Multi-station mobile steam exhaust and dust removal method and device

A technology of dust removal device and steam exhaust, which is applied to cleaning methods and utensils, removal of smoke and dust, separation methods, etc., can solve problems such as single function, hidden safety hazards, affecting the sight of cranes, etc., and achieves a high degree of automation, compact structure, and dust removal effect. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

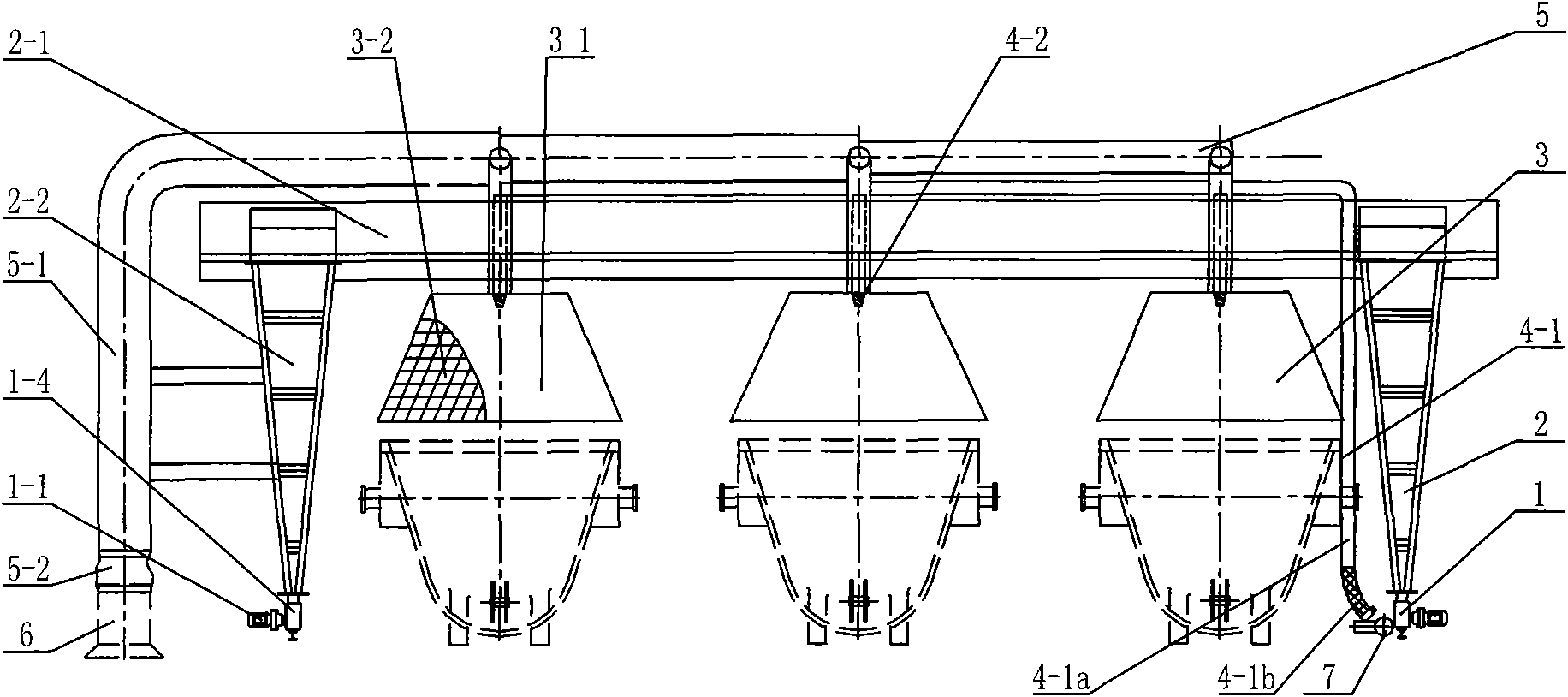

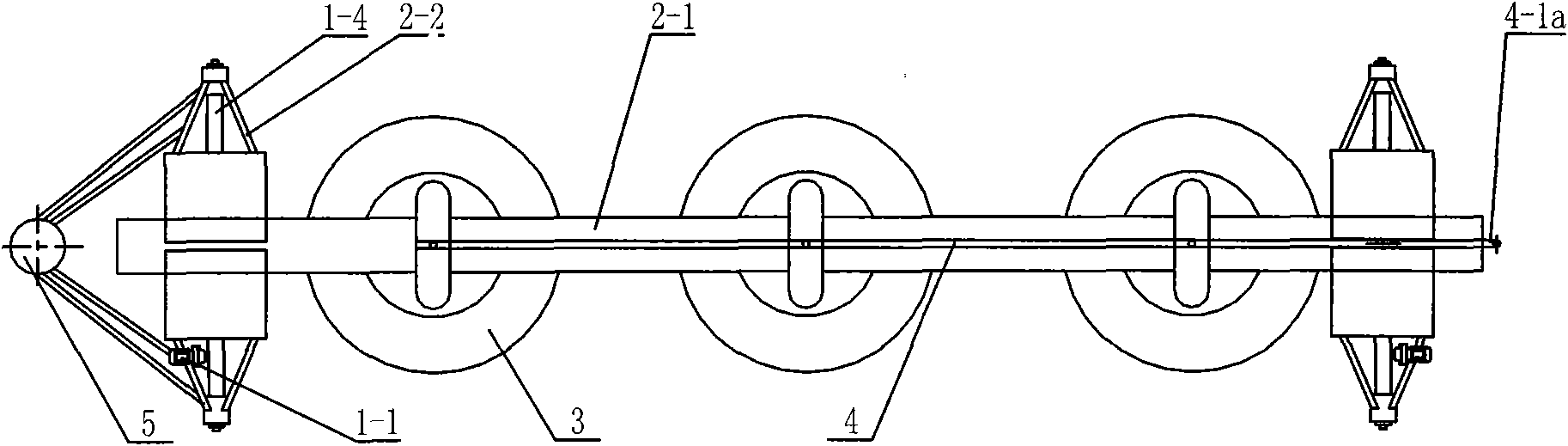

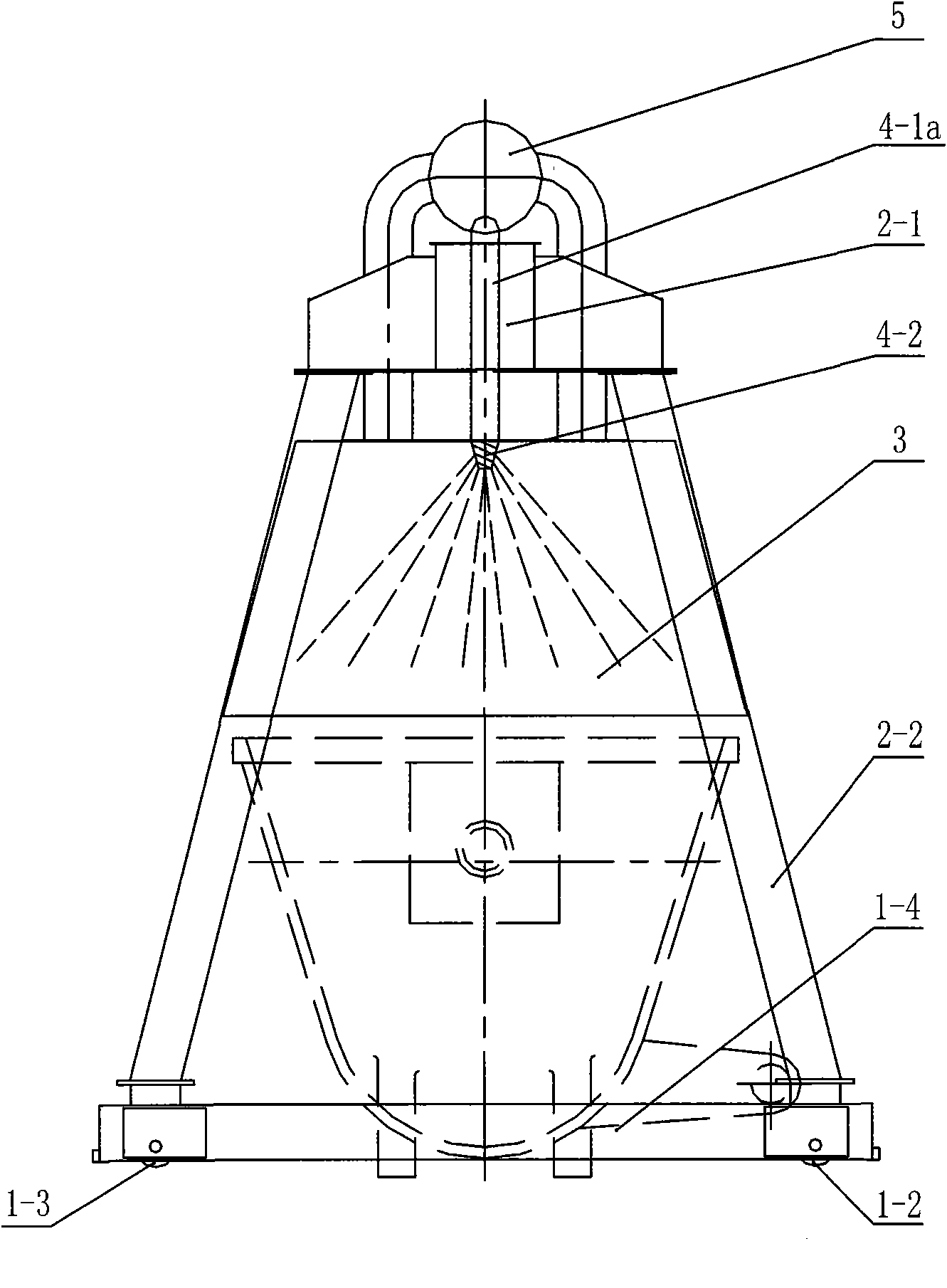

[0033] Embodiment: The present invention well solves the problem of dust removal in the process of hot metal pretreatment desulfurization slag treatment. It is an effective way to deal with desulfurization slag by spraying water in a tank to cool the desulfurization slag from hot metal pretreatment. In the past treatment process, when the cooling water is sprayed onto the surface of the molten iron pretreatment desulfurization slag, a large amount of water vapor and scrap steel chips will be generated; moreover, these water vapor and scrap steel chips are often suspended in the air. The employees in the workshop are often working in such a harsh environment, which has caused great hidden dangers to their health problems; at the same time, a large amount of water vapor has eroded the steel structure workshop. The invention well solves the problem of organized discharge of dust and steam in this process. In addition, the present invention can also be applied to water spray cool...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com