Aluminum pot

An aluminum pot and aluminum technology, applied in the field of tableware and pots, can solve the problems of hot objects in the pot hurting people, protruding bottom of the pot, unstable rotation, etc., achieve good heating effect, increase the thickness of the heating layer, and reduce the heat easily deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described in detail below with reference to the embodiments of the accompanying drawings.

[0044] Example 1

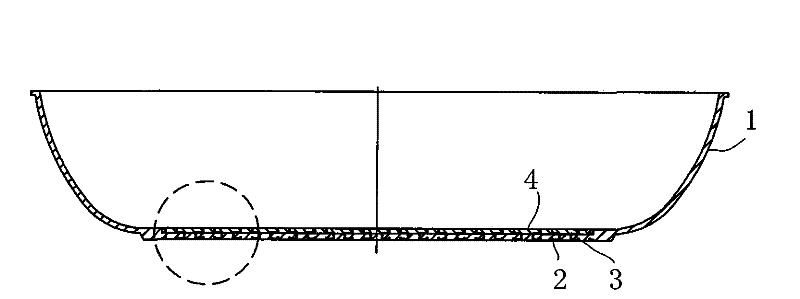

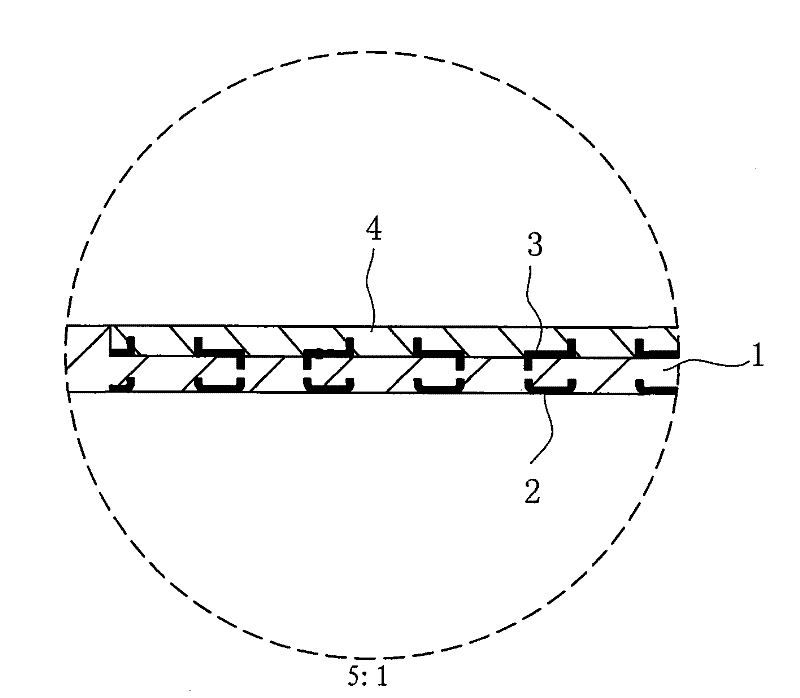

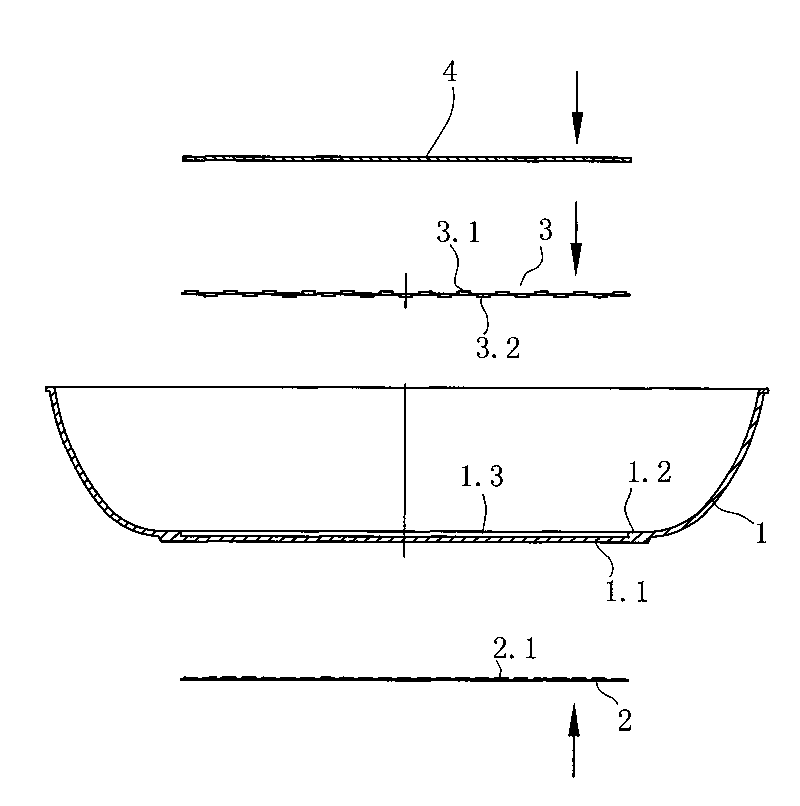

[0045] like Figure 1-3 The shown aluminum pot has a magnetically conductive heating plate fixed on the bottom of the aluminum pot. The key point of the invention is that the lower surface 1.1 of the bottom of the pot The surface 1.2 is provided with an accommodating groove 1.3 of suitable shape and thickness, which is usually circular; the magnetic conductive heating plate 2 is made of stainless steel plate with the flip hole 2.1 facing upward, the size and shape are consistent with the bottom of the pot, and then compounded and fixed on the pot The bottom surface of the body 1; another metal connecting plate 3, the surface of which is distributed with downward turning holes 3.2 and upward turning holes 3.1, the size and shape of which are matched with the shape of the accommodating groove 1.3, which can be circular, upwa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com