Method for preventing peritectic steel continuous casting blank from generating cracks

A technology for continuous casting slabs and cracks, which is applied in the field of preventing cracks in peritectic steel continuous casting slabs. It can solve the problems of deteriorating casting slab lubrication, reducing casting speed, and difficult gaps, so as to improve the quality of casting slabs and increase production efficiency. , the effect of reducing the amount of cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

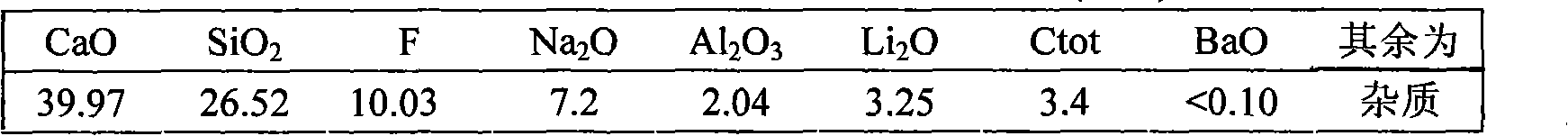

[0028] The composition and physical properties of the mold flux used in this example are shown in Table 1 and Table 2.

[0029] Table 1 Example 1 mold flux composition and physical properties (wt%)

[0030]

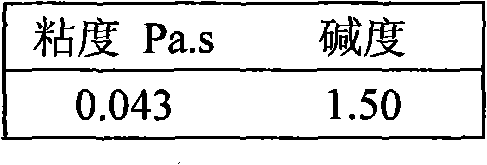

[0031] Table 2 Physical properties of mold flux in Example 1

[0032]

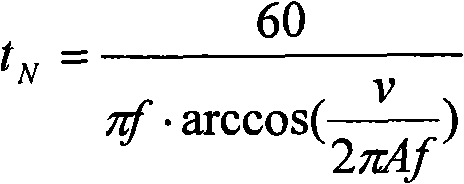

[0033] Process parameters: casting speed: 2.2m / min; slab size: 1050*135mm; water flow density at the wide side of the mold 4300l / min; water flow density at the narrow side of the mold 330l / min; the mold adopts sinusoidal vibration: the amplitude is 6.5mm, Vibration frequency is 196min -1 , Negative slip time 0.075s.

[0034] No obvious cracks were found on the surface of the slab produced by the continuous casting method of Example 1.

Embodiment 2

[0036] The composition and physical properties of the mold flux used in this example are shown in Table 3 and Table 4.

[0037] Table 3 Example 2 mold flux composition (wt%)

[0038]

[0039] Table 4 Physical properties of mold flux in Example 2

[0040]

[0041] Process parameters: casting speed: 2.1m / min; slab size: 1050*135mm; water flow density on the wide side of the mold 4400l / min; water flow density on the narrow side of the mold 340l / min; the mold adopts sinusoidal vibration: the amplitude is 7.4mm, Vibration frequency is 189min -1 , Negative slip time 0.16s.

[0042] No obvious cracks were found on the surface of the slab produced by the continuous casting method of Example 2.

Embodiment 3

[0044] The composition and physical properties of the mold flux used in this example are shown in Table 5 and Table 6.

[0045] Table 5 Example 3 mold flux composition (wt%)

[0046]

[0047] Table 6 Physical properties of mold flux in Example 3

[0048]

[0049] Process parameters: casting speed: 2.4m / min; slab size: 1050*135mm; water flow density at the wide side of the mold 4500l / min; water flow density at the narrow side of the mold 350l / min; the mold adopts sinusoidal vibration: the amplitude is 8.0mm, Vibration frequency is 150min -1 , Negative slip time 0.10s.

[0050] No obvious cracks were found on the surface of the slab produced by the continuous casting method of Example 3.

[0051] The off-line cleaning rate of peritectic steel in each embodiment is shown in Table 7, which is reduced from the original 3% to about 1%.

[0052] Table 7 embodiment off-line cleaning rate

[0053]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com