Polymer/inorganic nanometer composite separation membrane and preparation method thereof

An inorganic nanometer and separation membrane technology, which is applied in semipermeable membrane separation, chemical instruments and methods, membrane technology, etc., can solve problems such as structural defects in the membrane, easy agglomeration of nanomaterials, poor selectivity, etc., and achieve simple preparation process operation Ease of operation, increased selectivity and transmittance, and controllable orientation of nanomaterials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

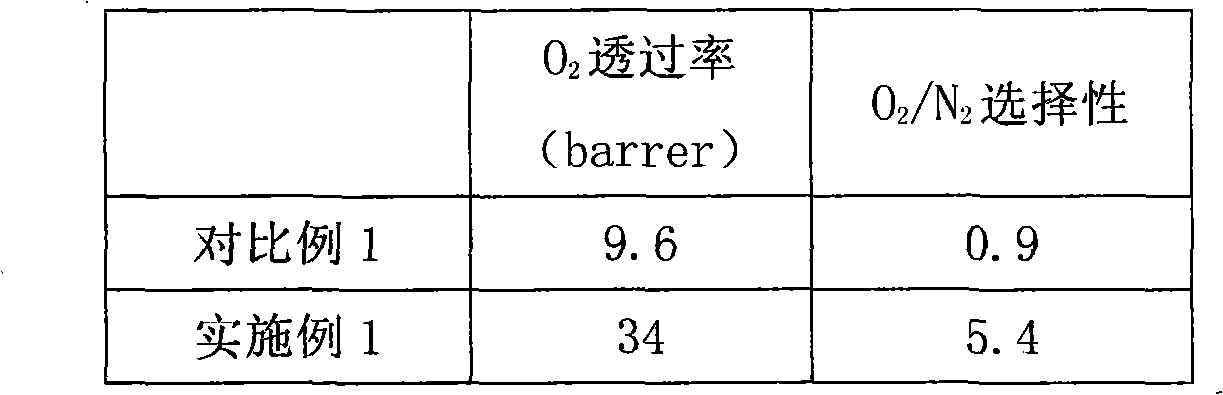

Embodiment 1

[0034] Weigh poly(amide-imide) (PAI) and dissolve it in N-methylpyrrolidone (NMP) to prepare a 200 mg / ml solution, labeled as A; weigh graphene oxide (GO), and ultrasonically disperse it into NMP, A 1.2 mg / ml solution was prepared and labeled as B. Measure 0.25ml of A and 0.25ml of B to mix, sonicate for 20min, stir mechanically for 1h, then transfer the mixed solution to the surface of a glass substrate with an applied electric field for film formation. The direction of the applied electric field is perpendicular to the surface of the glass substrate. The electric field strength is 100v / mm. After the composite film is basically dried, put it in an oven to dry at 150°C for 1 hour to obtain the finished polymer / inorganic nanocomposite film. The orientation of the graphene oxide in this finished product is perpendicular to the plane of the film.

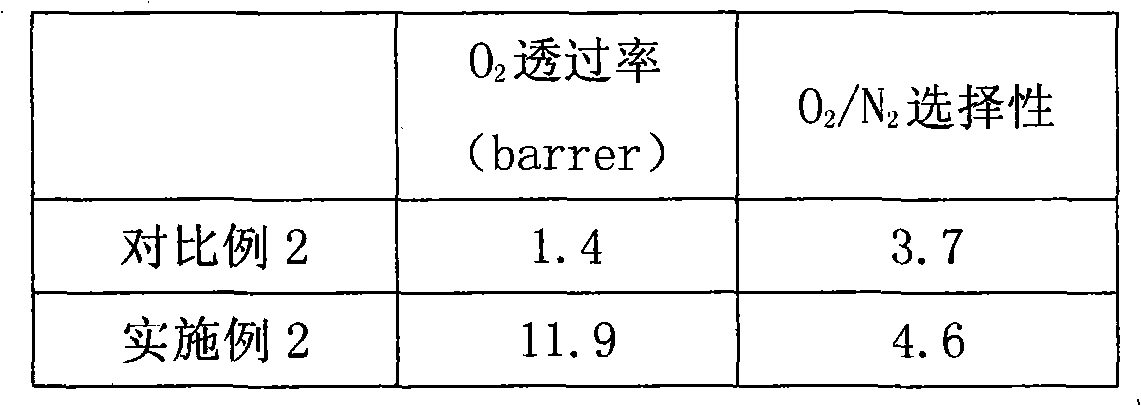

Embodiment 2

[0036] Weigh poly(amide-imide) (PAI) and dissolve it in N-methylpyrrolidone (NMP) to prepare a 100 mg / ml solution, labeled A; weigh graphene oxide (GO), and ultrasonically disperse it into NMP, A 0.2 mg / ml solution was prepared and marked as B. Measure 0.25ml of A and 0.25ml of B to mix, sonicate for 20min, stir mechanically for 1h, then transfer the mixed solution to the surface of a glass substrate with an applied electric field for film formation. The direction of the applied electric field is parallel to the surface of the glass substrate. The electric field strength is 150v / mm. After the composite film is basically dried, put it in an oven to dry at 150°C for 1 hour to obtain the finished polymer / inorganic nanocomposite film. The orientation of the graphene oxide in this finished product is parallel to the film plane.

Embodiment 3

[0038] Weigh polyvinylidene fluoride (PVDF) and dissolve it in N-methylpyrrolidone (NMP) to prepare a 200 mg / ml solution, marked as A; weigh multi-walled carbon nanotubes (CNTs), and ultrasonically disperse them evenly in NMP to prepare 1.2 mg / ml solution, labeled B. Measure 0.25ml of A and 0.25ml of B to mix, sonicate for 20min, stir mechanically for 1h, then transfer the mixed solution to the surface of a glass substrate with an applied electric field for film formation. The direction of the applied electric field is perpendicular to the surface of the glass substrate. The electric field strength is 50v / mm. After the composite film is dried, the finished polymer / inorganic nanocomposite film is obtained. The orientation of the carbon nanotubes in the finished product is perpendicular to the plane of the film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com