Analysis method for reaction products of preparing ethylene glycol by ethylene oxide catalytic hydration

A technology of ethylene oxide catalyzing water and reaction products, which is applied in the direction of analyzing materials, material separation, and measuring devices, can solve problems such as heavy peaks in chromatographic peaks, poor repeatability of analysis results, etc., and achieve high analysis accuracy and precision, Eliminates the effect of large volume expansion and good technical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

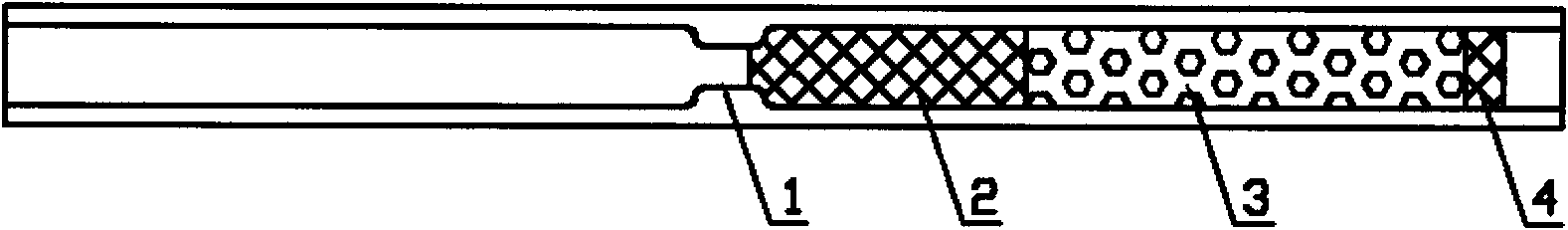

[0018] Preparation of filled Tenax TA glass liners:

[0019] The liner adopts the split / splitless glass liner from Agilent, which has a partition in the middle and a tapered bottom. Fill the bottom of the liner with silanized glass wool 2-3 mm, and after flattening, fill Tenax TA (60-80 mesh) 21-22 mm on the top, then fill the glass wool to the interrupted part of the liner, and flatten it.

[0020] Ageing:

[0021] Put the glass liner loaded with Tenax TA into the gas chromatograph inlet, use high-purity nitrogen as the carrier gas, set the chromatographic conditions as follows: detector temperature 250°C, column front pressure 20psi, carrier gas linear velocity 37cm s -1 , split ratio 30:1, gas 32mL / min, assisted gas 350mL / min, auxiliary gas 25mL / min, oven temperature 160°C, gasification chamber temperature at room temperature, after 20 minutes of stabilization, set the gasification chamber temperature to 250 ℃, using temperature programming, the initial temperature is 160...

Embodiment 2

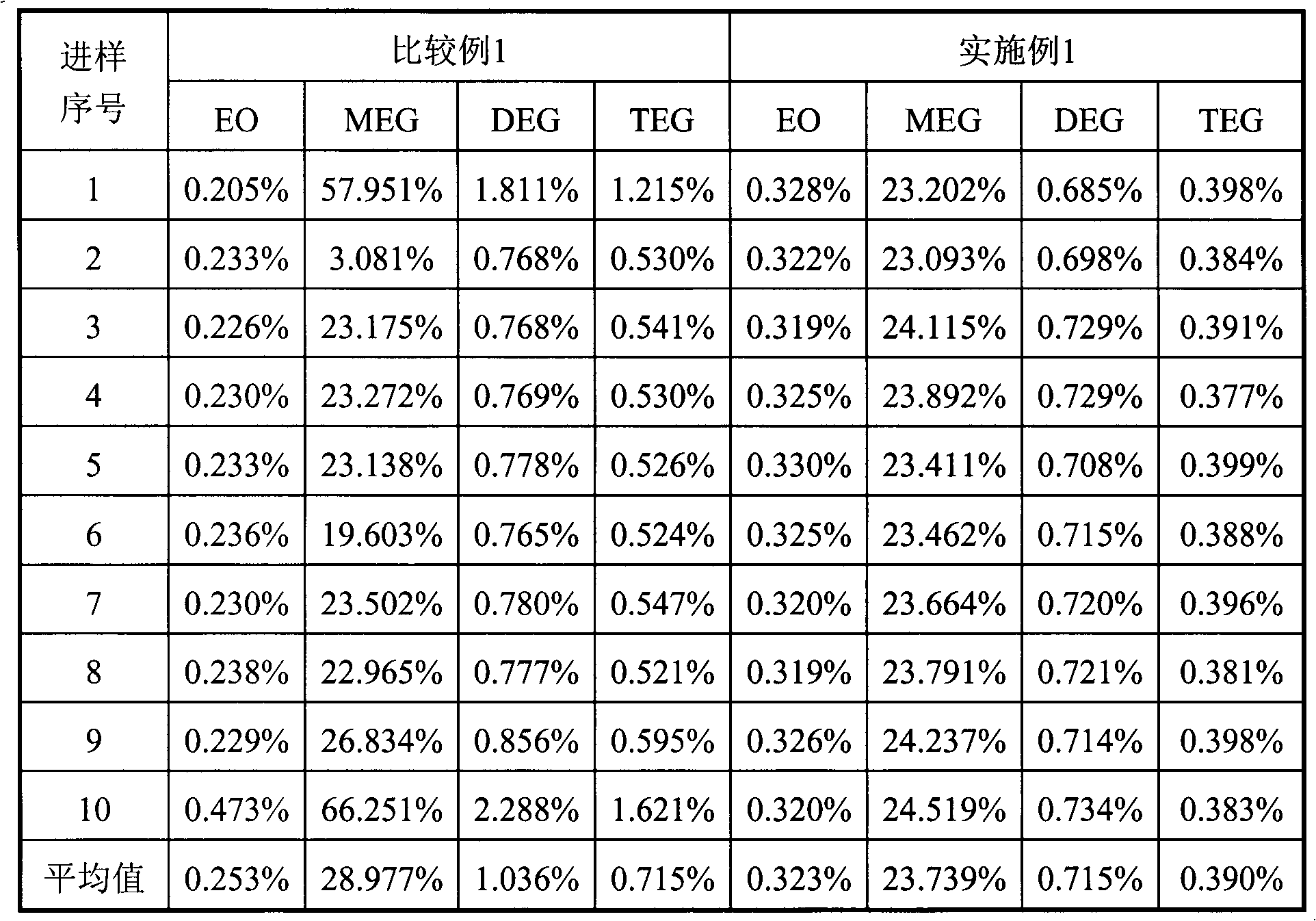

[0039] After the completion of Example 1, the conditions were unchanged (the 1mL syringe was the corresponding syringe in Example 1), about 3mL samples were taken from the ethylene glycol catalytic hydration process device of ethylene oxide with a 5mL sampling bottle, and 1mL Accurately extract 1mL sample with 1mL internal standard 6% ethylene glycol butyl ether aqueous solution and mix evenly, use 1 μ L microsampler (needle length is identical with embodiment 1), get 0.2 μ L and inject gas chromatographic inlet and analyze, analyze The results are shown in Table 4 (the FID detector does not have a peak for water).

[0040] Table 4

[0041] keep time

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com