Method for treating desulfurization ash

A treatment method, desulfurization ash technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of excessive leaching toxicity, high loss on ignition, difficult process control, etc., and achieve the elimination of large fluctuations in components and effective Obvious, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

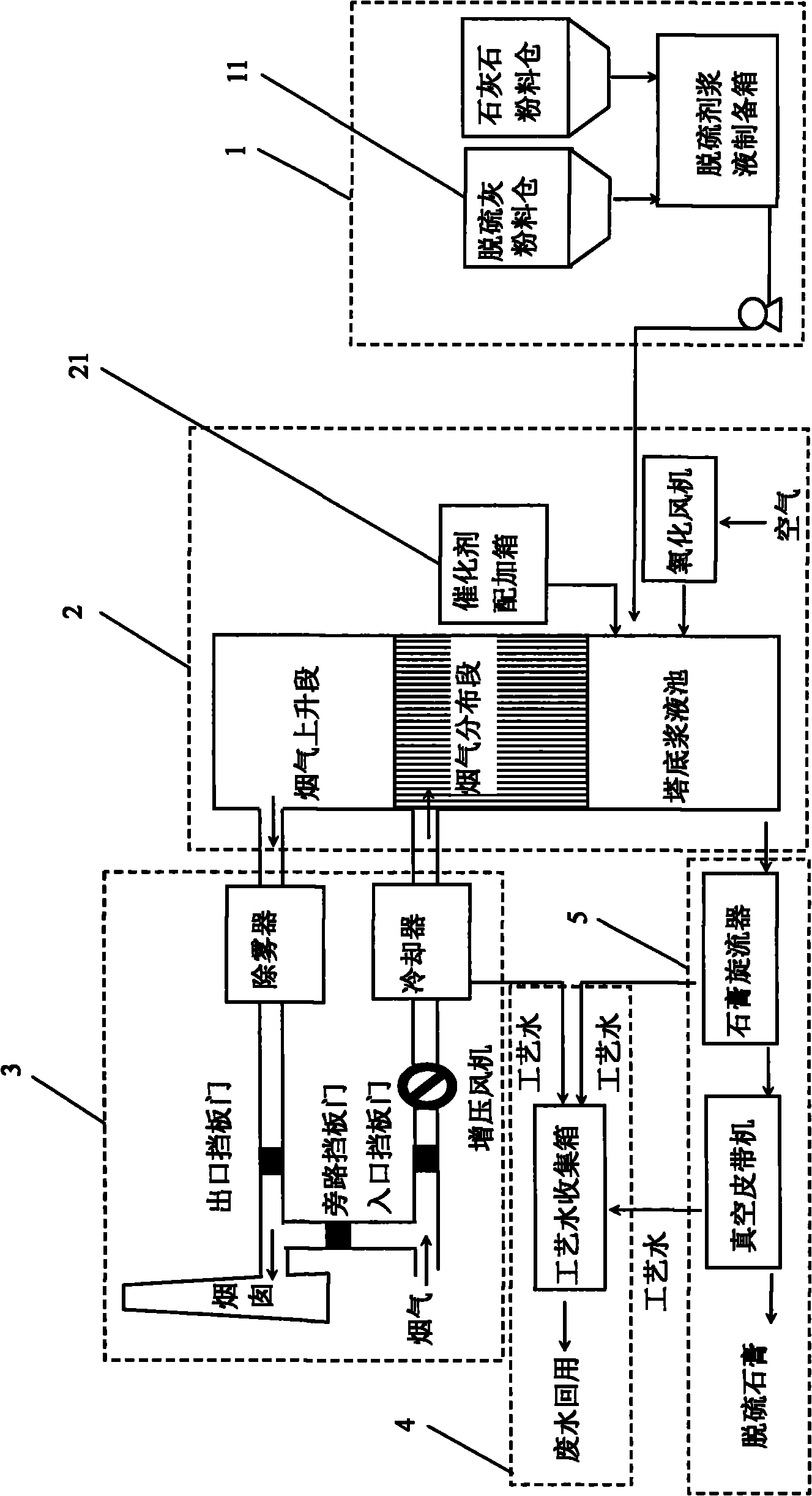

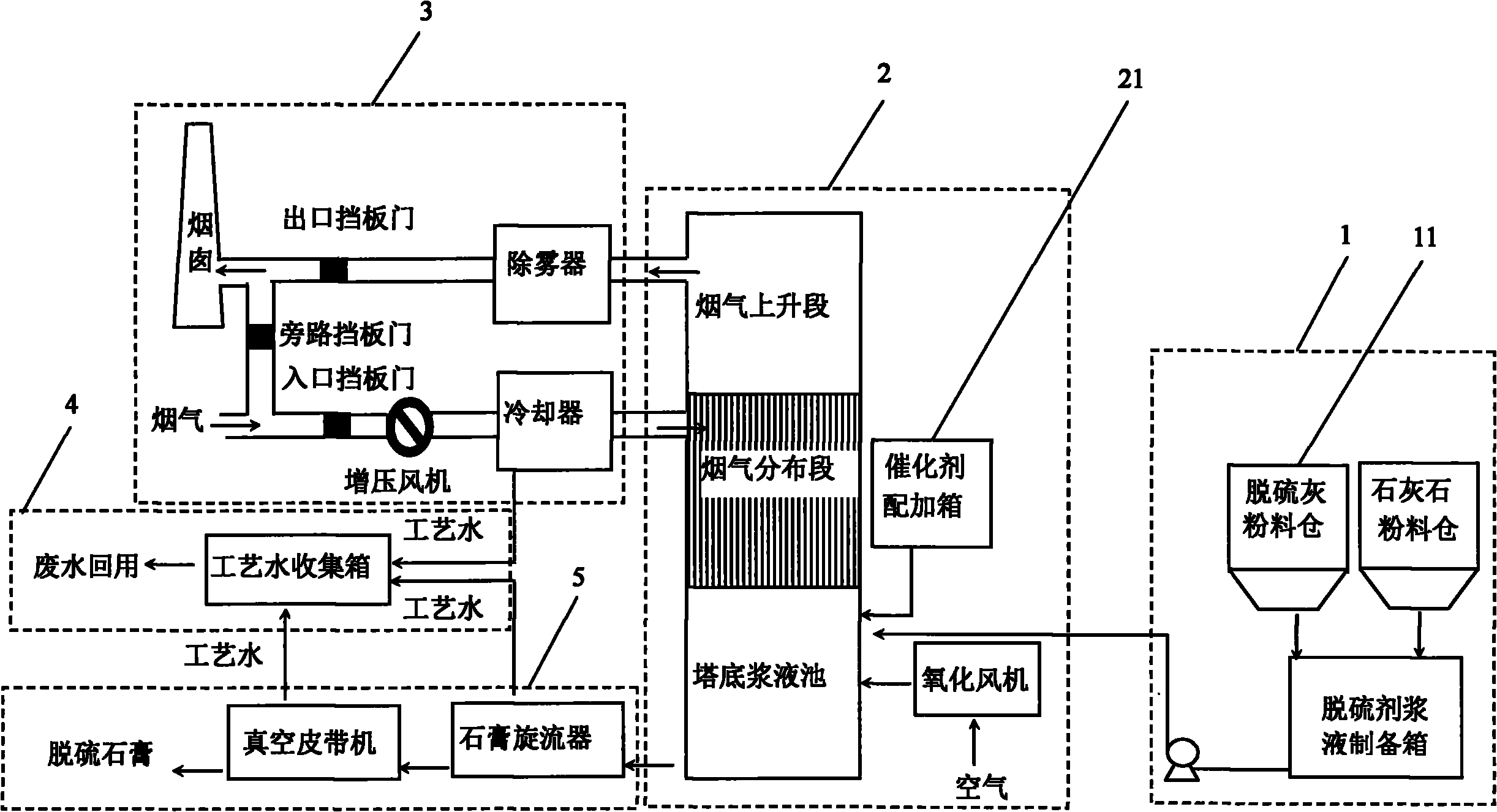

[0036] A kind of processing method of desulfurization ash, technological process is as follows figure 2shown. On the top of the desulfurizing agent slurry preparation box of the desulfurizing agent preparation system 1, there is a desulfurizing ash powder silo 11 and a limestone powder silo, and desulfurizing ash and limestone powder are used as raw materials for the desulfurizing agent, and the desulfurizing ash is obtained from a circulating fluidized bed dry process Flue gas desulfurization process, where CaSO 4 ·H 2 O mass fraction is 6.7%, CaSO 3 1 / 2H 2 O mass fraction is 59.6%, f-CaO mass fraction is 14.3%, Ca(OH) 2 The mass fraction is 9.5%, SiO 2 The mass fraction is 6.2%, Al 2 o 3 Mass fraction is 1.1%, MgO mass fraction is 0.5%, Fe 2 o 3 The mass fraction is 0.4%, where CaSO 3 1 / 2H 2 O, CaCO 3 , f-CaO and Ca(OH) 2 The total mass fraction of the four substances is 90.1%. The desulfurized ash and limestone powder are mixed according to the mass fraction r...

Embodiment 2

[0038] A kind of processing method of desulfurization ash, technological process is as follows figure 2 shown. On the top of the desulfurizing agent slurry preparation box of the desulfurizing agent preparation system 1, there is a desulfurizing ash powder silo 11 and a limestone powder