Method for preparing freeze-dried pineapple

A technology for pineapple, freeze-vacuum drying, applied in the field of food processing, can solve the problems of damage to color, aroma and nutrients, product shrinkage, and long heating time of pineapple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0009] Select 600kg of pineapple that is disease-free, non-rotten, and seven-ripe. Use a knife to cut off the head and tail of the pineapple, grade it according to the size of the fruit, peel off the skin with a knife, pull out the pineapple thorns, and then wash the pineapple meat twice with running drinking water. More than once, wash off the debris, then cut the pineapple into slices with a thickness of 5mm; then put the pineapple slices in hot water at 95°C for 2 minutes, cool them quickly with water, drain until the water drips continuously, and put them on a plate , and then freeze the pineapple slices to -30°C, put the frozen pineapple slices into the drying bin of a freeze-vacuum dryer for drying treatment, and then obtain a freeze-dried pineapple product with a water content of 5%. See Table 1 for parameter control.

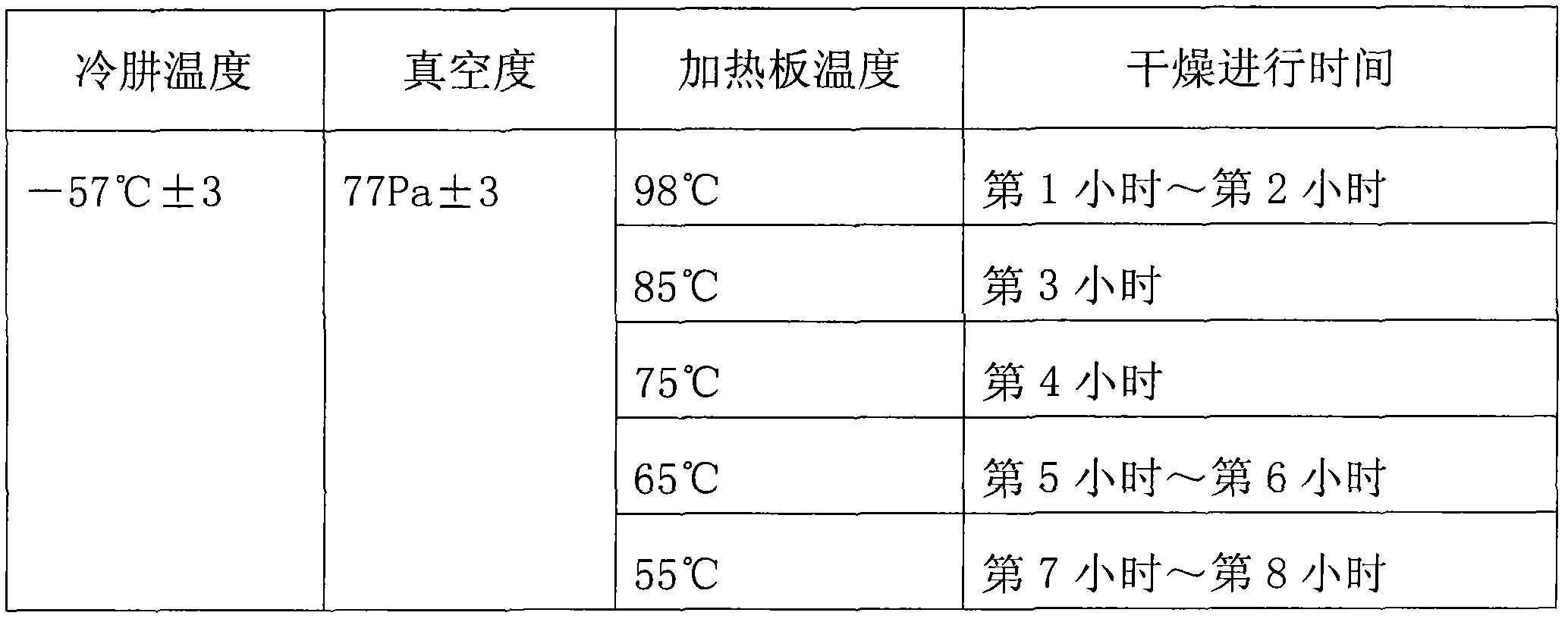

[0010] Table 1. Parameter control in the freeze vacuum dryer

[0011]

