Steering pump device of double-acting variable vane

A double-acting, steering pump technology, which is applied in the direction of rotary piston pumps, pumps, rotary piston machinery, etc., can solve the problems of loss, pump energy loss, and increased fuel consumption of automobiles, and achieve the effect of reducing energy loss and output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

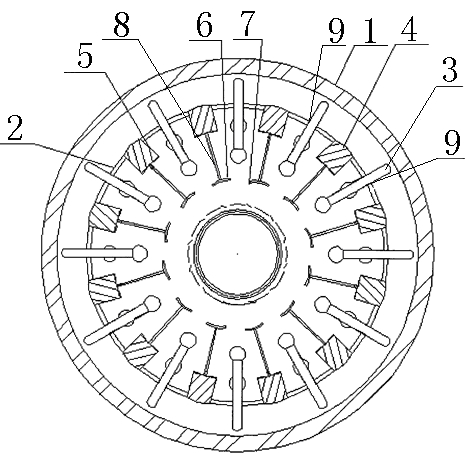

[0012] In order to make the technical means, creative features, objectives and effects of the present invention easy to understand, the present invention will be further explained below with reference to the accompanying drawings.

[0013] Such as figure 1 As shown, taking the working process of a slider 4 between two adjacent blade grooves 9 as an example, since the bottom of the slider 4 has a single-plate spring 7 connected by a long rod screw 8 is set with a pretension force, when the present invention When the steering pump rotates below the set speed, the slider 4 will be firmly pulled by the single spring 7 in the sliding groove 5 and cannot extend outward. At this time, the steering pump will not be able to achieve variable displacement. Will not change. When the rotation speed is greater than the set rotation speed, the centrifugal force applied to the slider 4 is greater than the pretension force of the single leaf spring 7, and the slider 4 slides up and down in the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com