silo. Desulfurizing ash and limestone powder are used as raw materials for the desulfurizing agent. The desulfurizing ash is taken from the furnace and sprayed with calcium oxide. Activation of semi-dry desulfurization process, where CaSO 4 ·H 2 O mass fraction is 21.5%, CaSO 3 1 / 2H 2 O mass fraction is 45.5%, f-CaO mass fraction is 10.4%, Ca(OH) 2 The mass fraction is 8.5%, SiO 2 The mass fraction is 3.1%, Al 2 o 3 Mass fraction is 0.8%, MgO mass fraction is 0.2%, Fe 2 o 3 The mass fraction is 0.1%, where CaSO 3 1 / 2H 2 O, CaCO 3 , f-CaO and Ca(OH) 2 The total mass fraction of the four substances is 64.4%. The desulfurized ash and limestone powder are mixed according to the mass f...

Embodiment 3

[0040] A kind of processing method of desulfurization ash, technological process is as follows figure 2 shown. On the top of the desulfurizing agent slurry preparation box of the desulfurizing agent preparation system 1, there is a desulfurizing ash powder silo 11 and a limestone powder silo. Desulfurizing ash and limestone powder are used as raw materials for the desulfurizing agent. The desulfurizing ash is obtained from limestone flue gas purification semi-dry desulfurization process, where CaSO 4 ·H 2 O mass fraction is 22.2%, CaSO 3 1 / 2H 2 O mass fraction is 45.8%, f-CaO is 8.5%, Ca(OH) 2 The mass fraction is 9.5%, SiO 2 The mass fraction is 3.1%, Al 2 o 3 Mass fraction is 0.8%, MgO mass fraction is 0.2%, Fe 2 o 3 The mass fraction is 0.1%, where CaSO 3 1 / 2H 2 O, CaCO 3 , f-CaO and Ca(OH) 2 The total mass fraction of the four substances is 63.8%. The desulfurized ash and limestone powder are mixed according to the mass fraction ratio of 1:4, mixed into the d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com