Rotary compressor

A rotary compressor and compressor technology, applied in the field of compressors, can solve the problems of reducing compressor life and increasing wear, and achieve the effect of reducing oil output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

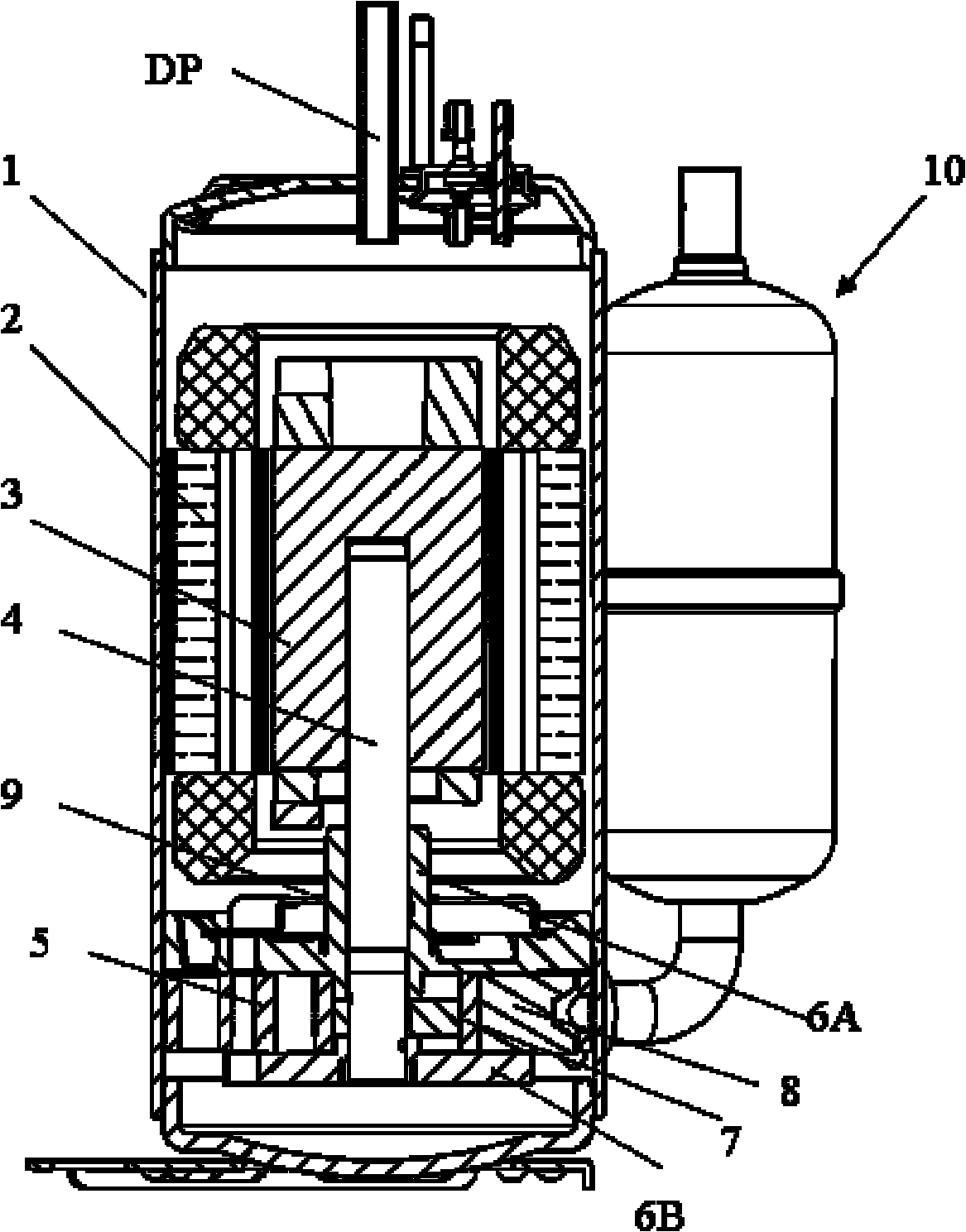

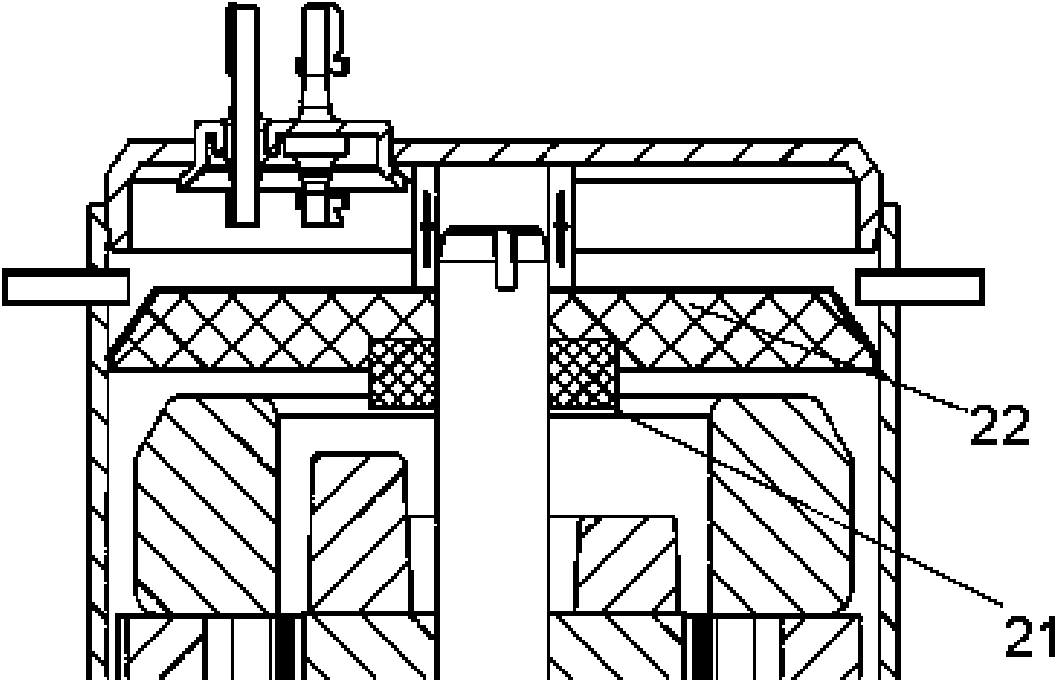

[0018] The structure of the rotary compressor of the present invention will be described in detail below with reference to the accompanying drawings.

[0019] Such as figure 2 and image 3 As shown, the rotary compressor of the present invention includes: a housing 31 , a compressor crankshaft 20 disposed in the housing 31 and having an eccentric portion, a mechanical structure, a motor drive and a compressor structure. Wherein, the motor driving part includes: a motor stator 32 and a motor rotor 23 arranged inside the housing 31, and the center of the motor rotor 23 is press-fitted and installed on the crankshaft 20; the compression structure part includes: The circular cylinder 35 fixedly arranged on the inner peripheral surface of the housing 31, the roller ring 37 which is arranged on the eccentric part of the crankshaft 34 and rotates eccentrically in the cylinder 35 under the action of the crankshaft 34, and one end which is crimped on the roller ring 37 On the outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com