Multi-stage phase change spray granulation nozzle for granulating asphalt residues

A spray granulation and nozzle technology, applied in the field of flash spray granulation nozzles, can solve the problems of low density, difficult storage and transportation of asphalt granules, and achieve the effect of simple structure and convenient storage and transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

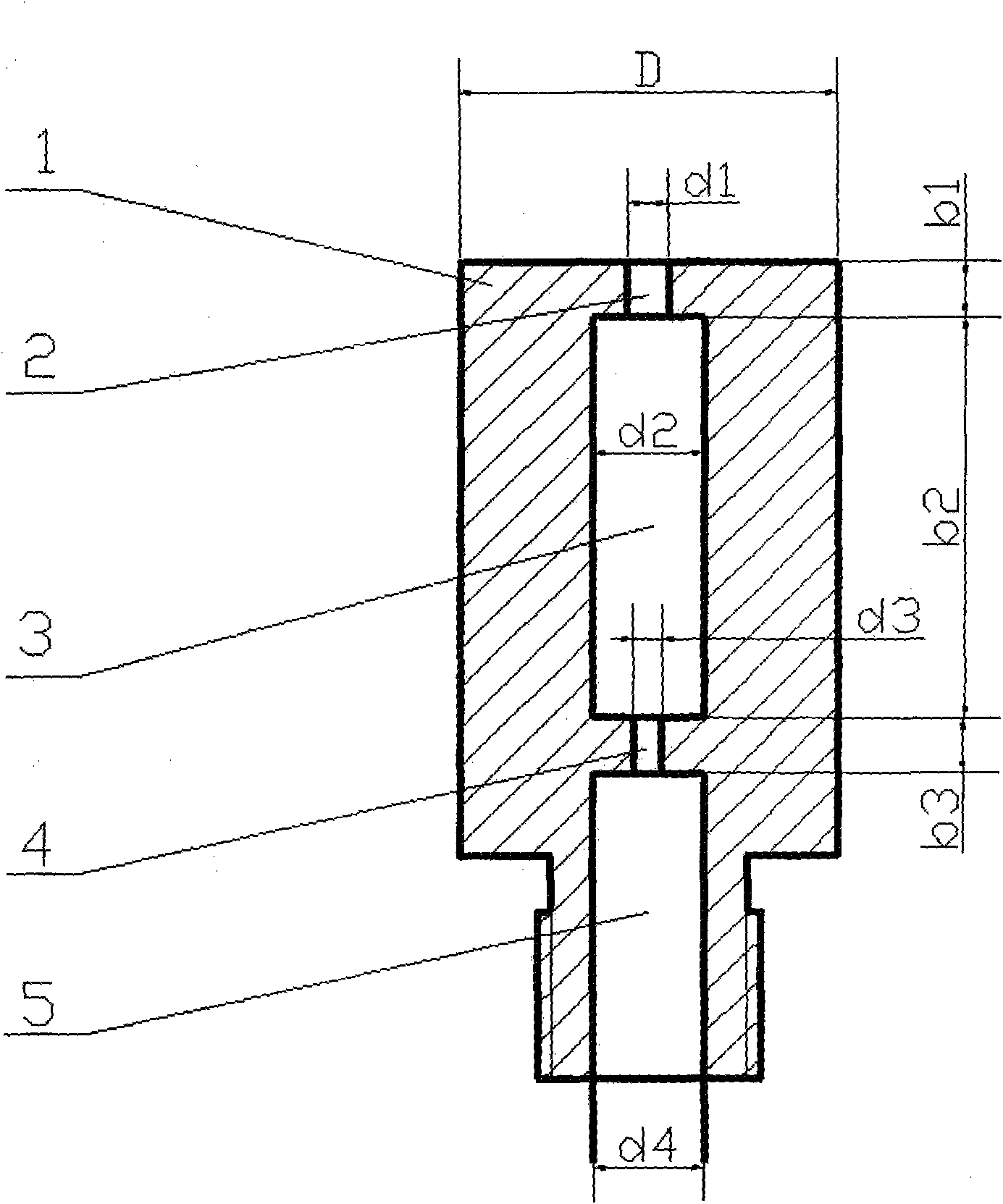

[0013] The working process of the nozzle of the present invention will be described below in conjunction with the accompanying drawings.

[0014] refer to figure 1 , the secondary nozzle 2 is cylindrical, with a diameter of d1 and a height of b1, and the variation range of b1 is 0.2d1-50.0d1. The throttling expansion cavity 3 is a cylindrical cavity with a diameter of d2 and a height of b2. The front part is connected with the secondary nozzle 2, and the rear part is connected with the primary nozzle 4; the variation range of d2 is 0.1d1 ~20.0d1, and the range of b2 is 1.0d1~100.0d1. The primary nozzle 4 is cylindrical, with a diameter of d3 and a height of b3. The variation range of d3 is 0.1d1-5.0d1, and the variation range of b3 is 0.2d1-50.0d1. The inlet 5 of the nozzle is cylindrical, and the variation range of the inner diameter d4 of the inlet is 1.5d1-20.0d1.

[0015] The use process of the multistage phase change spray granulation nozzle of the present invention ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com