Device for production of nanofibres through electrostatic spinning of polymer composition

A nanofiber and polymer technology, applied in fiber processing, textiles and papermaking, filament/thread forming, etc., can solve problems such as time delay, inability to place electrical devices, inability to monitor spinning space conditions, etc., to prevent burning or even Explosion, increased safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

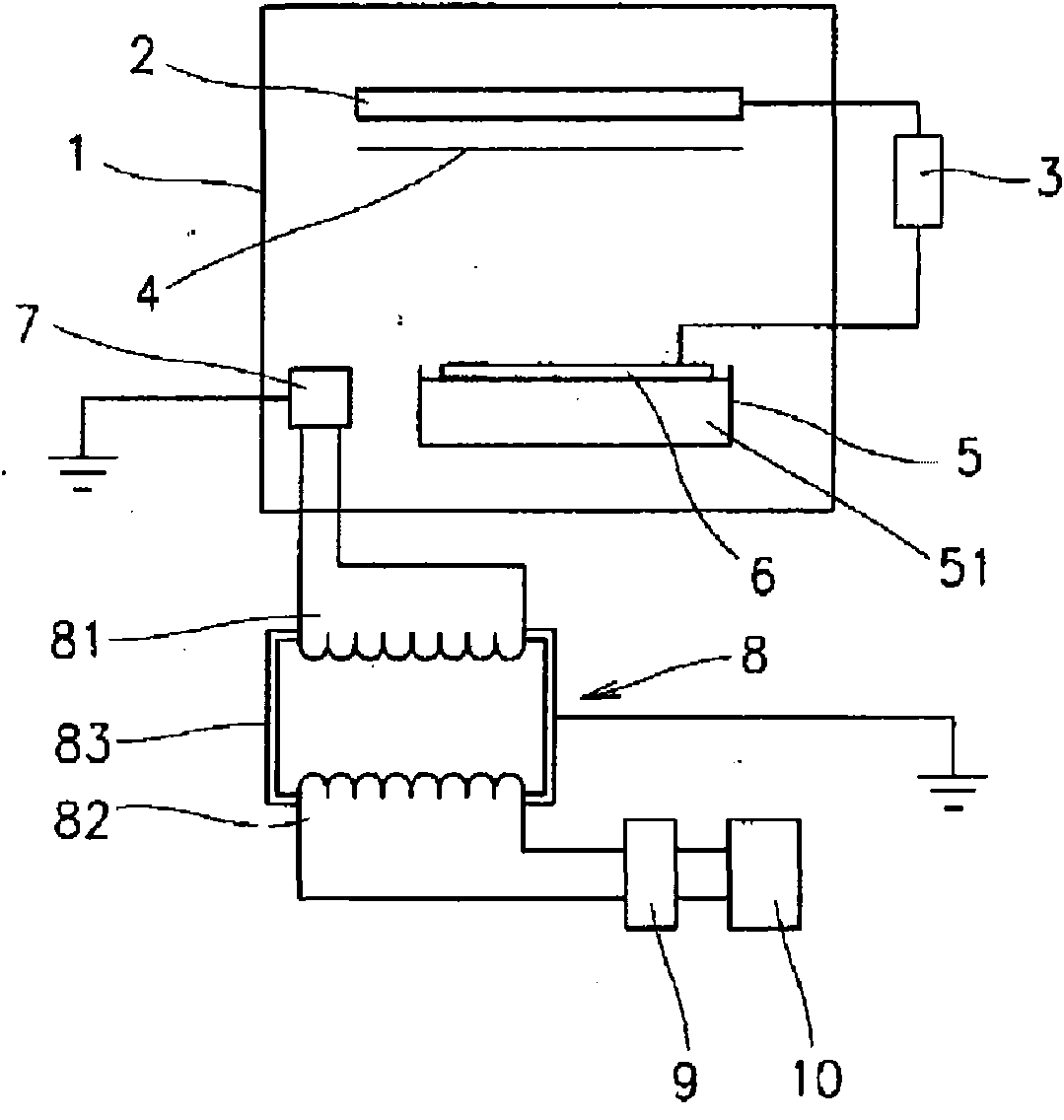

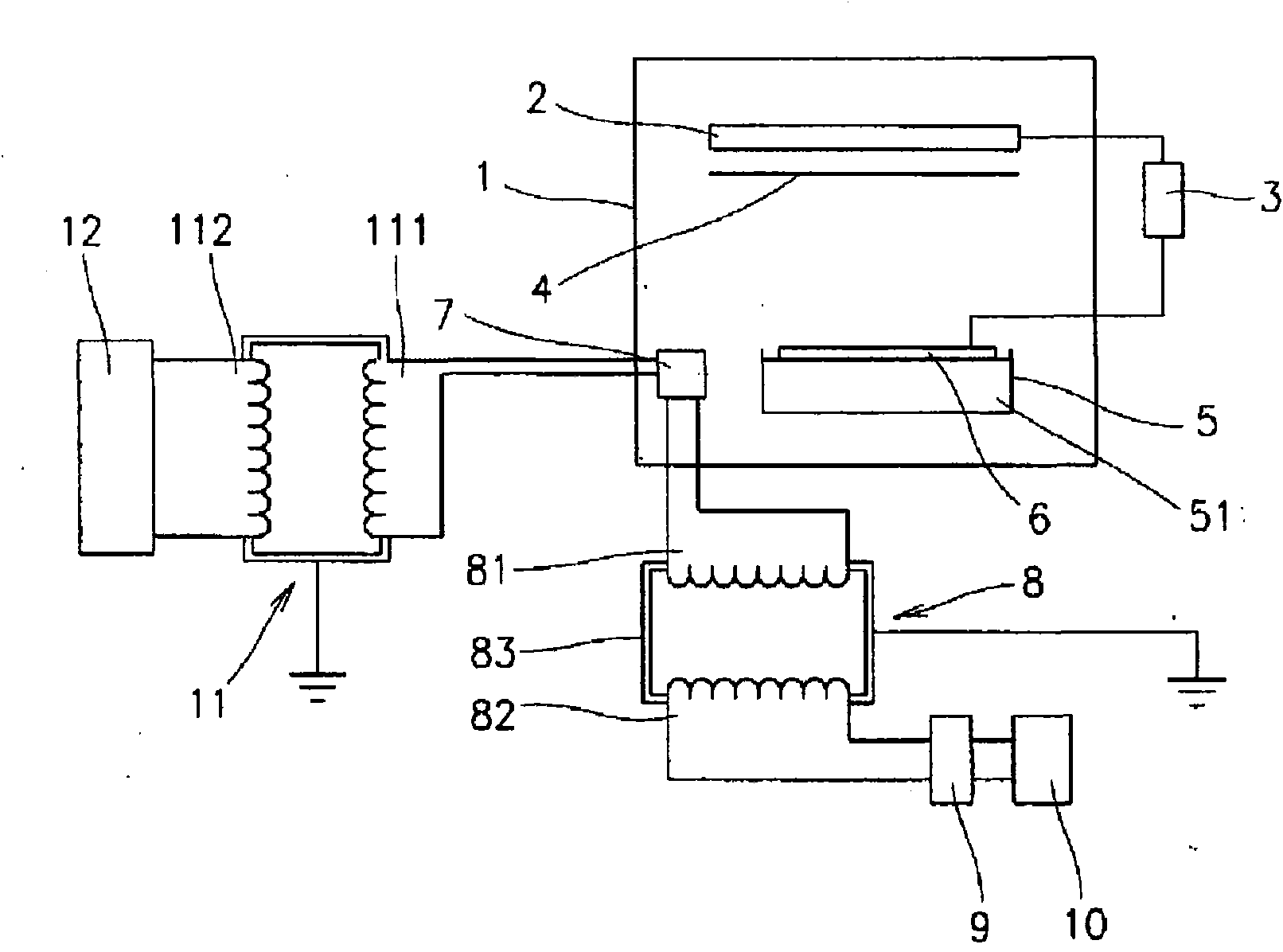