Embodiment 2

[0013] Select 800kg of pineapple with no disease, no rot and deterioration, and half mature, cut off the head and tail of the pineapple with a knife, grade according to the size of the fruit diameter, peel off the skin with a knife, pull out the pineapple thorns, and then wash the pineapple flesh with running drinking water More than two times, wash the debris, cut into slices with a thickness of 7mm; then put the pineapple slices in hot water at 99°C for 6 minutes, cool them quickly with water, drain until the water drips continuously, put them on a plate, and then Freeze the pineapple slices to -48°C, put the frozen pineapple slices into the drying chamber of the freeze-vacuum dryer for drying treatment, and then obtain the freeze-dried pineapple finished product with a water content of 3%. The parameters in the freeze-vacuum dryer are controlled See Table 2.

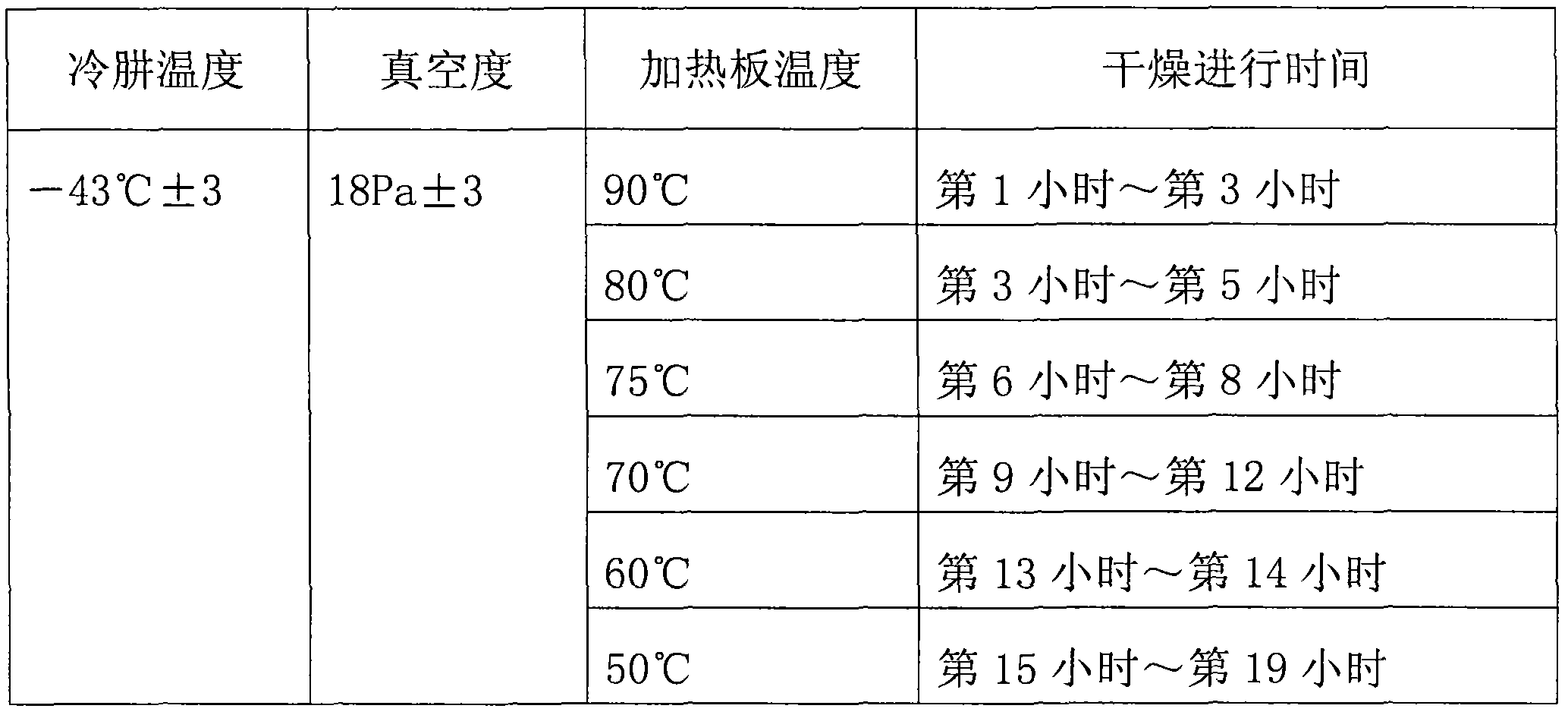

[0014] Table 2. Parameter Control in Freeze Vacuum Dryer Parameter Control in Freeze Vacuum Dryer

