Carbon/carbon composite material lifting appliance for high-temperature furnace

A carbon composite material, high temperature furnace technology, applied in the direction of load hanging components, transportation and packaging, can solve the problems of harsh working conditions and poor safety, achieve a wide range of applications, low manufacturing costs, and avoid harsh conditions in high temperature furnaces Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

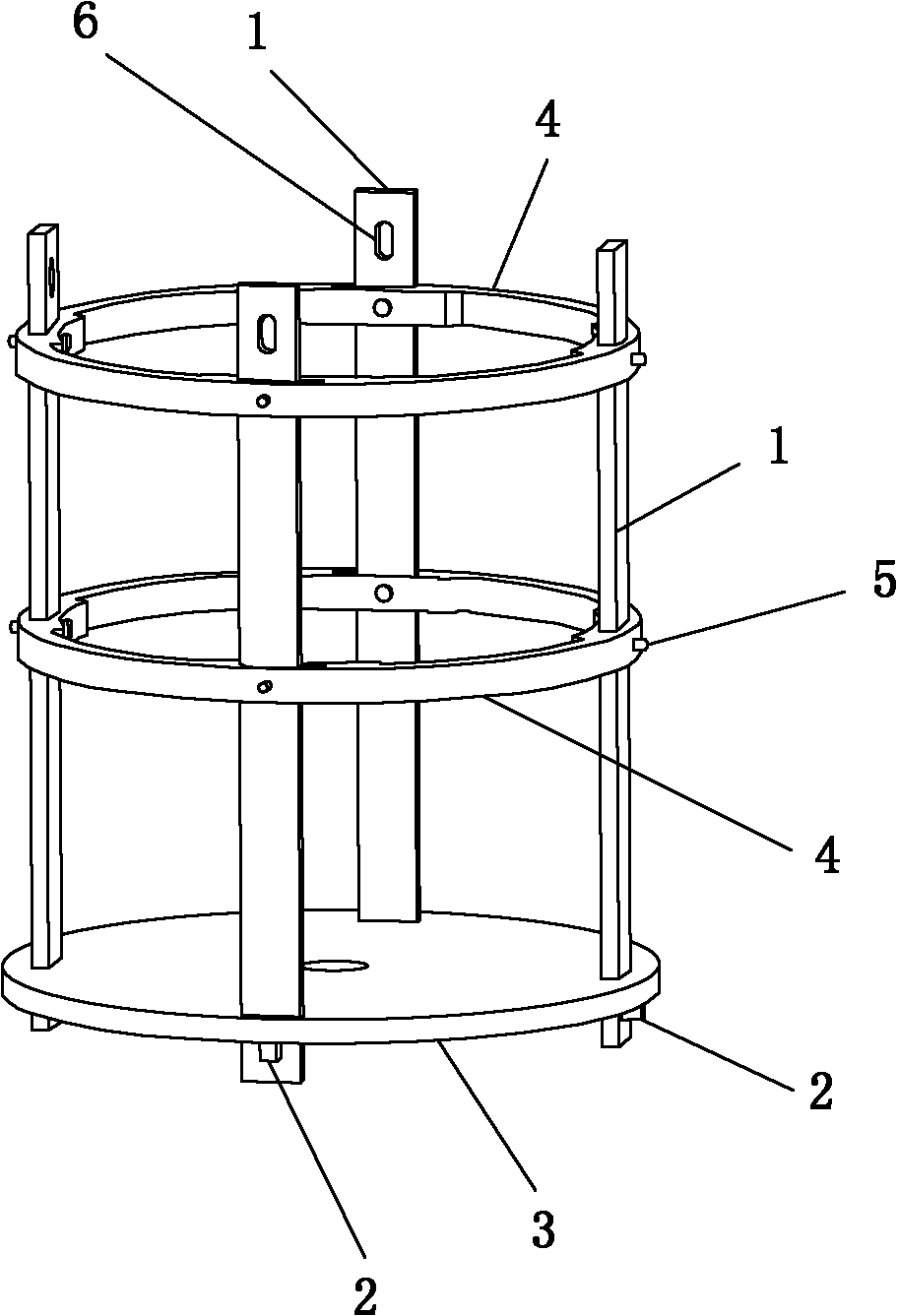

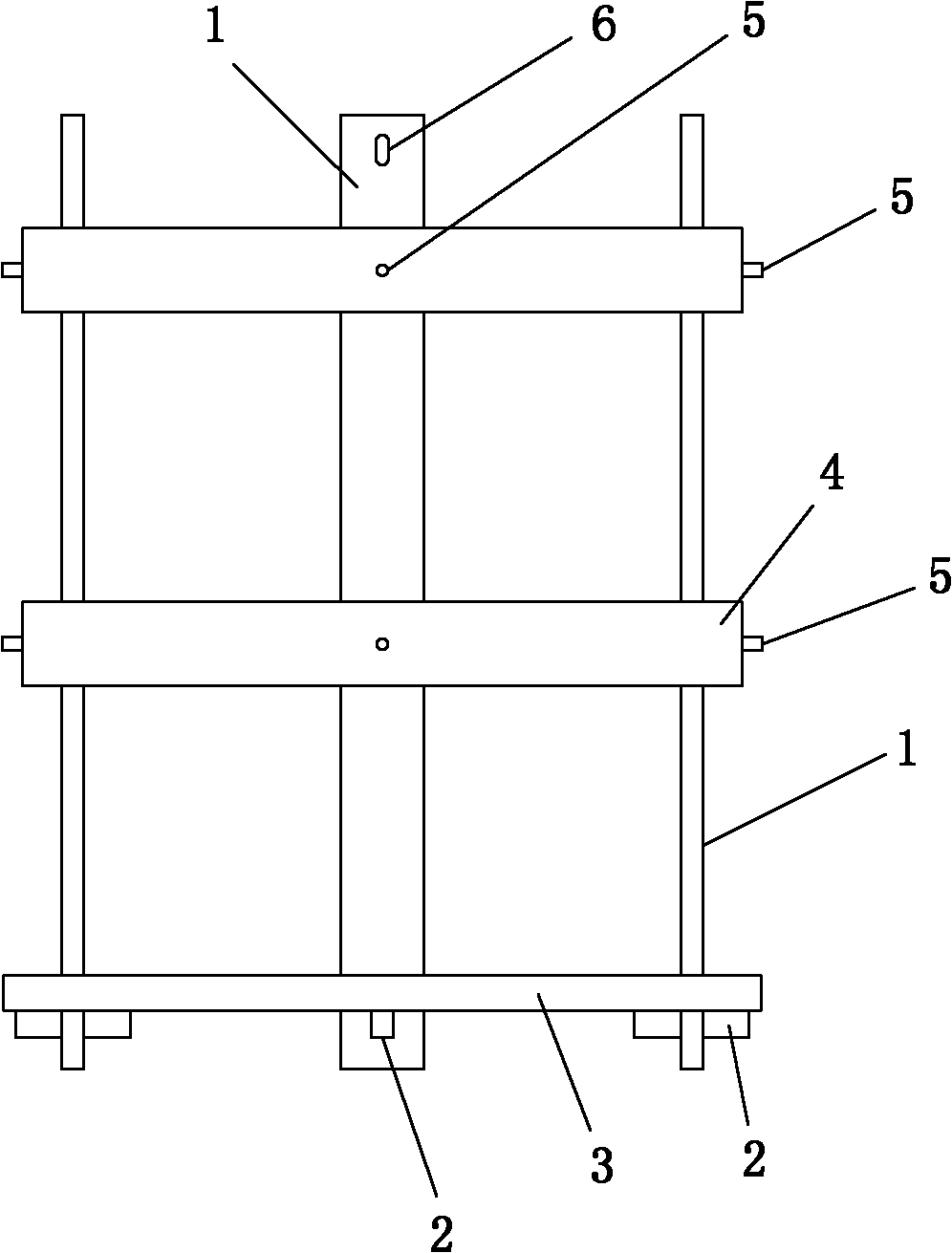

