20.5%), 24.25kg urea (containing N-46.2%), 7.10kg bentonite, 0.06kg polyacrylamide, 0.03kg light fast yellow, crush and mix the above raw materials Evenly, the mixture is obtained and sent to the ammoniating drum granulator;

[0040] (2) Spray 2.07kg of liquid ammonia, 2.07kg of dilute sulfuric acid (60% by mass), and 7.10kg of polyvinyl alcohol aqueous solution (2% by mass) to the above mixture in the granulator;

[0041] (3) Two-stage drying, semi-cooling and coarse and fine sieving are adopted. After sieving, particles with a particle size of 2.0-4.5mm enter the special coating ...

Embodiment 3

[0045] Total nutrient (N+P 2 O 5 +K 2 O) ≥37%, the specification is 27-0-10 (chlorine) high-efficiency environmentally friendly slow-release compound fertilizer, the specific process steps are as follows:

[0046] (1) Measure 15.34kg potassium chloride (containing K2O-60.0%), 14.25kg ammonium chloride (containing N-23.5%), 47.13kg urea (containing N-46.2%), 9.86kg bentonite, 0.11kg polypropylene Amide, 0.04kg permanent red, crush and mix the above raw materials uniformly to obtain the mixed material, and send it to the ammoniating drum granulator;

[0047] (2) Spray 1.97kg of liquid ammonia, 2.19kg of dilute sulfuric acid (60% by mass) and 4.38kg of polyvinyl alcohol aqueous solution (4% by mass) to the above mixture in the granulator;

[0048] (3) Two-stage drying, semi-cooling and coarse and fine sieving are adopted. After sieving, particles with a particle size of 2.0-4.5mm enter the special coating machine, large particles larger than 4.5mm are returned to crush, and fine particl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com