Anti-fatigue high-pressure hydrogen storage container for hydrogen refueling station

A hydrogen storage container and anti-fatigue technology, which is applied to pressure vessels, container filling methods, and outer walls of container structures. Easy to ensure permeability, inhibit the expansion of fatigue lines, and achieve high manufacturing reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Below in conjunction with accompanying drawing, the present invention will be further described.

[0044] The realization process of the inventive method is as follows:

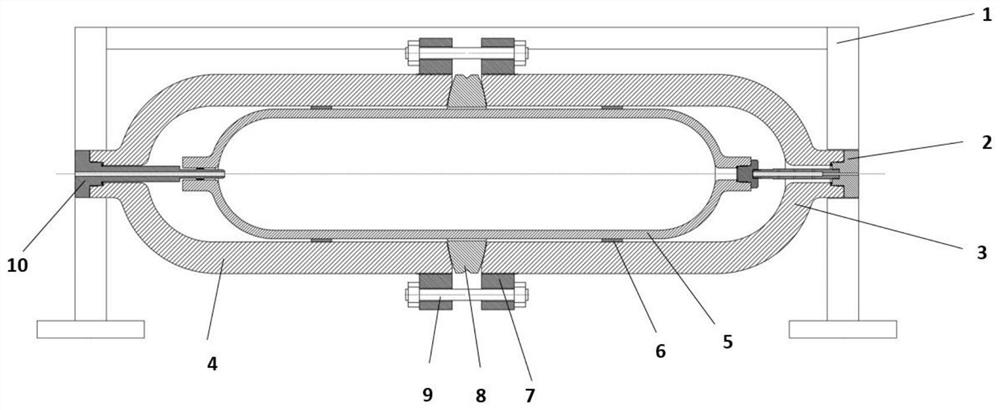

[0045] An anti-fatigue high-pressure hydrogen storage container for a hydrogen refueling station:

