Food slicing machine

A technology for slicer and food, applied in metal processing and other directions, can solve the problems of high cost, large volume, complex mechanical structure, etc., and achieve the effect of avoiding mechanical design, simple mechanical structure and realizing miniaturization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

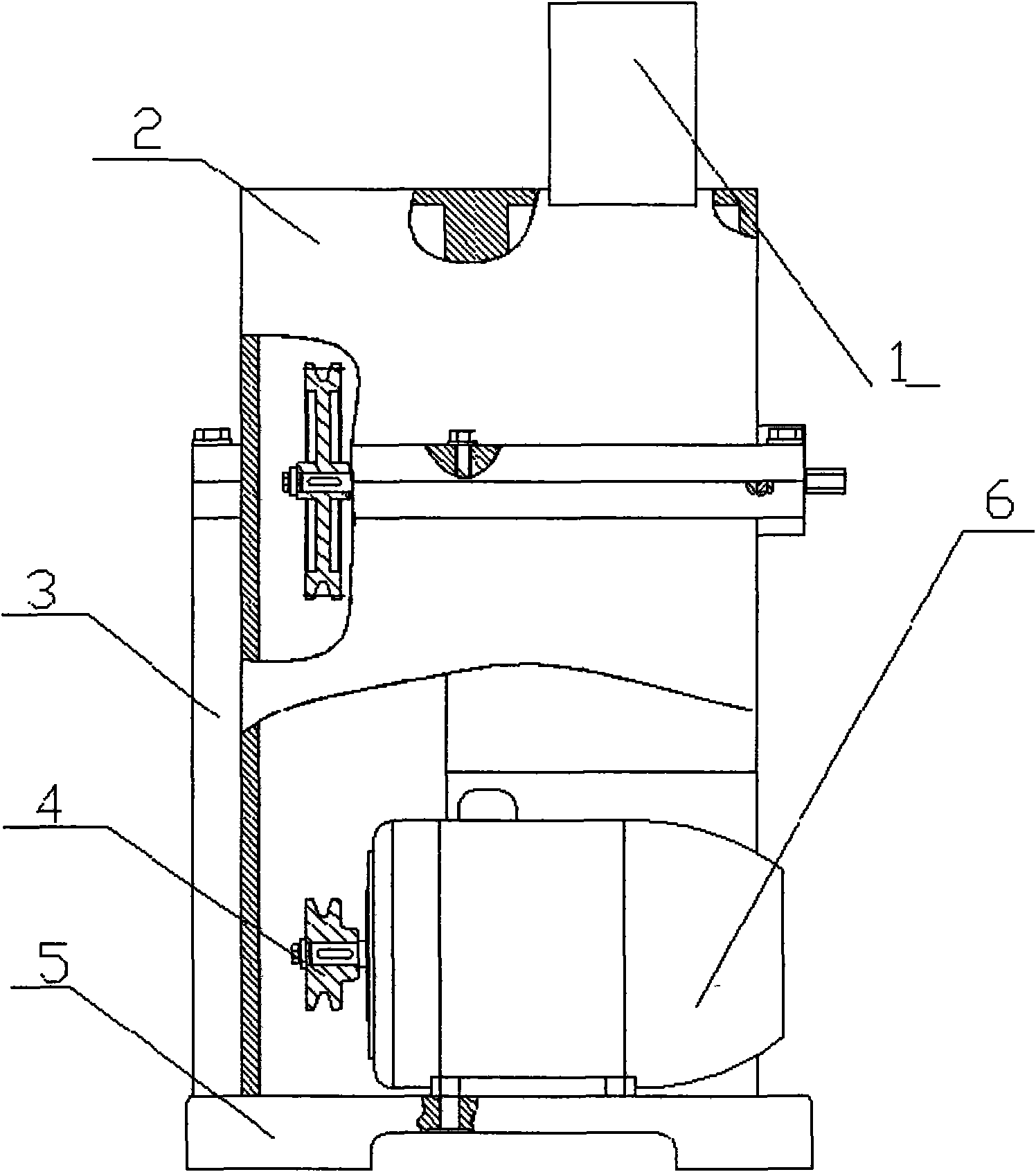

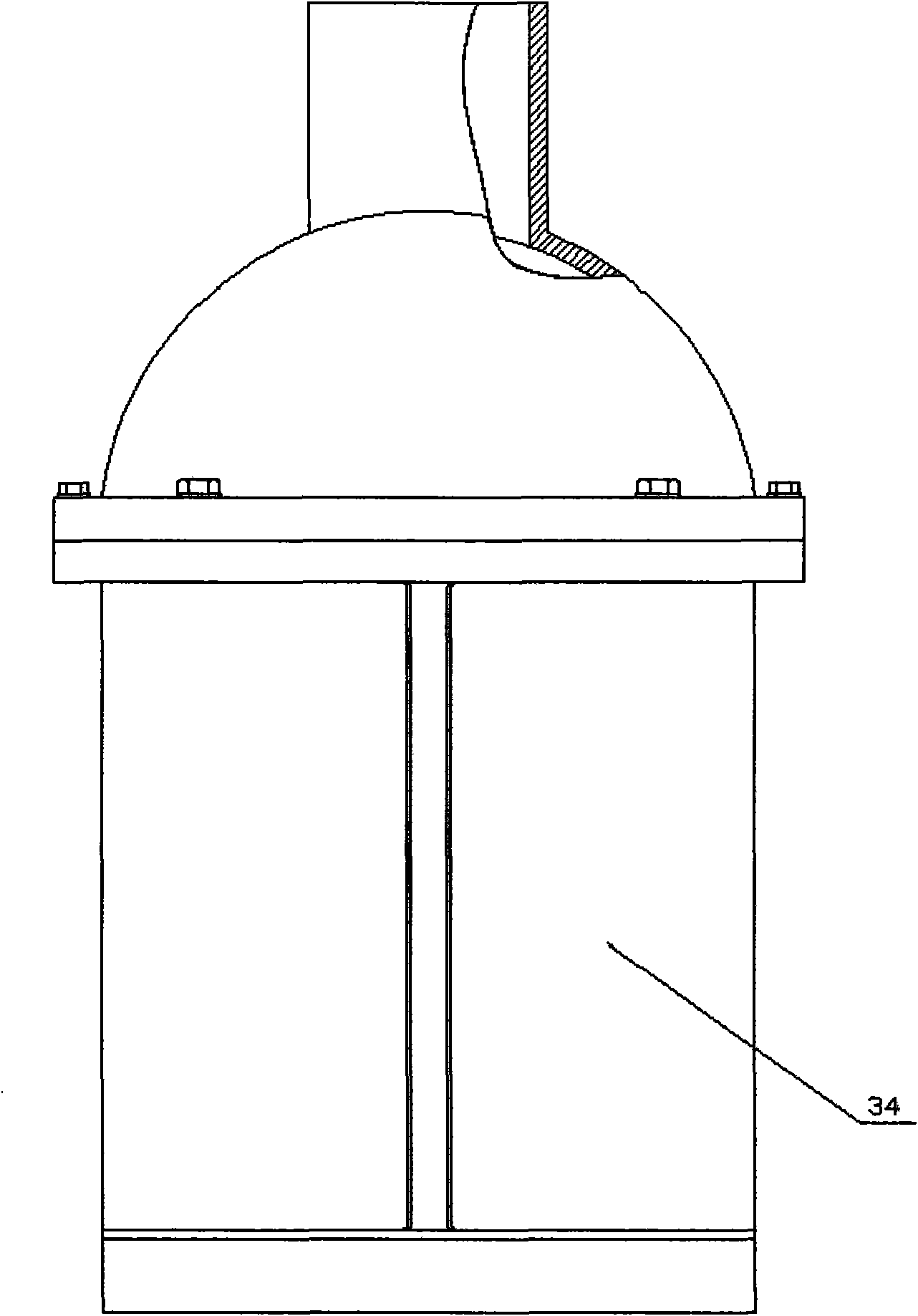

[0043] see figure 1 It is a schematic diagram of the main structure of the food slicer of the present invention and figure 2 As shown in the top view structural diagram of the food slicer of the present invention, a small household food slicer includes a pair of special cutters 20 and a motor 6. The motor 6 is installed on the base 5 and is positioned at the motor in the lower box 34. In the fixed chamber 25, after passing the motor shaft through the shaft hole of the lower box, install the motor pulley 4 at the end of the shaft, fix the lower box 34 on the base 5, and connect the motor pulley 4 and the transmission pulley 11 with a V-belt. connected.