[0015]

Embodiment 3

[0017] Select 1,000kg of pineapple that is disease-free, non-rotten, and nearly mature, cut off the head and tail of the pineapple with a knife, grade it according to the size of the fruit, peel off the skin with a knife, pull out the pineapple thorns, and then wash the pineapple flesh with running drinking water More than two times, wash the debris, cut into cubes of 7×7×7mm; then put the diced pineapple in hot water at 97°C for 4 minutes, cool it quickly, drain the water, put it on a plate, and put the pineapple Freeze the diced pineapple to -40°C, put the frozen diced pineapple into the drying chamber of the freeze-vacuum dryer for drying treatment, and then obtain the finished product of freeze-dried pineapple with a water content of 4%. The parameters in the freeze-vacuum dryer are controlled in the table 3.

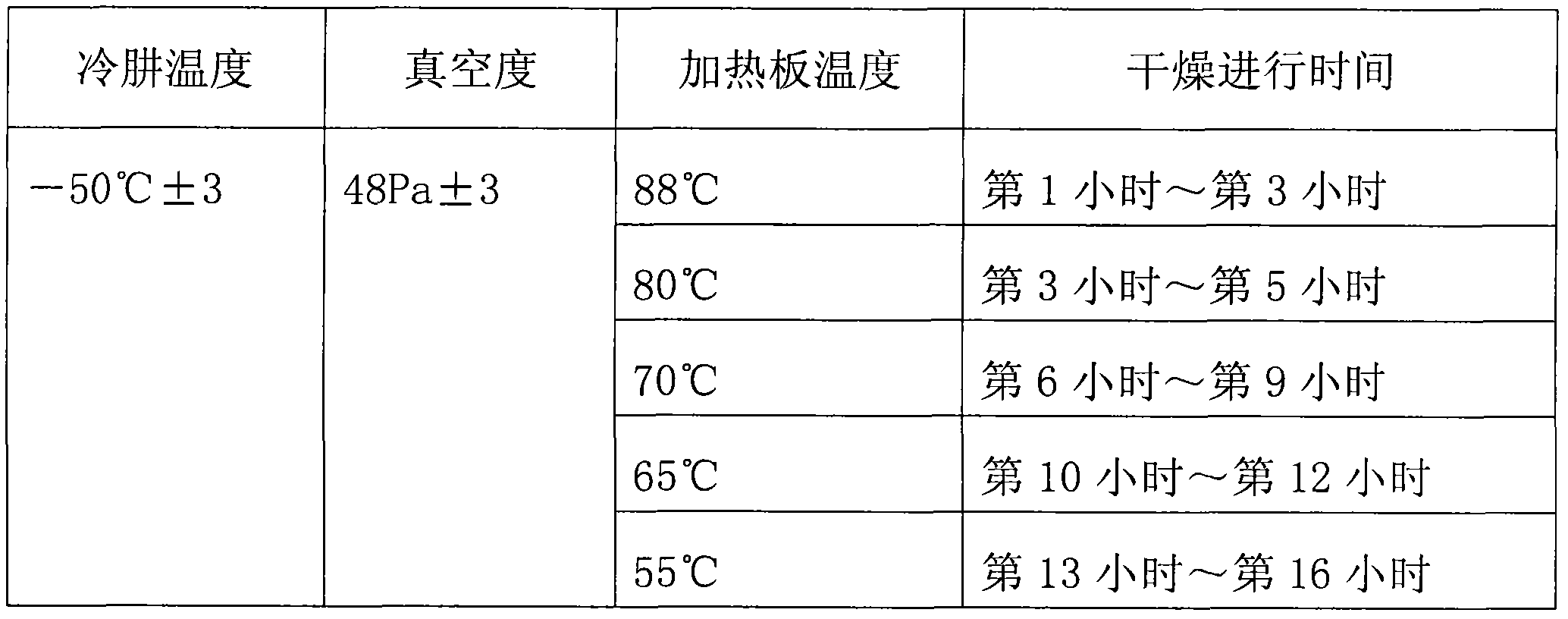

[0018] Table 3. Parameter control in the freeze vacuum dryer

[0019]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com