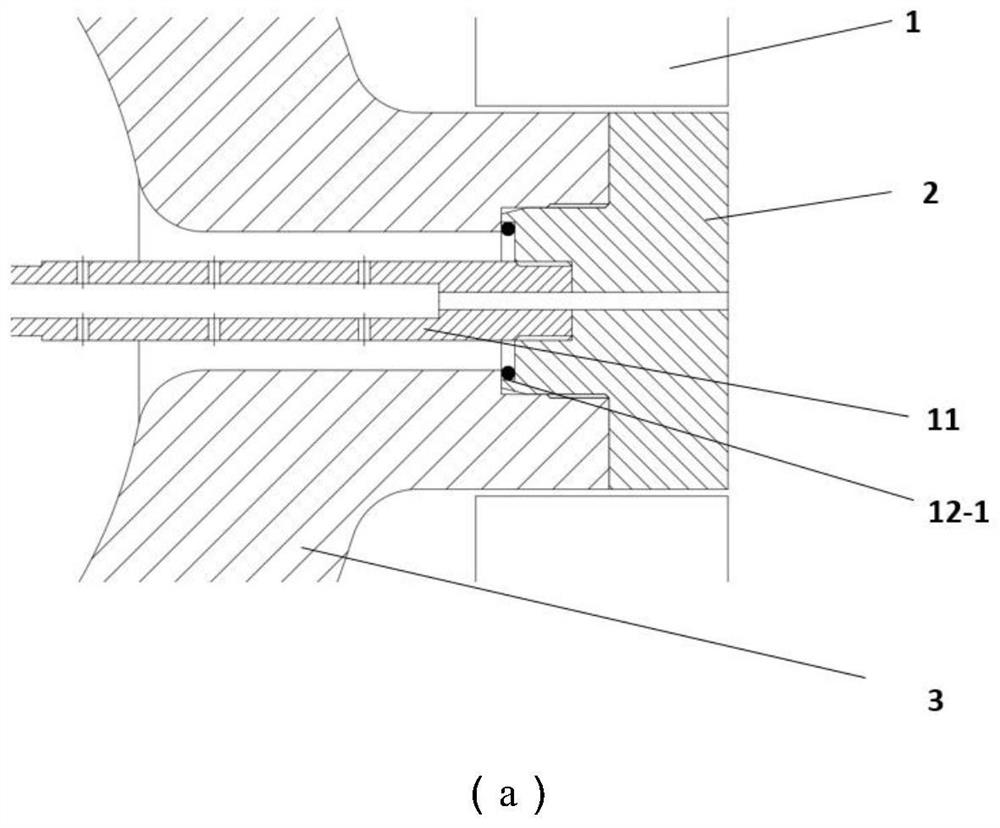

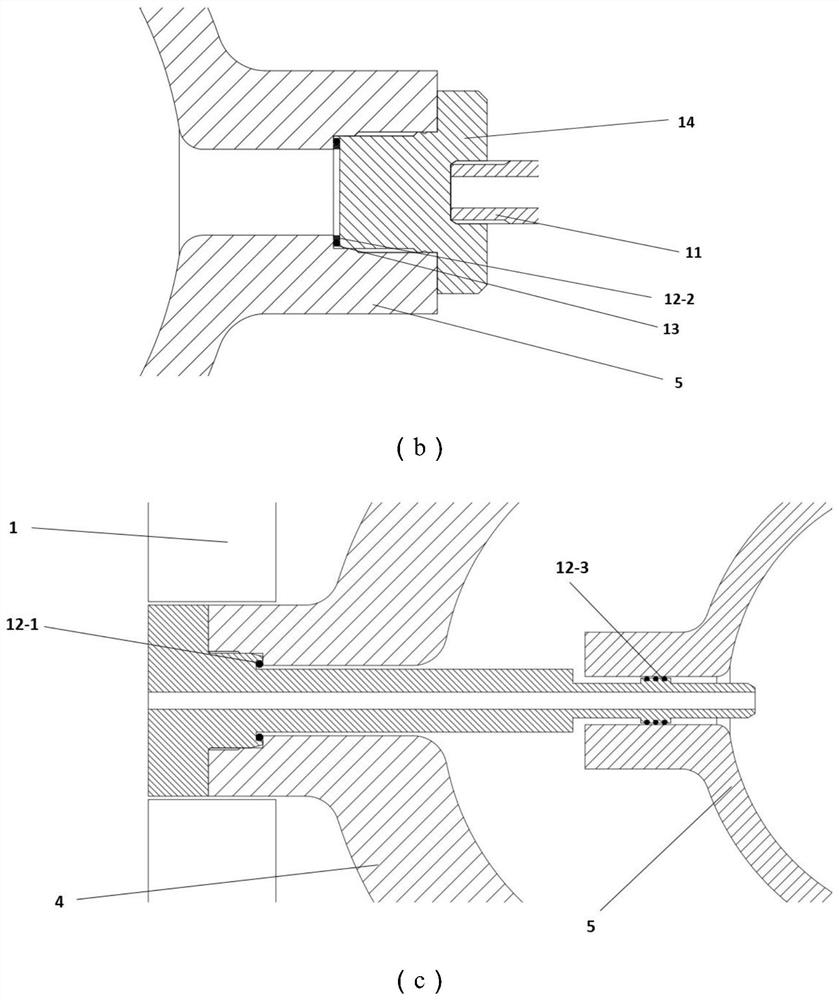

[0046] Assembling the inner container assembly, the inner container sealing ring 12-2 and the sealing ring retaining ring 13 are installed on the sealing surface of the inner container 5 one end bottle mouth, the inner container sealing end cap 14 is connected with the bottle mouth of the inner container 5 by threads, and the The gasket 6 is sleeved on the body of the inner container 5 to complete the assembly of the inner container assembly.

[0047] Assemble the A flap assembly of the outer container, thread the threaded flange 7 with the A flap 3 of the outer container and the B flap 4 of the outer container respectively, and connect the air inlet / outlet end cap 2 of the outer container with the air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com