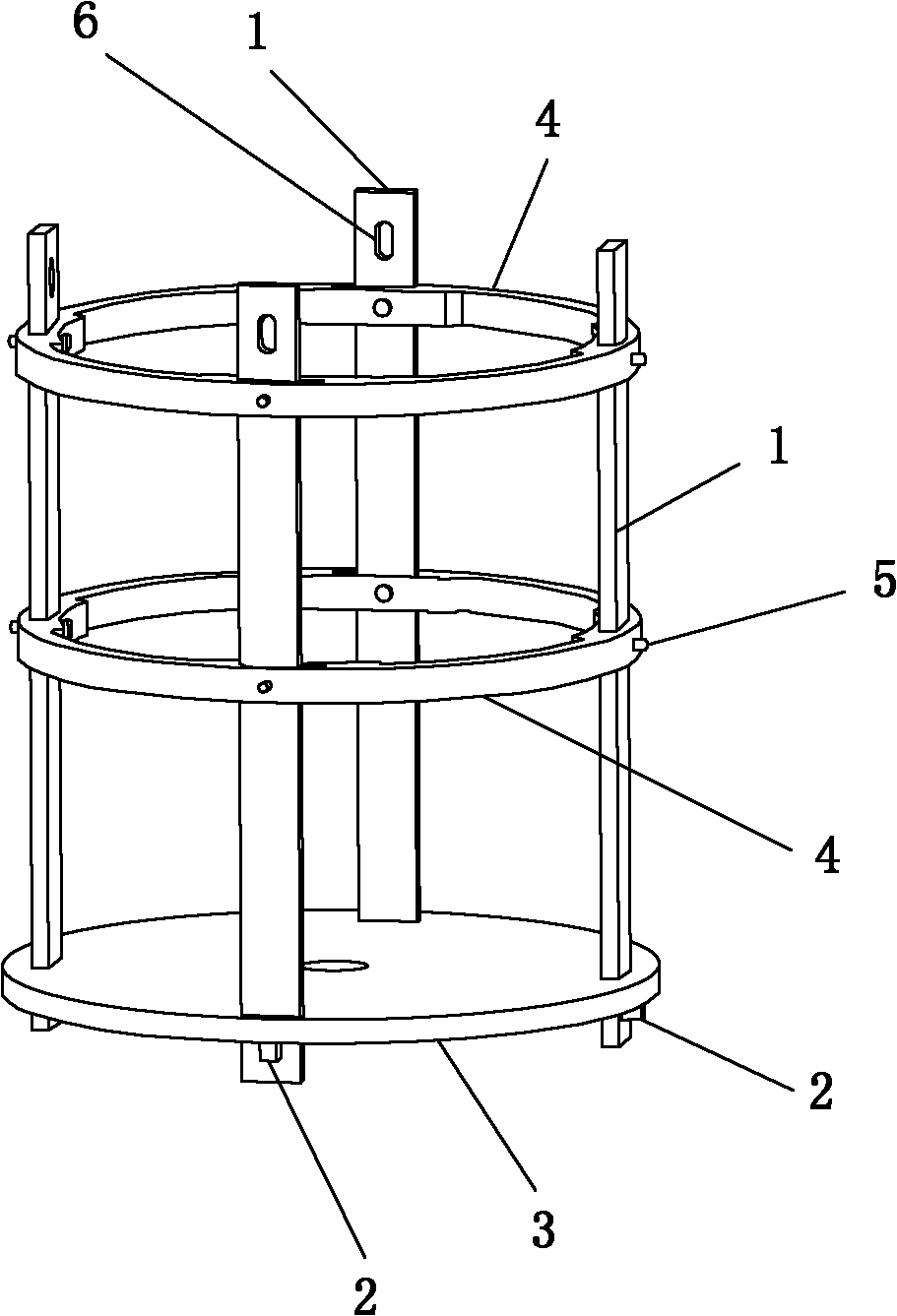

[0028] Such as figure 1 , figure 2 As shown, the present invention includes a load-bearing chassis 3 for containing processed products, a plurality of load-bearing suspenders 1 arranged vertically on the load-bearing chassis 3 evenly along the circumferential direction, and multiple channels for multiple An annular ring plate 4 that is fixed to the load-bearing suspenders 1 and is arranged horizontally. The suspenders 1 are fastened and connected by a fastening device 1, and the bottoms of the multiple load-bearing suspenders 1 are fixedly installed on the load-bearing chassis 3, and the load-bearing chassis 3 is correspondingly provided with a plurality of for the described The mounting holes for the load-bearing suspenders 1 are installed, and the load-bearing chassis 3 and the multiple load-bearing suspenders 1 are fastened and fixed by the fastening device 2. The structure and structure of the multiple load-bearing suspenders 1 All are the same size. The plurality of r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com