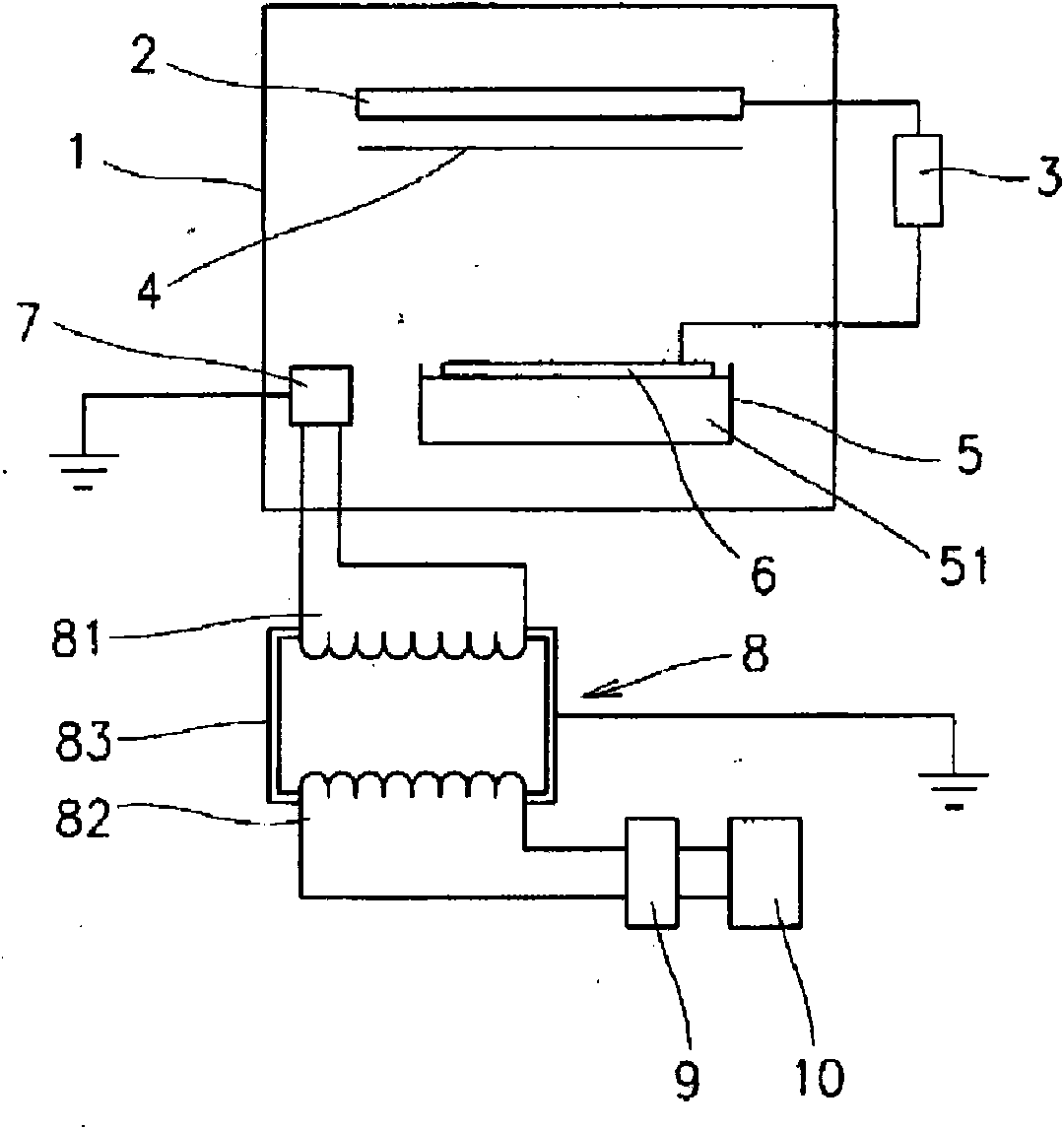

[0034] will be based on figure 1 The example of an embodiment schematically shown in the present invention describes the device and its principle for producing nanofibers by electrospinning of a liquid matrix. In order to increase the clarity and conciseness of the drawings, only some elements of the device are shown in a simplified manner regardless of their real structure or proportions, which are not essential to the understanding of the principles of the invention and whose structure or mutual arrangement is essential to those skilled in the art. Other elements that are obvious to a person are not shown at all.

[0035] The device for electrospinning a polymer matrix comprises a spinning chamber 1 defining a spinning space, a collecting electrode 2 is arranged on the upper part of the spinning chamber 1, and the collecting electrode 2 is connected to a One pole of the high DC high voltage source 3 . The shown collection electrode 2 is formed by a metal plate, however in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com