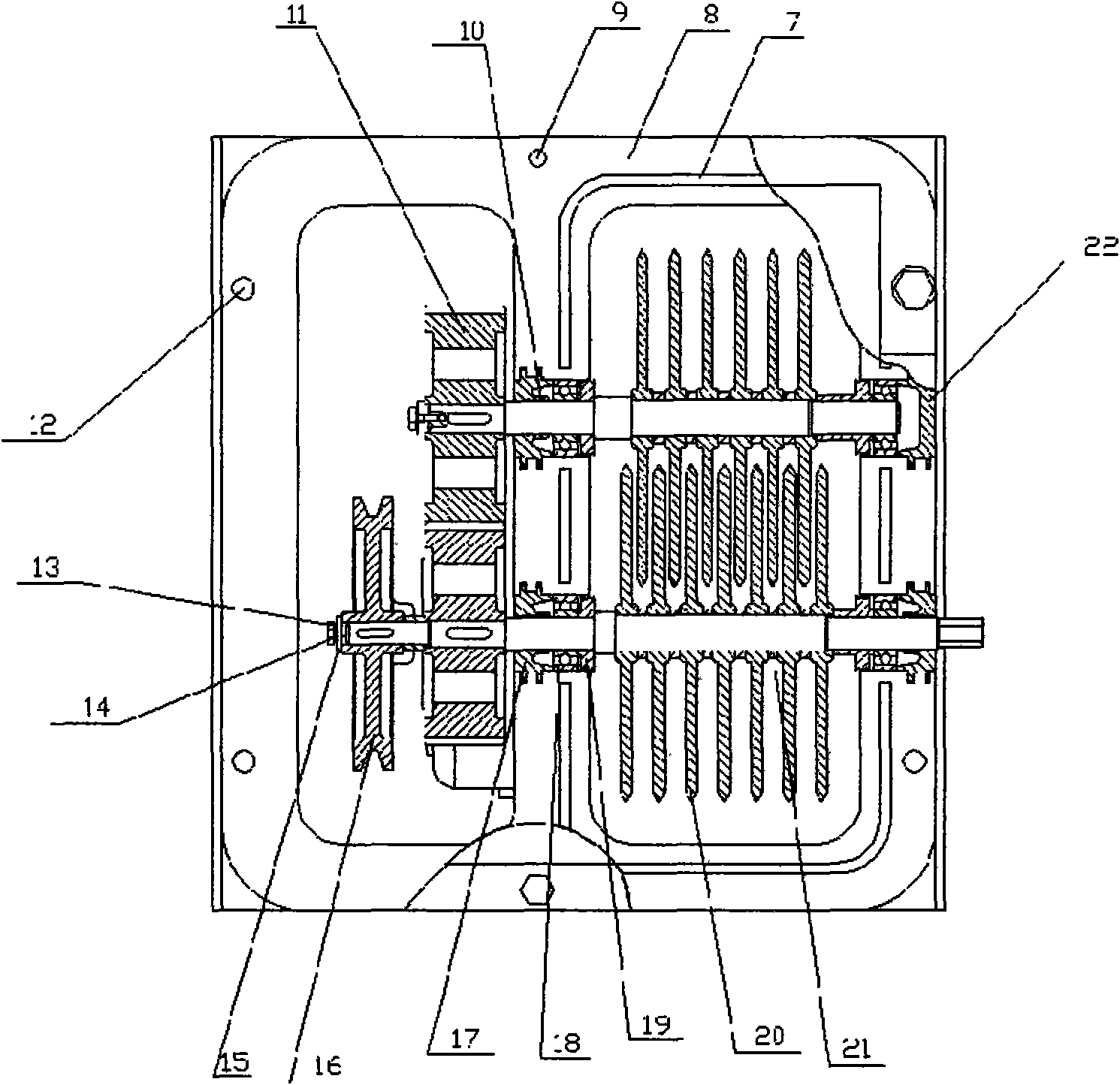

[0044] see figure 2 It is the top view structure schematic diagram of the present invention and Figure 5The structural diagram of the top view of the box body, the cutter 20 is installed on the driving shaft 35 and the driven shaft 36 in the cutter transmission mechanism, the sleeve 21 is installed between two adjacent cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com